Three-blocking two-segment type grouting sealing hole pressure measuring structure and construction method thereof

A two-stage pressure measurement technology, which is applied in measurement, earthwork drilling, sealing/package, etc., can solve problems such as insufficient hole wall sealing, long solidification time, and air leakage, so as to improve the possibility and practicability Strong and safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

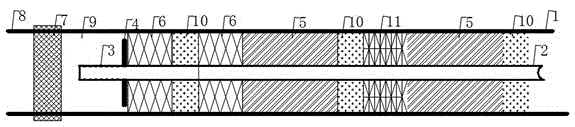

[0029] its implementation method Including the following steps: Step 1: Process a small hole with a diameter of 1cm every 10cm at the front end of the piezometric steel pipe (2) 2m as the sieve section (3), and connect the circular gear at the end of the sieve section (3) disk(4);

[0030] Step 2: First spirally wind the cotton yarn behind the gear disc (4) to form a spirally wound cotton yarn section (6), then tie the bagged marisan directly to the pressure measuring tube (2), and use local materials to fill the cement Wrap the bag around the Malisan to prevent the Malisan bag from being damaged when sending the pressure measuring tube, and then wrap a piece of cotton yarn around the Malisan to form a spirally wound cotton yarn section (6); then remove the stop valve on the Malisan bag , mix the two parts inside it evenly, and send it into the grouting sealing hole pressure measuring structure (1);

[0031] Step 3: After waiting for about 20 minutes, inject cement mortar c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com