Fin type field effect transistor structure and manufacturing method thereof

A technology of fin field effect and fabrication method, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of difficulty in controlling the width of fins, complex process steps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the content of the present invention clearer and easier to understand, the content of the present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

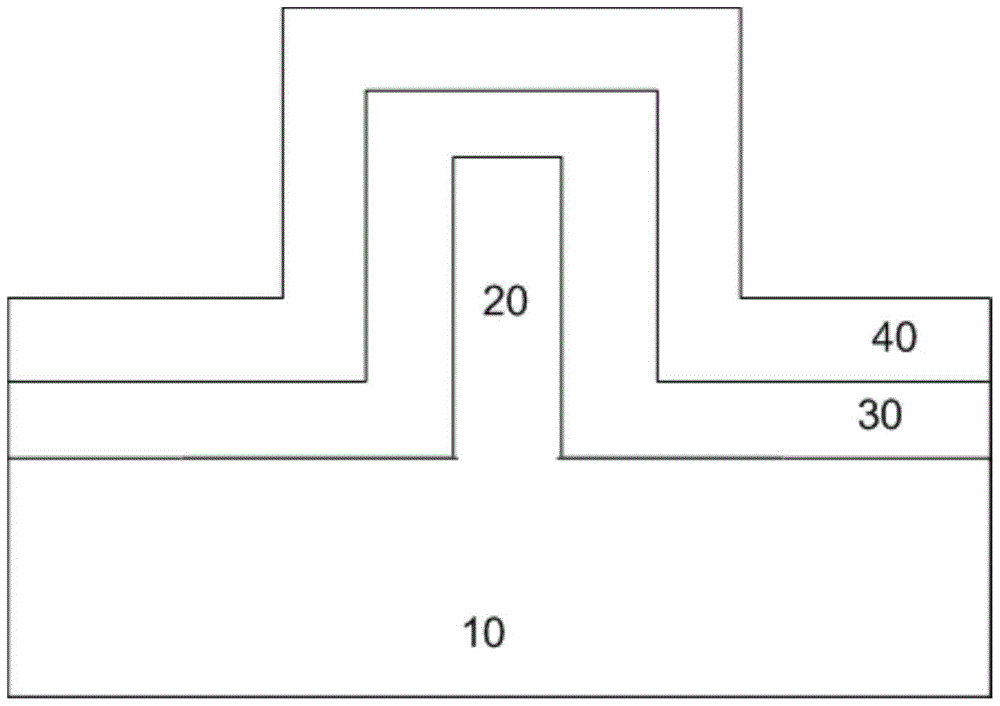

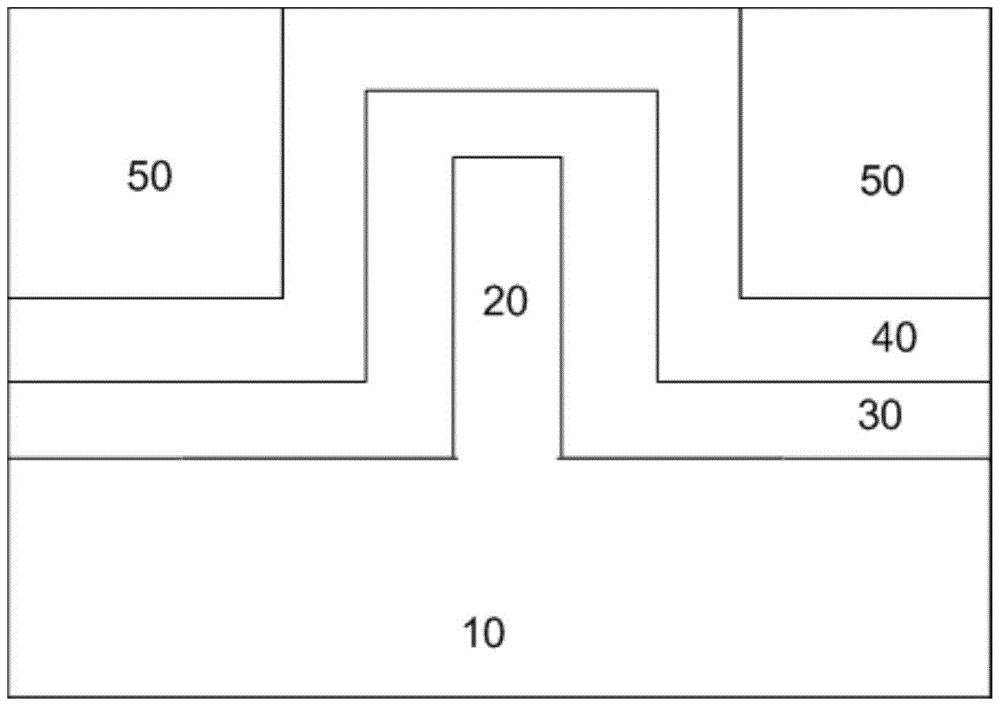

[0031] A preferred embodiment of the present invention provides a method of forming a fin structure. Among them, an initial fin structure is formed on Si by photo / etch, and SiGe / Si / SiGe / … multilayer films are epitaxially grown on the initial fin structure in sequence, and then grooves are formed in the multilayer films by removing SiGe. Fill the groove with silicon oxide, and then remove excess Si and SiGe by polishing or etching. SiGe is further etched back to form a multi-Si fin structure.

[0032] Of course, the epitaxial materials are preferably SiGe and Si, but the present invention is not limited to these two materials, SiGe and Si.

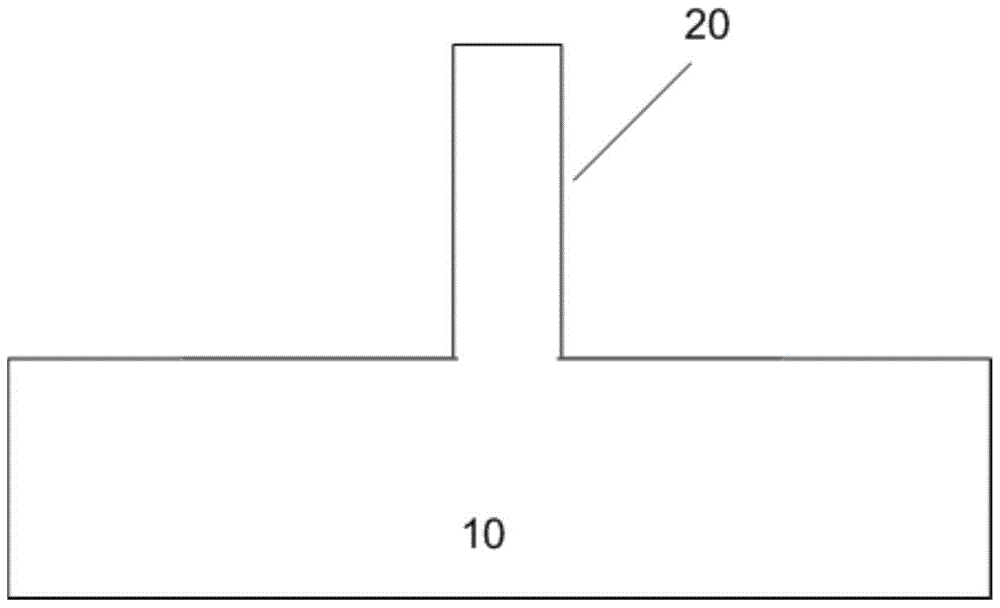

[0033] specifically, Figure 1 to Figure 6 Each step of the fabrication method of the fin field effect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com