Coal-fired gasification swirl combustion furnace

A combustion furnace and coal-fired technology, applied in the direction of solid fuel combustion, combustion methods, combustion equipment, etc., can solve problems such as environmental pollution, achieve the effects of prolonging the flame process, improving burnout, and improving exhaust gas purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

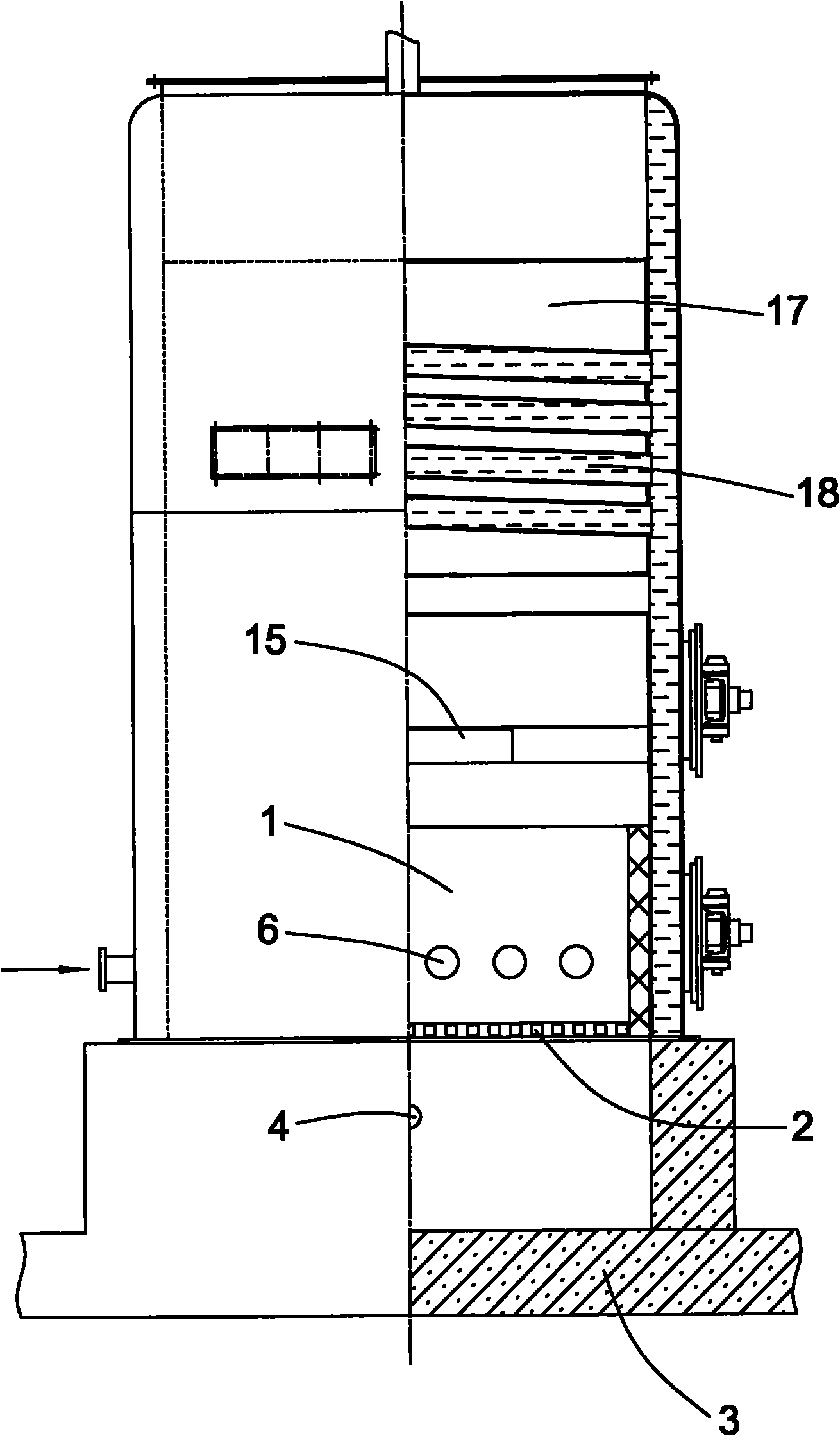

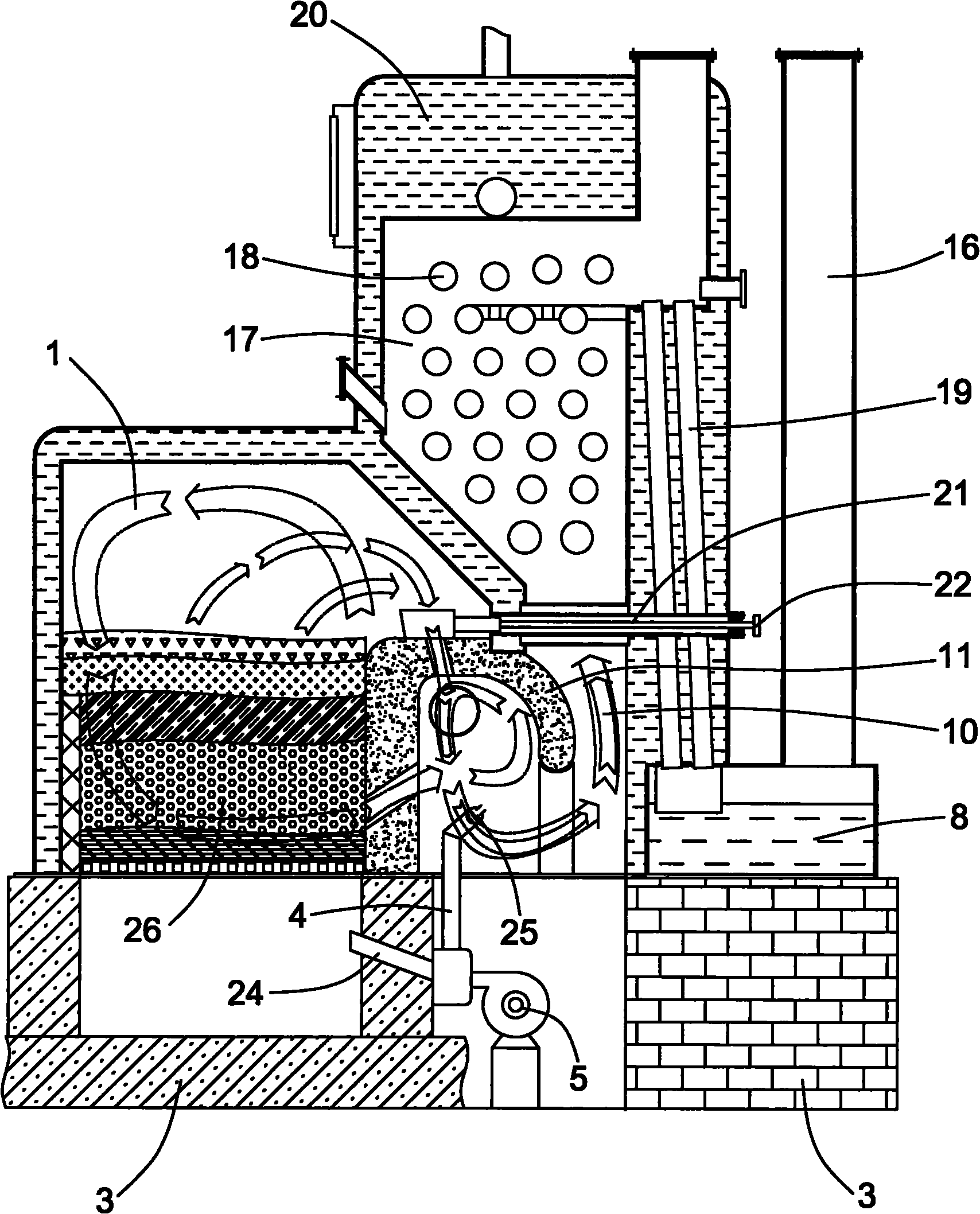

[0017] Labels in the figure:

[0018] 1 furnace, 2 grate, 3 furnace seat, 4 secondary blast pipe,

[0019] 5 blower, 6 fire pipe, 7 partition wall, 8 dust collector,

[0020] 9 flame channel, 10 rear combustion chamber, 11 diversion wall, 12 front combustion chamber,

[0021] 13 oxygen supply hole, 14 gas hole, 15 cover plate, 16 chimney,

[0022] 17 flue, 18 water pipe, 19 smoke pipe, 20 water jacket,

[0023] 21 operating rod, 22 handle, 23 combustion chamber, 24 primary blast pipe,

[0024] 25 air holes, 26 coal.

[0025] Please refer to figure 1 , figure 2 , the present invention is a coal-fired gasification swirling combustion furnace, comprising a hearth 1, a fire grate 2, and a furnace seat 3, the hearth 1 is installed on the hearth 3, the fire grate 2 is installed at the bottom of the hearth 1, and at the bottom of the hearth 1 One side is provided with a combustion chamber 23, the top of the combustion chamber 23 is provided with a flue 17, the side of the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com