Grain extruder

An extruder, food technology, applied in food science, food forming, application and other directions, can solve the problems of easy leakage of lubricating oil, unstable work, complex structure, etc., to ensure good lubrication, improve puffing effect, and improve heat transfer. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Figure 7 The direction indicated by the arrow in is the flow direction of lubricating oil in the pipeline (overflow oil pipe and oil return pipe).

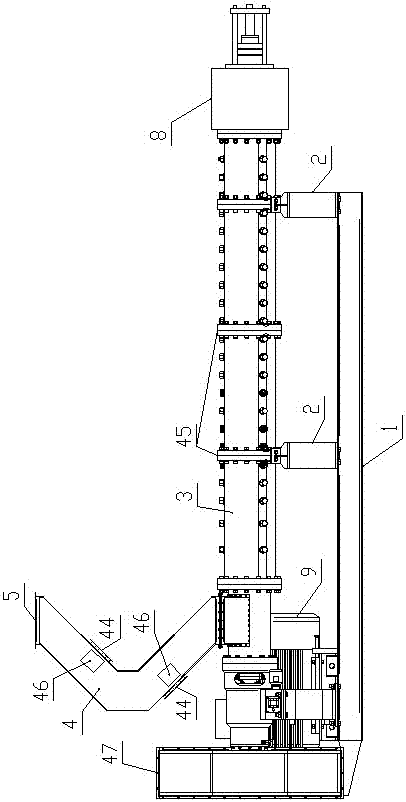

[0047] Such as Figure 1 to Figure 14As shown, the grain puffing machine of the present invention includes a machine base 1, and the machine base 1 is connected with a cylindrical squeeze chamber 3 through a plurality of support frames 2 arranged at intervals. One end of the squeeze chamber 3 is a feed end and the other end is a discharge end. end; the feeding end of the pressing chamber 3 is upwardly connected with a feeding pipe 4, and the top of the feeding pipe 4 is provided with a feeding port 5; the side of the feeding end of the pressing chamber 3 is its front side ( figure 1 and figure 2 One side of the medium and large pulley 6 is the front side of the present invention) and the side of the discharge end of the press chamber 3 is its rear side ( figure 1 and figure 2 Middle discharge tail box 8 one side is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com