Medium-low-temperature hot source heat pump steam system

A low-temperature heat source and steam system technology, applied in heat pumps, steam generation, steam generation methods, etc., can solve problems such as low energy saving effect and complex structure, and achieve the effects of avoiding wet compression, expanding application range, and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

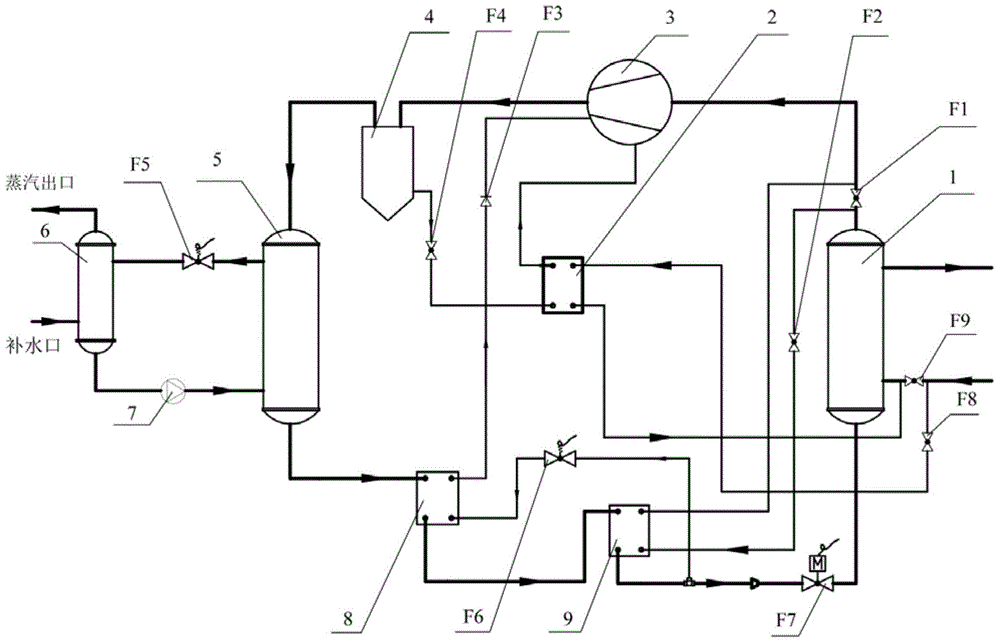

[0017] Such as figure 1 As shown, a medium and low temperature heat source heat pump steam system includes a heat pump circulation loop through which refrigerant passes and a flash evaporation circulation loop through which flash water passes, wherein the heat pump circulation loop is provided with an evaporator 1, a high temperature machine 3, oil separator 4, condenser 5, economizer 8, subcooler 9 and electronic expansion valve F7, the evaporator 1 is connected with a medium and low temperature heat source pipeline, and the oil return pipe of the oil separator 4 is connected to The oil pool of the high-temperature compressor 3, the flash circulation circuit is provided with a flash evaporator 6 and a pressurized water pump 7, the flash circulation circuit passes through the condenser 5, and the condenser 5 is located at the outlet of the pressurized water pump 7 Between the inlet of the flash evaporator 6 , the refrigerant outlet pipeline of the evaporator 1 is bypassed with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com