A pressure-resistant polypropylene thermal insulation material and its preparation method and application

A technology of thermal insulation material and polypropylene, applied in the field of pressure-resistant polypropylene thermal insulation material and its preparation, can solve the problems of complex preparation method, unsuitable for large-scale industrial production, etc. The effect of high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

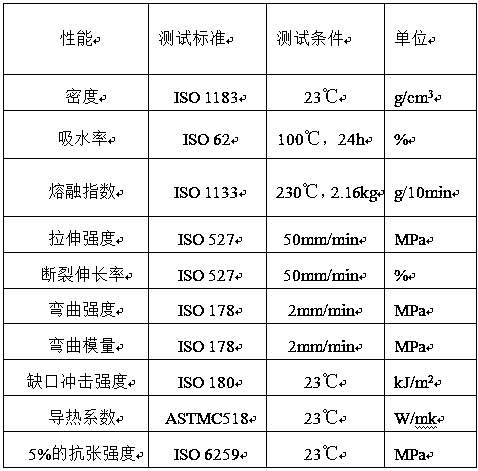

Image

Examples

Embodiment 1-8 and comparative example 1-10

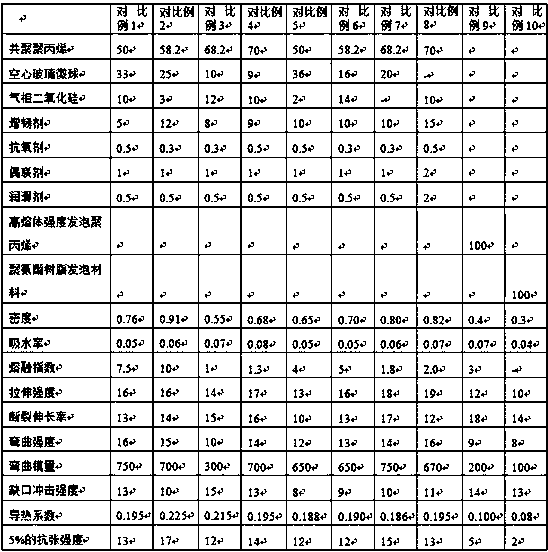

[0052] Examples 1-8 and Comparative Examples 1-10: Preparation of pressure-resistant polypropylene insulation material

[0053] Mix the copolymerized polypropylene and additives weighed according to the ratio in Table 2 in a high mixer to obtain a mixed material; add the above-mentioned mixed material through the main feeding port of the twin-screw extruder; The hollow glass microspheres and fumed silica after weighing according to the proportioning ratio of Table 2 are added through the side feeding of the twin-screw extruder; Compressed polypropylene insulation material; the pressure-resistant polypropylene insulation material is extruded into a thick sheet of 60mm*7mm through a single-screw extruder at a temperature of 200°C, and then the sheet-shaped material is made into a standard-sized spline for processing. Mechanical performance test, the test data are shown in Table 2.

[0054] Table 2 Specific proportions (percentage by weight) and test performance results of Examp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com