Derusting antirust colored heavy-duty single-component primer and production technique thereof

A heavy-duty anti-corrosion, one-component technology, applied in anti-corrosion coatings, coatings, etc., can solve the problems of two-component construction troubles, high VOC content, high processing requirements, etc., and achieve long water resistance and salt spray resistance, paint film strength and hardness The effect of high and low overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A rust-removing and anti-rust colored heavy-duty anti-corrosion single-component primer, comprising the following components in parts by weight:

[0030] 5 parts deionized water

[0031] 1318 steel protective agent 20 parts

[0032] Alcohol ester twelve parts

[0033] 2 parts propylene glycol

[0034] 0.1 parts of 2% xanthan gum

[0035] 3 parts black color paste

[0036] Rhodia DN-6420.3 copies

[0037] H602 emulsion 40 parts

[0038] GEM-03 epoxy resin 3 parts

[0039] Xuanning 165F0.3 copies.

[0040] The production process of the above-mentioned one-component rust-removing, anti-rust, colored and heavy-duty anti-corrosion primer: each raw material component is prepared according to the mass part, then mixed, and stirred and dispersed in a stainless steel reaction kettle, stirred and dispersed for 30 minutes, and the rotation speed is 500-800 revs / min; After all the indicators are tested and passed, after the stirring is completed, the 100-mesh filter is filt...

Embodiment 2

[0042] A rust-removing and anti-rust colored heavy-duty anti-corrosion single-component primer, comprising the following components in parts by weight:

[0043] 20 parts deionized water

[0044] 25 copies of kx-123 steel protective agent

[0045] 8 parts of ethylene glycol butyl ether

[0046] Propylene Glycol 4 parts

[0047] 0.2 parts of polyvinyl alcohol ether

[0048] 10 parts black color paste

[0049] BASF 24101 parts

[0050] H602 emulsion 70 parts

[0051] GEM-03 epoxy resin 5 parts

[0052] Xuanning 165F0.6 copies.

[0053] The production process of the above-mentioned one-component rust-removing, anti-rust, colored and heavy-duty anti-corrosion primer: each raw material component is prepared according to the mass part, then mixed, and stirred and dispersed in a stainless steel reaction kettle, stirred and dispersed for 30 minutes, and the rotation speed is 500-800 revs / min; After all the indicators are tested and passed, after the stirring is completed, the 1...

Embodiment 3

[0055] A rust-removing and anti-rust colored heavy-duty anti-corrosion single-component primer, comprising the following components in parts by weight:

[0056] 12 parts deionized water

[0057] 1318 steel protective agent 22 parts

[0058] 5 parts of propylene glycol methyl ether

[0059] Diethylene glycol 3 parts

[0060] 0.15 parts of 2% xanthan gum

[0061] 6 parts of black color paste

[0062] Rhodia DN-6420.6 copies

[0063] H602 emulsion 45 parts

[0064] GEM-03 epoxy resin 4 parts

[0065] Xuanning 165F0.4 copies.

[0066] The production process of the above-mentioned one-component rust-removing, anti-rust, colored and heavy-duty anti-corrosion primer: each raw material component is prepared according to the mass part, then mixed, and stirred and dispersed in a stainless steel reaction kettle, stirred and dispersed for 30 minutes, and the rotation speed is 500-800 revs / min; After all the indicators are tested and passed, after the stirring is completed, the 100...

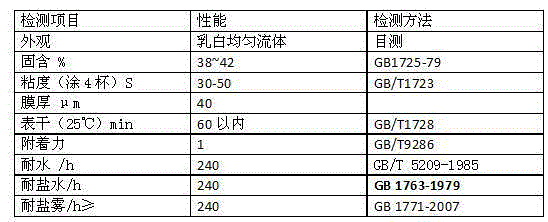

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com