A top membrane water retaining method for underwater maintenance of channel lining

A lining and channel technology, which is applied in water conservancy projects, artificial waterways, sea area engineering, etc., can solve the problems of not being able to provide the base for channel section operations, destroying the lining of occupied areas, and high cost, and achieve simple structure, convenient transition in water, Good water stop effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

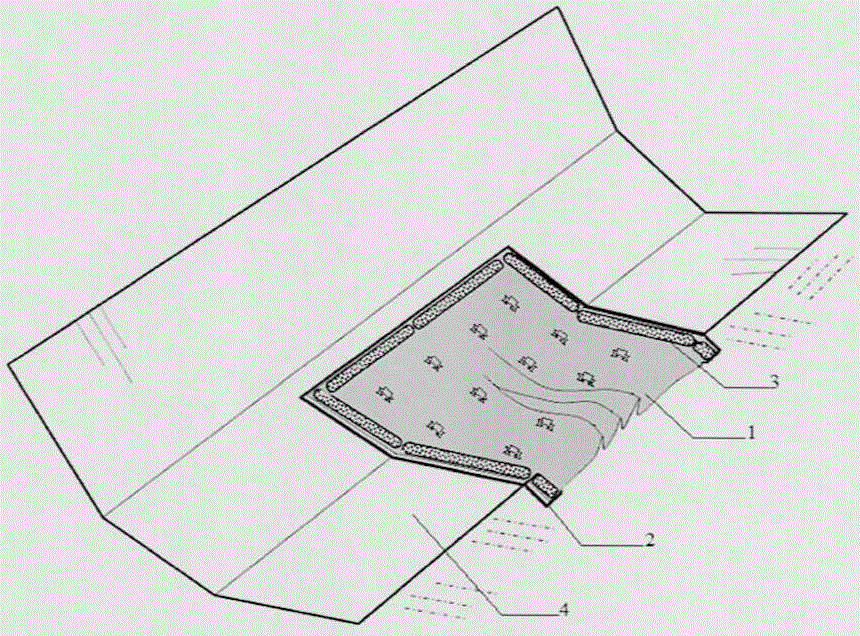

[0011] Such as figure 1 As shown, the present invention is a top membrane water-retaining method for underwater maintenance of channel lining, which includes the following construction technology: the flexible waterproof membrane 1 is made of nylon-impregnated canvas with increased density, and can be heavy by its own weight. At the bottom of the water, hangers are distributed on the water surface for lifting on the water surface; on the edge of the flexible waterproof membrane 1 that needs to be sealed, a sealing layer 2 is installed on the back surface, and an assembly weight 3 is added on the water surface; the flexible waterproof membrane 1 sinks into the water with the back surface facing down , pasted on the surface of the channel lining 4 in the area to be overhauled, and the unsealed edge of the flexible waterproof membrane 1 is exposed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com