Flat die biomass granulation equipment with particle online image analysis control

An image analysis and biomass technology, applied in the direction of granulating raw materials, analyzing materials, chemical/physical processes, etc., can solve the problem of unfavorable granulation product quality assurance, easy to cause misreading and misjudgment, and cannot be online in real time, etc. problems, to reduce labor costs, avoid rework waste, and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to more fully explain the implementation of the present invention, the implementation examples of the present invention are provided, and these implementation examples are only illustrations of the present invention, and do not limit the scope of the present invention.

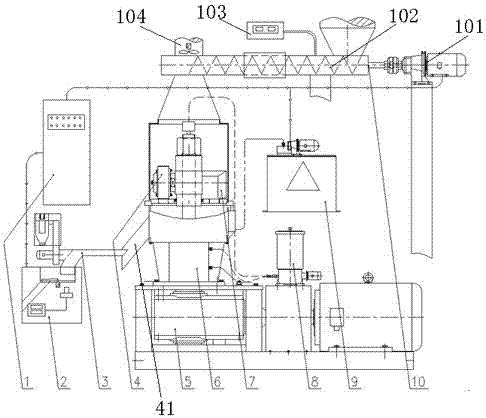

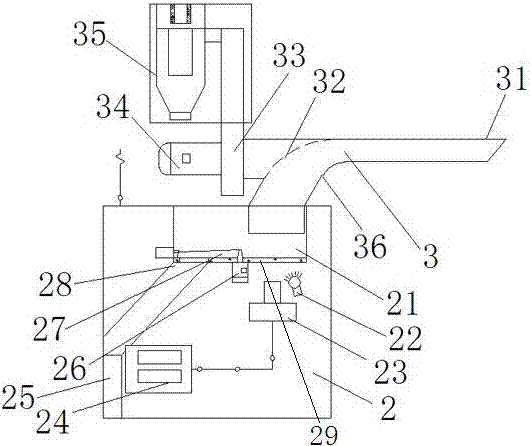

[0010] The present invention is further described in detail in conjunction with the accompanying drawings, each of which is marked as: 1: control part; 2: image acquisition and analysis system; 21: image acquisition room; 22: lighting compensation device; 23: camera; 24: computer; 25: Sample collection box; 26: Cleaning motor; 27: Cleaning arm; 28: Sample cleaning slide; 29: Image collection window; 3: Sampling device; 31: Sampling tube; 32: Curved screen; 33: Fan; 34: vacuum generator; 35: dust removal device; 36: feeding chute; 4: granulation part; 41: discharge port; 5: power part; 6: main shaft part; 7: circumferential distributor; 8: lubrication Part; 9: Compression force adjustment system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com