Rapid synthesis technology for poly-ferric sulfate aluminum

A technology of polyferric aluminum sulfate and polyferric aluminum sulfate, which is applied in the fields of ferric sulfate, chemical recovery, flocculation/sedimentation water/sewage treatment, etc., can solve problems such as nitrite residue, achieve elimination of nitrite, and good development prospects , the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

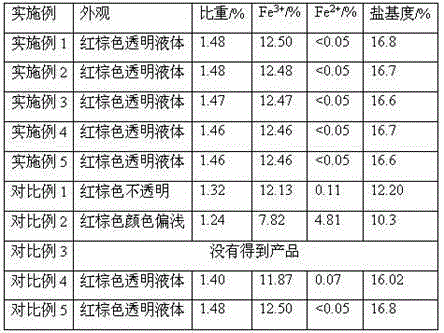

Examples

Embodiment 1

[0023] 1) Add 54% of ferrous sulfate heptahydrate, 2.9% of soluble aluminum hydroxide, 9.6% of sulfuric acid, and 33.5% of water into the reactor according to the mass percentage, and the acid solubility of soluble aluminum hydroxide is 94.5%;

[0024] 2) Add 1.0‰ manganese dioxide with the mass of ferrous sulfate heptahydrate to the reactor through the metering screw conveyor as a catalyst, and spray liquid oxygen into the reactor at the same time to start the oxidation reaction, and the initial pressure of liquid oxygen injection at the beginning of the oxidation reaction At 0.34MPa, adjust the liquid oxygen injection pressure to 0.25MPa after 10 minutes of reaction, and control the reaction temperature at 50°C during the process;

[0025] 3) The oxidation reaction inside the reactor spontaneously proceeds with hydrolysis and polymerization. After the reaction is carried out for 30 minutes, the material is spray-dried to obtain polyferric aluminum sulfate, and the manganese d...

Embodiment 2

[0027] 1) According to mass percentage, 56% of ferrous sulfate heptahydrate, 1% of soluble aluminum hydroxide, 9.5% of sulfuric acid, and 33.5% of water are added to the reactor, and the acid solubility of soluble aluminum hydroxide is 94.5%;

[0028] 2) Add 1.2‰ manganese dioxide with the mass of ferrous sulfate heptahydrate to the reactor through the metering screw conveyor as a catalyst, and spray liquid oxygen into the reactor at the same time to start the oxidation reaction, and the initial pressure of liquid oxygen injection at the beginning of the oxidation reaction At 0.35MPa, adjust the liquid oxygen injection pressure to 0.26MPa after 10 minutes of reaction, and control the reaction temperature at 48°C during the process;

[0029] 3) The oxidation reaction inside the reactor spontaneously proceeds with hydrolysis and polymerization. After 33 minutes of reaction, the material is spray-dried to obtain polyferric aluminum sulfate, and the manganese dioxide catalyst is re...

Embodiment 3

[0031] 1) According to mass percentage, 51.9% of ferrous sulfate heptahydrate, 5% of soluble aluminum hydroxide, 9.6% of sulfuric acid, and 33.5% of water are added to the reactor, and the acid solubility of soluble aluminum hydroxide is 94.5%;

[0032] 2) Add 0.9‰ manganese dioxide with the mass of ferrous sulfate heptahydrate to the reactor through the metering screw conveyor as a catalyst, and spray liquid oxygen into the reactor at the same time to start the oxidation reaction, and the initial pressure of liquid oxygen injection at the beginning of the oxidation reaction At 0.32MPa, adjust the liquid oxygen injection pressure to 0.28MPa after 10 minutes of reaction, and control the reaction temperature at 52°C during the process;

[0033]3) The oxidation reaction inside the reactor spontaneously proceeds with hydrolysis and polymerization. After 32 minutes of reaction, the material is spray-dried to obtain polyferric aluminum sulfate, and the manganese dioxide catalyst is r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com