pulverized coal burner

A pulverized coal burner and pulverized coal technology, applied in the direction of burners, burners burning powder fuel, combustion methods, etc., can solve problems such as difficult to achieve combustion state and environmental protection emission standards, achieve more complete combustion stability, improve The effect of burnout and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

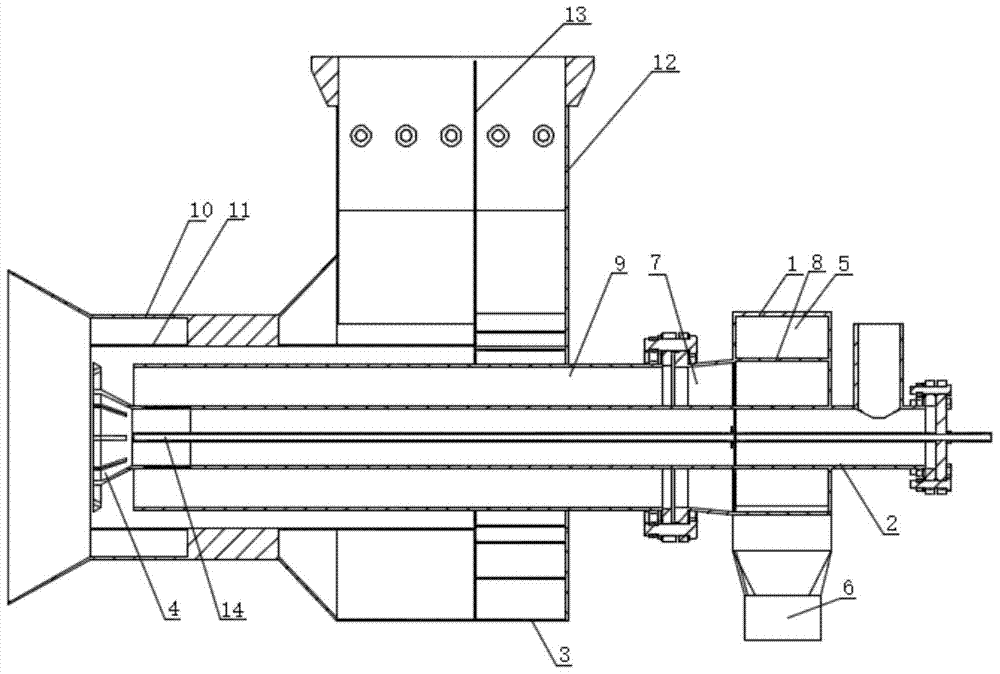

[0026] The present invention will be further described below in conjunction with accompanying drawing:

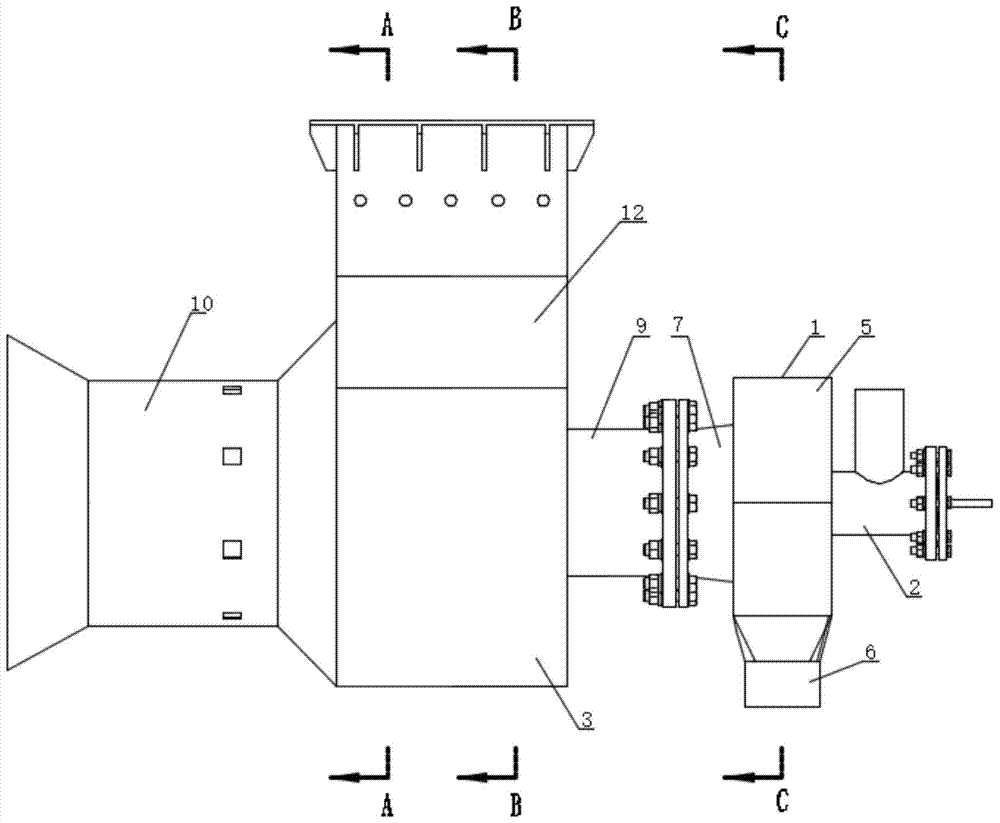

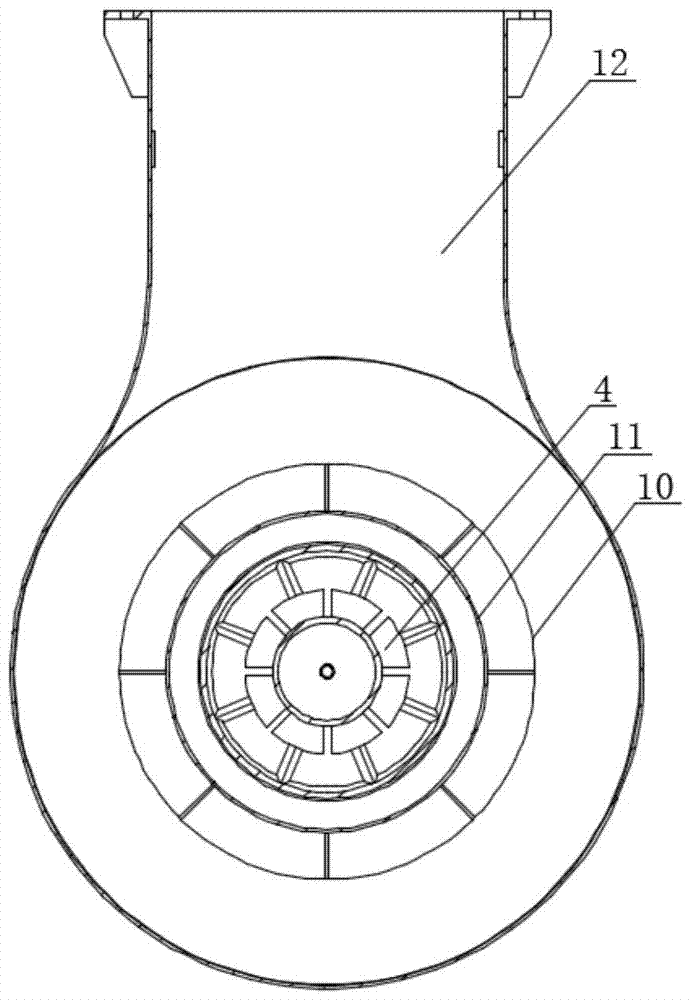

[0027] Such as figure 1 , figure 2 As shown, the pulverized coal burner comprises a pulverized coal raw material box 20, a screw feeder 21 and a blast feeding pipeline 22 arranged at the outlet bottom of the pulverized coal raw material box 20, and the blast feeding pipe is arranged at the bottom of the screw feeder 21 and Connect the discharge port of the screw feeder 21, the blast feed pipe is connected to the feed pipe 6 of the burner, and the pulverized coal raw material box 20 is filled with calcium oxide mixed, and the burner includes a feed mixer 1, a central wind Pipe 2, air inlet housing 3, stabilizer 4 and igniter 14, described feed mixer 1 includes cylindrical housing 5, feed pipe 6 and discharge pipe 7, cylindrical housing 5 includes cylinder Shaped side wall and two axial end faces of openings at both ends of the cylindrical side wall, the discharge pipe 7 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com