Broaching type rock-burst-resistant anchor rod

An anti-rockburst and bolt technology, which is applied to the installation of bolts, sheet pile walls, mining equipment, etc., can solve the problems of cutting chips, affecting the balance distribution of resistance, and being unable to pull out, etc., and achieves the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

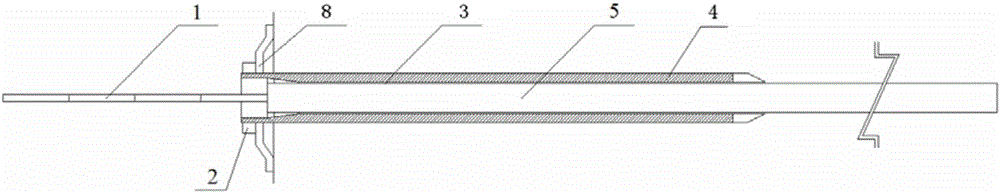

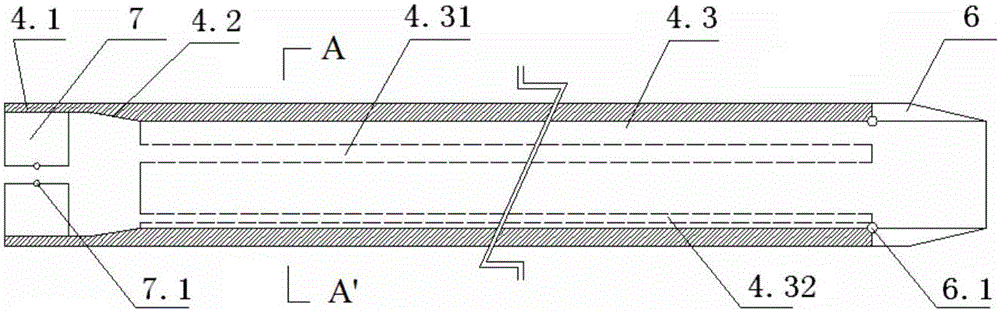

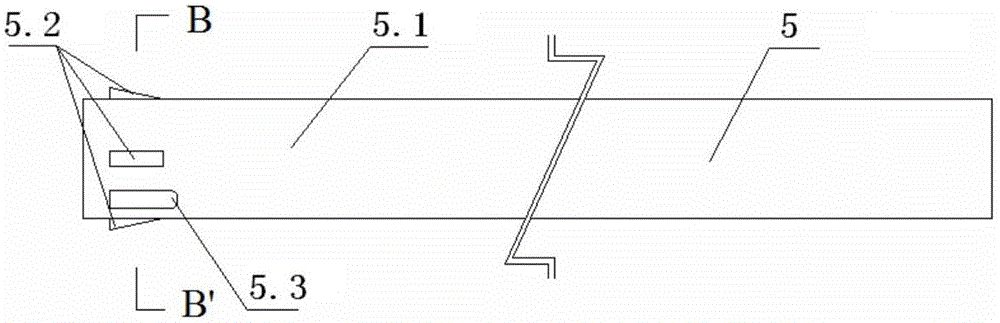

[0024] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

[0025] The broaching anti-rockburst bolt shown in the figure includes an observation pole 1, an anchor nut 2 and an anti-rockburst device 3, wherein the anti-rockburst device 3 includes a casing 4 and a broaching body 5, and the outer wall of the casing 4 The left end is connected with the anchor nut 2, and the right end of the sleeve pipe 4 is threadedly connected with a water stop nut 6, and the joint between the water stop nut 6 and the sleeve pipe 4 is provided with a water stop rubber ring 6.1, so as not to penetrate into the sleeve pipe 4 and corrode the sleeve pipe 4. Inside the casing 4, from left to right, there are threaded section 4.1, tapered broach placement section 4.2, and cutting guide section 4.3. The threaded section 4.1 is connected with a closed bolt 7, and a round hole is reserved in the center of the closed bolt 7 , it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com