Micro-stepping low-noise stepping motor drive controller

A stepper motor, low noise technology, applied in the direction of motor generator control, control system, electrical components, etc., can solve the problems of obvious heat generation, high noise, low step accuracy, etc., achieve low heat generation, low audio noise, low The effect of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

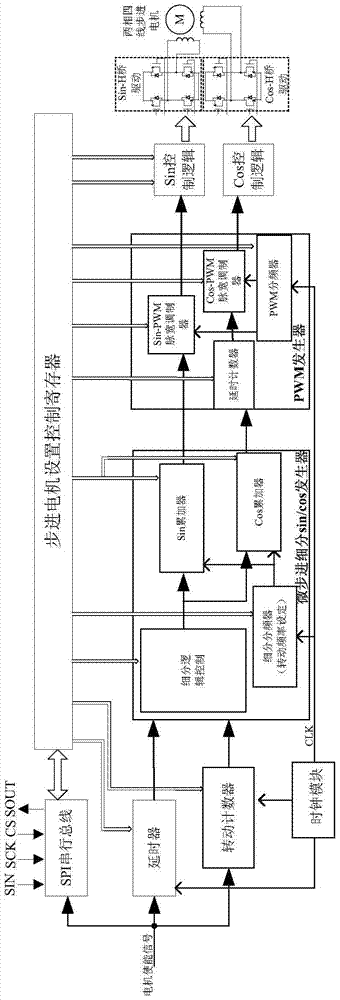

[0033] Now in conjunction with accompanying drawing, the present invention will be further described:

[0034] As shown in the figure, a micro-stepping low-noise stepping motor drive controller includes:

[0035]The stepper motor sets the control register, which is connected to the external device through the SPI serial bus, the SPI serial bus is also connected to the motor enable signal, and the motor enable signal is connected to the external device; the SPI serial bus has SIN, SCK, CS, SOUT port.

[0036] Delay device, the data input end is connected to the stepper motor setting control register, which is used to receive the delay time information when the motor starts to rotate, and the control end is connected to the motor enable signal;

[0037] Rotation counter, the data input terminal is connected to the stepper motor setting control register, which is used to receive the setting information of the number of motor rotation steps, and the control terminal is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com