Self-balancing high heavy level load loading method and device

A self-balancing, horizontal position technology, which is applied in the testing of measuring devices, instruments, machines/structural components, etc., can solve problems such as the inability to achieve full-scale load levels, complex assembly of test benches, and large loading tonnage, and achieve a force transmission system Improve and overcome the effect of too small load level and convenient loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

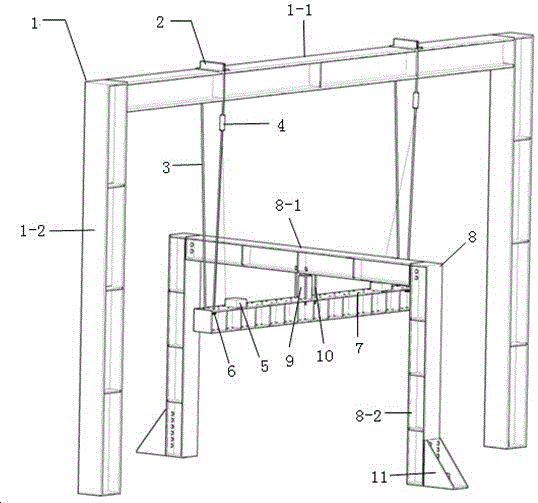

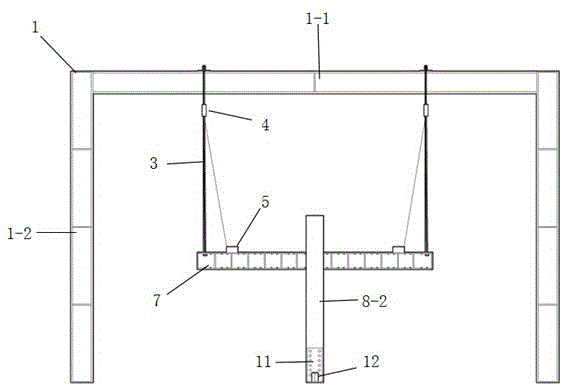

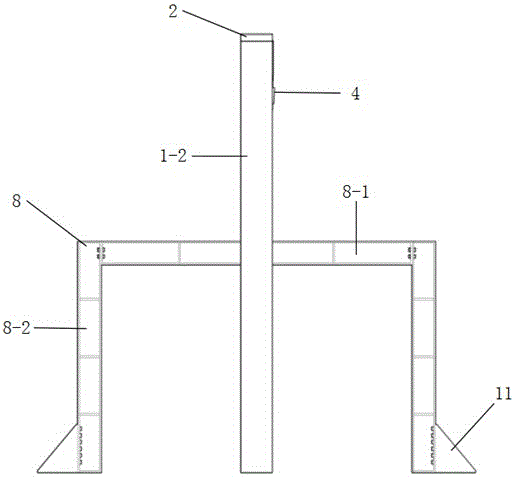

[0016] Such as figure 1 shown, as figure 1 , 2 , 3, 4, 5, and 6, the self-balancing high-position heavy-duty load loading method and its device include a load-bearing frame 1, a load-bearing frame beam 1-1 and a load-bearing frame column 1-2, and the load-bearing frame 1 consists of a parallel position The load-bearing frame beam 1-1 is composed of the load-bearing frame column 1-2 in the horizontal position, and the load-bearing frame beam 1-1 is provided with two limit steel angles 2, and the limit steel angle 2 is connected with the steel wire rope 3, and the steel wire rope 3 is provided with The tension sensor 4 and the steel wire rope 3 are connected to the end of the force transmission distribution beam 7 through the steel wire rope fixer 6. The force transmission distribution beam 7 is provided with a tension sensor display 5, and the force transmission distribution beam 7 is provided with a jack 9 and a reaction force pull rod 10. A reaction force frame 8 is placed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com