Intelligent photovoltaic component multifunctional junction box

A photovoltaic module and multi-functional technology, applied in photovoltaic power generation, photovoltaic modules, electrical components, etc., can solve problems such as high manpower and material costs, damaged power generation performance, broken or dropped cable interfaces, and reduce operation and maintenance costs , avoid wear and tear, easy maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

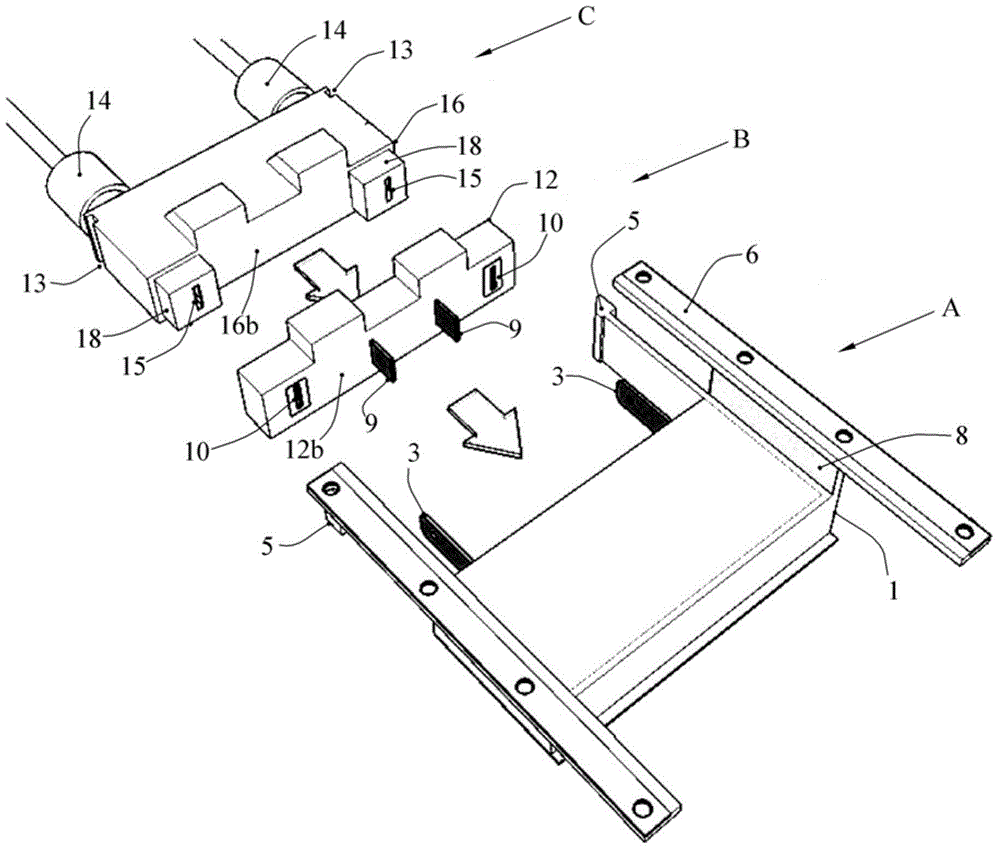

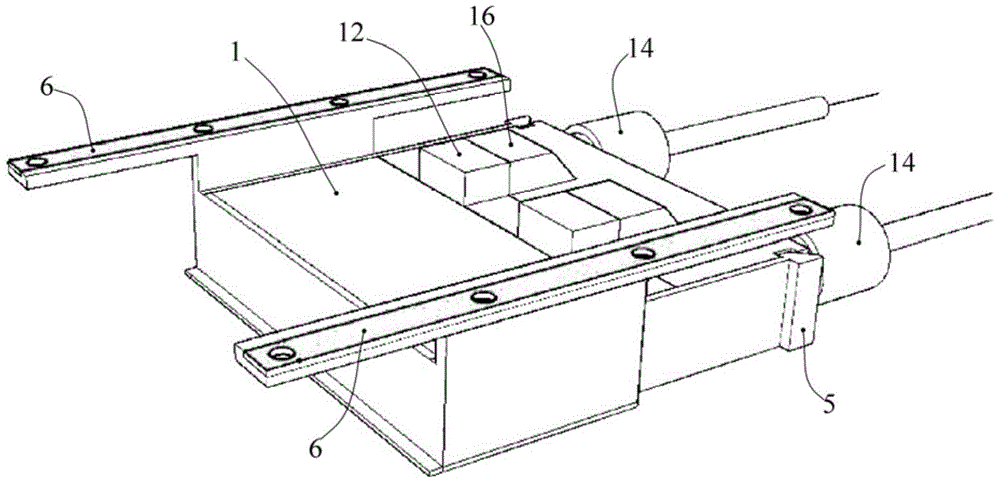

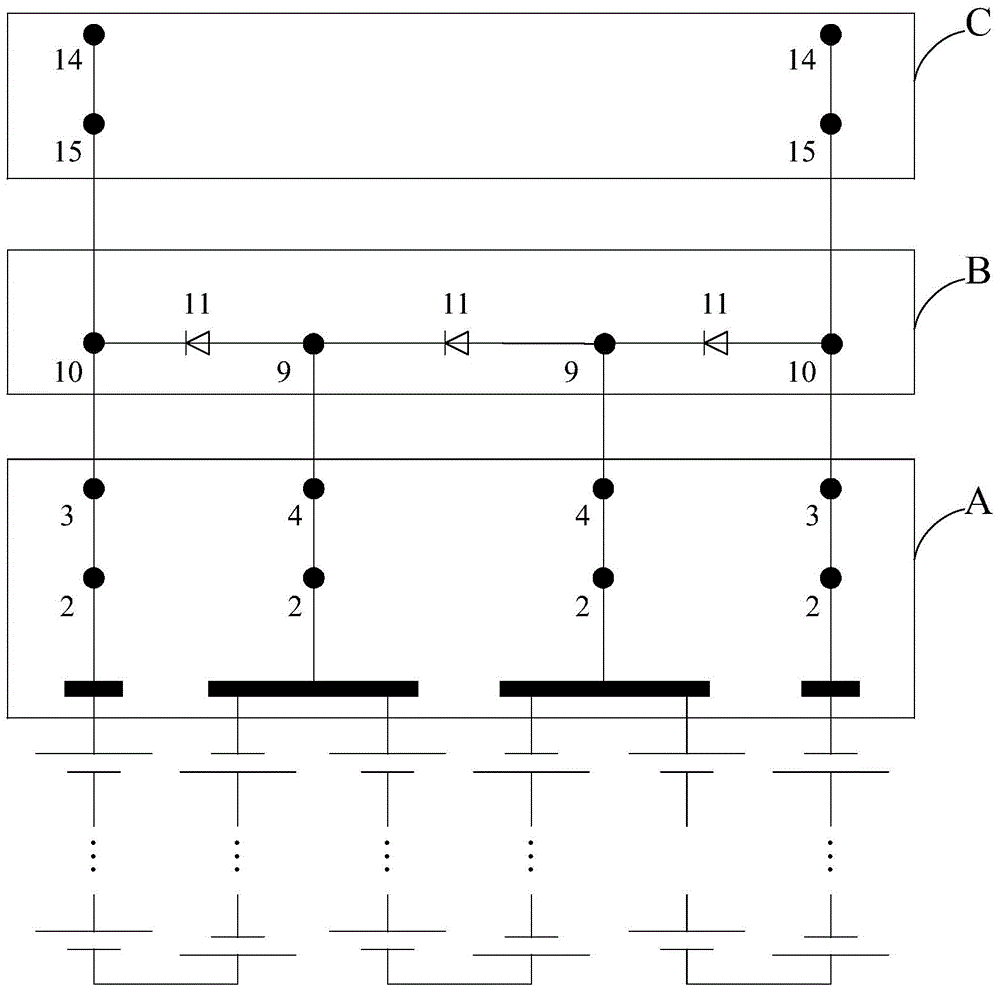

[0063] Such as Figure 1-1 to Figure 4As shown, the smart photovoltaic module multifunctional junction box according to Embodiment 1 of the present invention can be used to connect three strings of solar cell strings, which include a horizontal base module A, a horizontal diode module B and a horizontal cover module C.

[0064] The above-mentioned horizontal base module A is provided with a horizontal base insulating shell 1, four conductive posts 2 installed in the horizontal base insulating shell 1, two horizontal base conductive inserts 3 and two horizontal base conductive inserts. Holes 4, wherein, the bottom surface of the horizontal base insulating shell 1 is provided with openings 7 for introducing photovoltaic module bus bars, two horizontal base conductive inserts 3 and two horizontal base conductive jacks 4 are respectively connected with four The conductive columns 2 are electrically connected in a one-to-one correspondence, and the two horizontal base conductive in...

Embodiment 2

[0077] Such as Figure 5-1 to Figure 8 As shown, the multifunctional junction box of the smart photovoltaic module according to the second embodiment of the present invention can be used to connect three strings of solar cell strings, which include a vertical base module VA, a vertical diode module VB and a vertical cover module VC.

[0078] The above-mentioned vertical base module VA is provided with a vertical base insulating shell V1 and four conductive pillars 2 installed in the vertical base insulating shell V1, two vertical long base conductive inserts V3 and two vertical short Type base conductive insert V4, wherein, the bottom surface of the vertical base insulating shell V1 is provided with an opening 7 for introducing the bus bar of the photovoltaic module, two vertical long base conductive inserts V3 and two vertical short bases The conductive inserts V4 are respectively electrically connected to the four conductive pillars 2 in a one-to-one correspondence and are e...

Embodiment 3

[0091] Such as Figure 9 As shown, the multifunctional junction box of the smart photovoltaic module in the third embodiment of the present invention is basically the same as the first embodiment, and their difference is that the multifunctional junction box of the smart photovoltaic module in the third embodiment also includes a horizontal smart electronic module D, The horizontal intelligent electronic module D is provided with a horizontal intelligent electronic module insulating housing 19 and an intelligent electronic circuit unit installed in the horizontal intelligent electronic module insulating housing 19 and two horizontal intelligent electronic modules conduct electricity. Socket holes 20, wherein the intelligent electronic circuit unit is electrically connected to the conductive socket holes 20 of the two horizontal intelligent electronic modules respectively, and the conductive socket holes 20 of the two horizontal intelligent electronic modules are all in the hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com