A pyrolysis oil, gas and water synchronous condensation and oil and water separation and recovery system and method

A technology for pyrolysis of oil and gas, oil-water separation, applied in separation methods, liquid separation, dispersed particle separation, etc., can solve problems such as blockage of pipelines, and achieve the effect of saving disposal costs, easy operation, and avoiding the use of chemicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

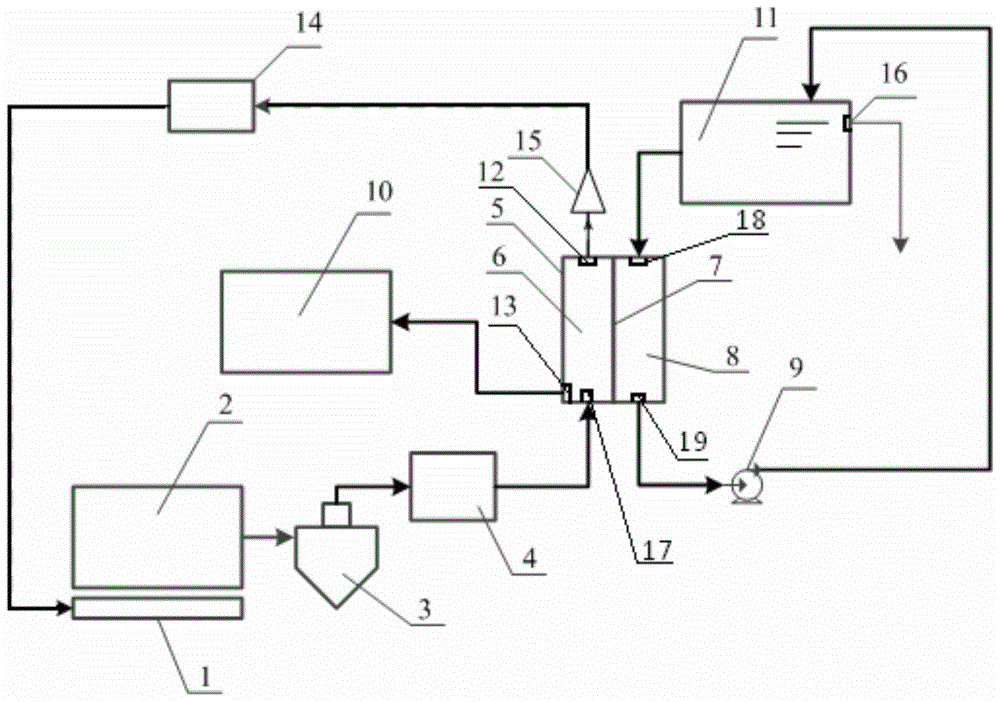

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

[0026] Such as figure 1 As shown, the pyrolysis oil-gas-water synchronous condensation and oil-water separation and recovery system of the present invention includes a heating furnace 1, a pyrolysis reactor 2 arranged on the heating furnace 1, and a cyclone connected to the outlet of the pyrolysis reactor 2 Separator 3, the gas outlet of said cyclone separator 3 is connected with oil-gas-water synchronous condensation separator 5 through oil-gas compressor 4, and said oil-gas-water synchronous condensation separator 5 is composed of oil-gas-water chamber 6, circulating cooling water chamber 8, The oil-water separation membrane 7 arranged between the oil-gas-water chamber 6 and the circulating cooling water chamber 8 is composed of an oil-water separation membrane 7 made of one of oil-water separation fiber membranes or ceramic membranes; the upper part of the oil-gas-w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com