Doxofylline compound and medicine composition thereof

A technology of doxofylline and compound, applied in the field of medicine, can solve the problems of reduced active ingredient content, insufficient quality stability, unfavorable clinical drug safety and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The preparation of embodiment 1 doxofylline compound

[0038] At 50-60° C. and a stirring speed of 100-150 rpm, theophylline and 2-bromo-1,3-dioxolane are added to the reactor in a weight ratio of 1:1.2. After adding sodium carbonate as a catalyst and dimethylformamide as a solvent, the temperature starts to rise, and the reaction temperature is kept at 110-115°C. After the reaction was finished, dimethylformamide was recovered by distillation under reduced pressure. Cool the reaction to 20-25°C, filter and rinse with pure water. To the filtered crude product of doxofylline, add about 1.5% of the weight of doxofylline with activated carbon and a small amount of toluene, stir at 150-200 rpm for 30 minutes, filter to remove carbon, and filter the filtrate through a 0.22 μm filter membrane. The toluene was then removed by drying at 95-100°C for 6 hours. The doxofylline is dried to a constant weight in a vacuum tray dryer at 95-100° C., namely the doxofylline dry powder....

Embodiment 2

[0039] The preparation of embodiment 2 doxofylline compound

[0040] At 50-60° C. and a stirring speed of 100-150 rpm, theophylline and 2-bromo-1,3-dioxolane are added to the reactor in a weight ratio of 1:1. After adding sodium carbonate as a catalyst and dimethylformamide as a solvent, the temperature starts to rise, and the reaction temperature is kept at 110-115°C. After the reaction was finished, dimethylformamide was recovered by distillation under reduced pressure. Cool the reaction to 20-25°C, filter and rinse with pure water. To the filtered crude product of doxofylline, add about 1.5% of the weight of doxofylline with activated carbon and a small amount of toluene, stir at 150-200 rpm for 30 minutes, filter to remove carbon, and filter the filtrate through a 0.22 μm filter membrane. The toluene was then removed by drying at 95-100°C for 6 hours. The doxofylline is dried to a constant weight in a vacuum tray dryer at 95-100° C., namely the doxofylline dry powder. ...

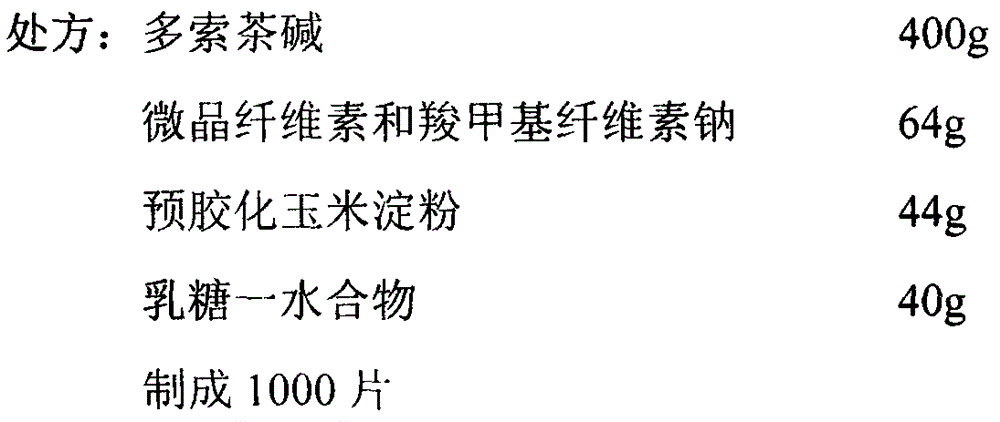

Embodiment 3

[0041] The preparation of embodiment 3 doxofylline injection

[0042] prescription:

[0043] Doxofylline Compound 10g

[0044] Water for injection 1L

[0045] Made of 100

[0046]Dissolve the prescribed amount of doxofylline compound with 80% of the total amount of water for injection at 50°C, adjust the pH to 5.8-6.4 with hydrochloric acid, add water for injection to the full amount, stir evenly, filter with a 0.22 μm filter membrane, and fill in an ampoule , filled with nitrogen, melt-sealed, and sterilized with damp heat at 121° C. for 30 minutes to obtain 10 g: 10 ml doxofylline injection.

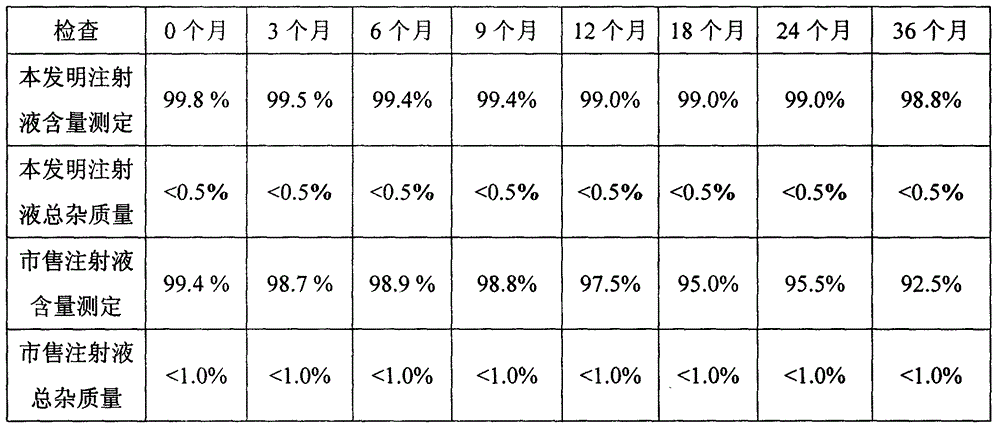

[0047] The doxofylline injection prepared in Example 3 of this experiment and the commercially available doxofylline injection were investigated for long-term stability (25°C±2°C; 60%±5%RH), and the results are shown in Table 1.

[0048] Table 1 Long-term stability investigation table of doxofylline injection

[0049]

[0050] Conclusion: The quality indicators of doxofylline i...

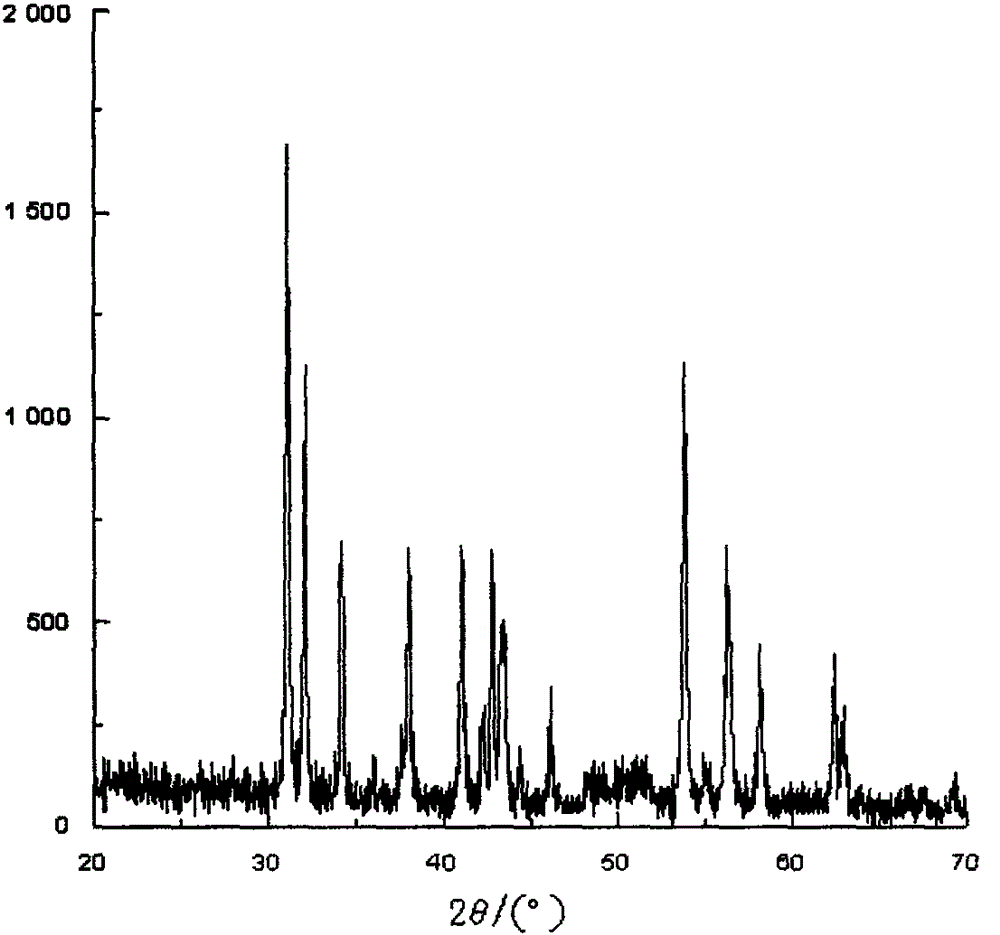

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com