Method for inhibiting corrosion of oil producing well tube inner wall

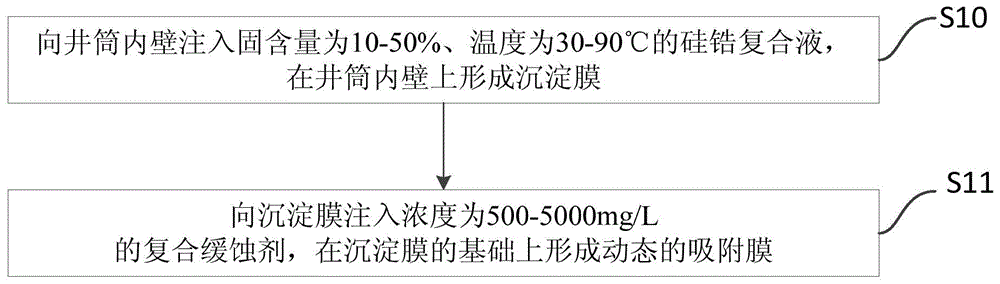

A technology for the inner wall of barrels and oil production wells, which is applied in the field of corrosion control. It can solve the problems of short maintenance time of corrosion inhibitors and achieve strong oxygen resistance, good corrosion resistance and mechanical properties, and good effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The production process of the silicon-zirconium composite solution is as follows: dissolve 20g of epoxy siloxane in 200g of ethanol, add 200g of water to the solution, adjust the pH value of the mixed solution to 4-5, and then heat the mixed solution to 20 Hydrolyze at -80°C for 1-6 hours, cool to room temperature, and age for 24 hours to form a silane solution; the heating temperature is preferably 40-70°C, most preferably 60°C, and the hydrolysis time is preferably 2 hours.

[0043] Dissolve 10g of ammonium fluorozirconate in 600ml of water; add 1g of sodium molybdate, 0.5g of boric acid, 0.5g of citric acid and 1g of diethanolamine in sequence to the ammonium fluorozirconate solution.

[0044] Add the ammonium fluozirconate solution into the epoxy siloxane solution, adjust the pH value to 5-6, and stir for 1 hour to obtain a silicon-zirconium composite solution. The solid content of the silicon-zirconium composite solution is preferably 20-40%, and the optimum It is ...

Embodiment 2

[0046] The production process of the silicon-zirconium composite liquid is as follows: dissolve 20g of vinyl siloxane in 200g of ethanol, add 200g of water to the solution, adjust the pH value of the mixed solution to 4-5, and then heat the mixed solution to 20- Hydrolyze at 80°C for 1-6 hours, cool to room temperature, and age for 24 hours to form a silane solution; the heating temperature is preferably 40-70°C, most preferably 60°C, and the hydrolysis time is preferably 2 hours.

[0047]Dissolve 10g of ammonium fluorozirconate in 600ml of water; add 1g of sodium molybdate, 0.5g of boric acid, 0.5g of citric acid and 1g of diethanolamine in sequence to the ammonium fluorozirconate solution.

[0048] Add the ammonium fluorozirconate solution into the vinyl siloxane solution, adjust the pH value to 5-6, and stir for 1 hour to obtain a silicon-zirconium composite solution. The solid content of the silicon-zirconium composite solution is preferably 20-40%, most preferably The use...

Embodiment 3

[0050] Composite corrosion inhibitor is composed of two kinds of corrosion inhibitors (the compounding ratio of corrosion inhibitor 1 and corrosion inhibitor 2 is 1:1, 1:2 or 1:3).

[0051] The production process of corrosion inhibitor 1 is:

[0052] Add 3 kg of alkyl alkenoic acid into the reactor, start stirring and raise the temperature of the reactor to 70°C, slowly add 0.5 kg of polyethylene polyamine into the reactor, then pass nitrogen into the reactor, and slowly raise the temperature of the reactor React at a constant temperature of 120°C for 1 hour, then slowly raise the temperature of the reactor to 180°C for 2 hours, then raise the temperature of the reactor to 230°C for 4 hours, then lower the temperature of the reactor to below 100°C, slowly pour into the reactor Add 0.5 kg of sulfur-based compound, and finally raise the temperature of the reactor to 130°C for 4 hours of constant temperature reaction to obtain corrosion inhibitor 1.

[0053] The molecular struct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com