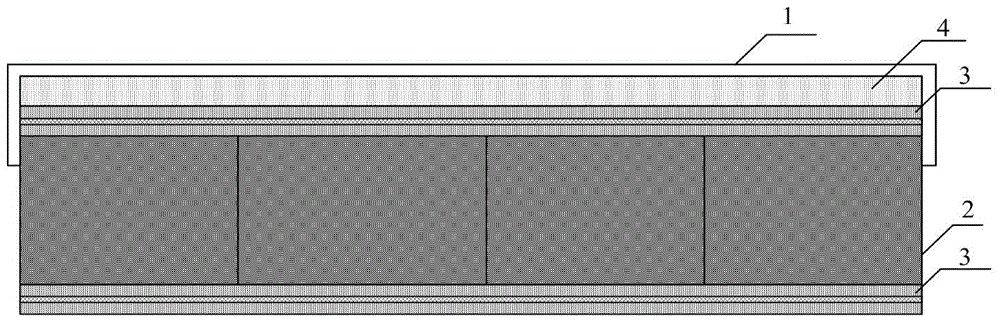

Grade-A fireproof metal decoration heat insulation plate and production process thereof

A technology of metal decoration and production technology, which is applied in the direction of lamination devices, layered products, and layered products of hydraulic substances. Improve plate utilization, excellent fire prevention effect, good bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0030] It should be understood that terms such as "having", "comprising" and "including" as used herein do not entail the presence or addition of one or more other elements or combinations thereof.

[0031] A realization form of the production process of a class A fireproof metal decorative insulation board according to the present invention, which includes the following steps:

[0032] Step 1: Splicing multiple thermal insulation core materials with the first adhesive to obtain a standard board, the thermal insulation core material is foamed ceramics or foamed glass, and its function is to provide two kinds of fireproof A-level thermal insulation materials, with Light in weight and low in cost; and the specifications and sizes of the insulation materials can be guaranteed af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com