Aeromonas sp. YQ and its application in enzymatic preparation of L-citrulline

A technology of Aeromonas and citrulline, applied in the direction of bacteria, microorganism-based methods, biochemical equipment and methods, etc., can solve the problems that there is no Aeromonas to produce L-citrulline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

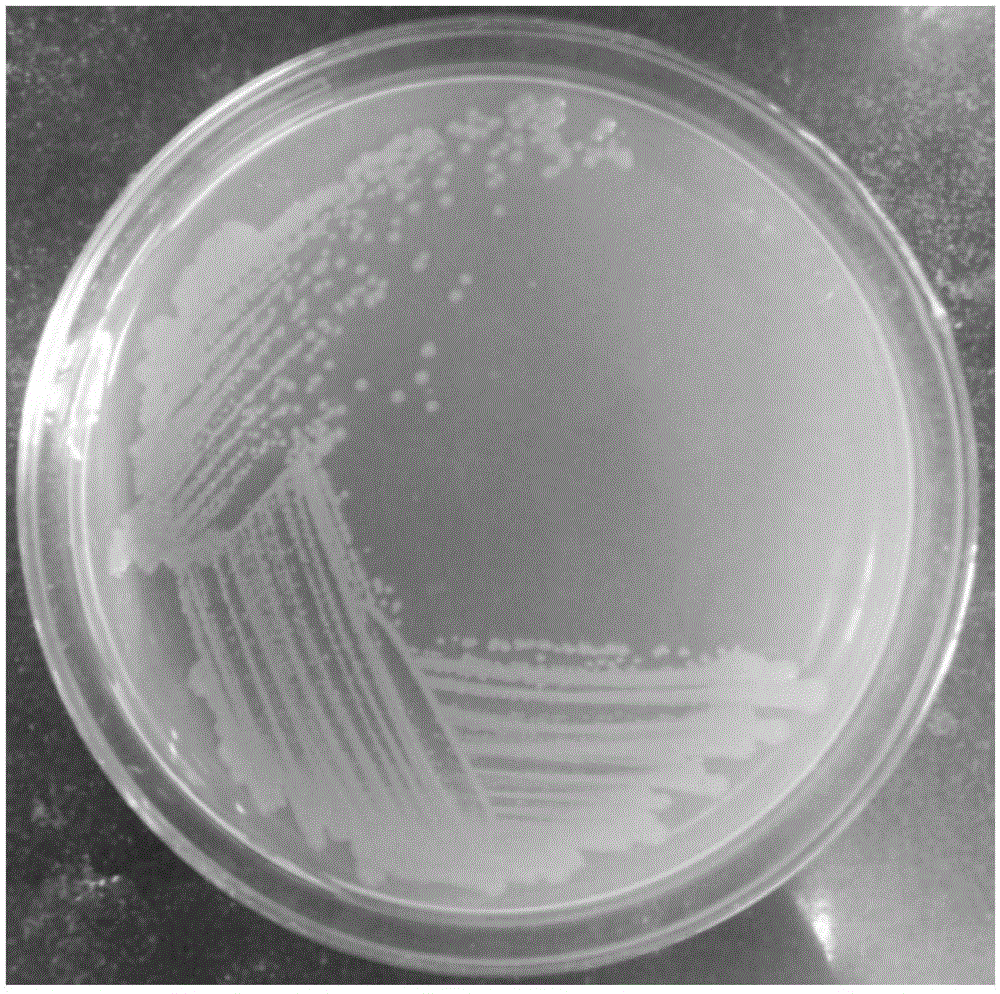

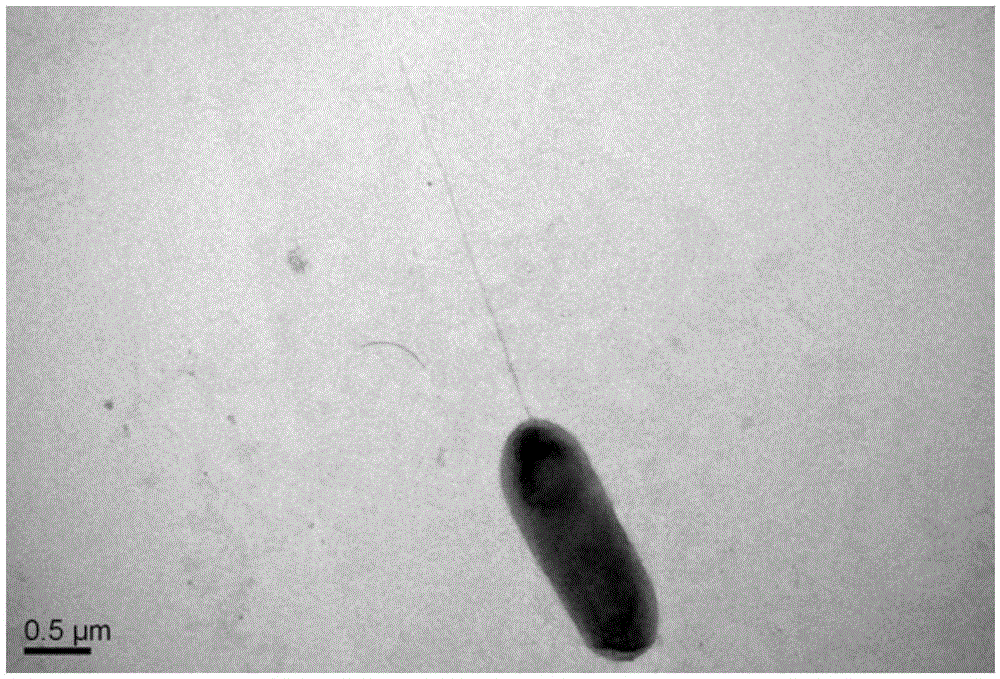

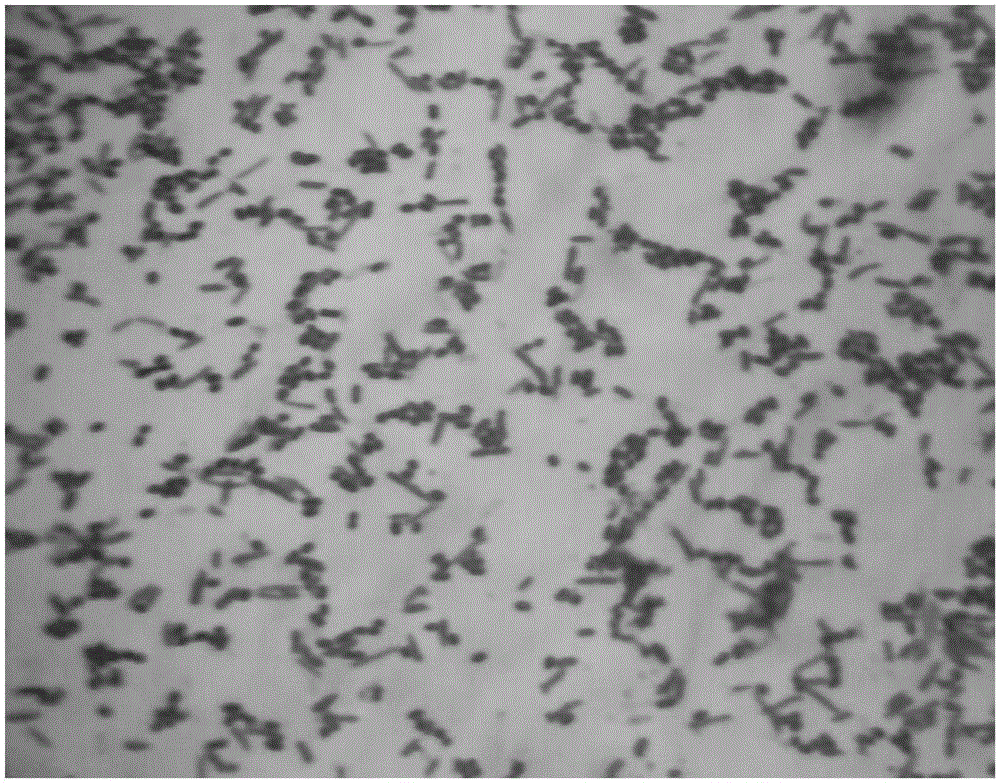

[0019] Example 1: Screening of L-citrulline strains produced by enzymatic transformation

[0020] (1) Strain screening

[0021] Soil samples were collected from watermelon greenhouses in Gouzhuang, Hangzhou City, Zhejiang Province, made suspensions with normal saline, and diluted with normal saline gradients, spread on screening medium plates, placed in an incubator, and incubated at 37°C for 24 hours to produce a red color The strain with larger color change circle is the object of preliminary screening. Inoculate the above strains into 100ml of fermentation culture, culture at 37°C, 180r / min for 24h, collect the bacteria by centrifugation, transfer to 60ml of acetic acid buffer solution with a final concentration of 100g / LL-arginine at pH 6, and place at 37°C Shaker, 180r / min transformation 1d. The concentration of L-citrulline in the transformation solution was measured by HPLC, and the ability of the bacteria to transform substrate L-arginine to produce L-citrulline was ...

Embodiment 2

[0027] Activation and fermentation of embodiment 2 bacterial strains

[0028] Aeromonas YQ was inoculated into the slant medium and cultured at 37°C for 24 hours to obtain slant cells. Inoculate one loop of slant bacteria into a 250 mL Erlenmeyer flask filled with 50 mL of seed medium, and cultivate at 37° C. for 24 hours at 180 rpm to obtain seed liquid. Then inoculate the seed liquid in 100ml fermentation medium with an inoculation amount of 4% volume concentration, culture at 37°C and 180r / min for 24h, centrifuge the fermentation liquid at 6000rpm for 10min, collect the bacteria and wash them with sterilized physiological saline for 1-2 times , to obtain wet cells.

[0029] Slant medium composition: peptone 10g / L, beef extract 5g / L, NaCl 3g / L, KH 2 PO 4 2g / L, the solvent is deionized water, agar 20g / L, pH=7.4.

[0030] Seed medium composition: peptone 10g / L, beef extract 5g / L, NaCl 3g / L, KH 2 PO 4 2g / L, the solvent is deionized water, pH=7.4.

[0031] Fermentation me...

Embodiment 3

[0032] Example 3: Preparation of Aeromonas YQ transformation liquid and derivatization of L-citrulline

[0033]Add 0.621 g of the wet bacteria prepared in Example 2 into 60 ml of acetic acid buffer solution with a final concentration of 100 g / LL-arginine at pH = 6, pipette repeatedly to evenly fill the liquid with a volume of 60 mL, place it at 37°C, and start at 180 r / min conversion reaction. After the transformation reaction for 3 days, take the transformation solution and centrifuge it at 10000r / min for 5min every 24h, dilute the supernatant 30 times with distilled water, take 1mL and put it into a 10mL brown volumetric flask (because the derivative is easy to decompose when exposed to light), add the prepared pH Na of 9 2 CO 3 -NaHCO 3 Add 1 mL of buffer solution, then add 1 mL of 2,4-dinitrofluorophenylacetonitrile solution with a volume concentration of 1.5%, shake well, heat in a water bath at 60°C for 1 h, and use K 2 HPO 4 -KH 2 PO 4 Buffer to volume. The deri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com