Strip cutter for polytetrafluoroethylene sealing tape for thread sealing

A polytetrafluoroethylene and thread sealing technology, applied in the field of fluoroplastics production, can solve the problems of raw material belt pulling, uneven width of the raw material belt, affecting use, etc., and achieve the effect of preventing pulling deformation and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

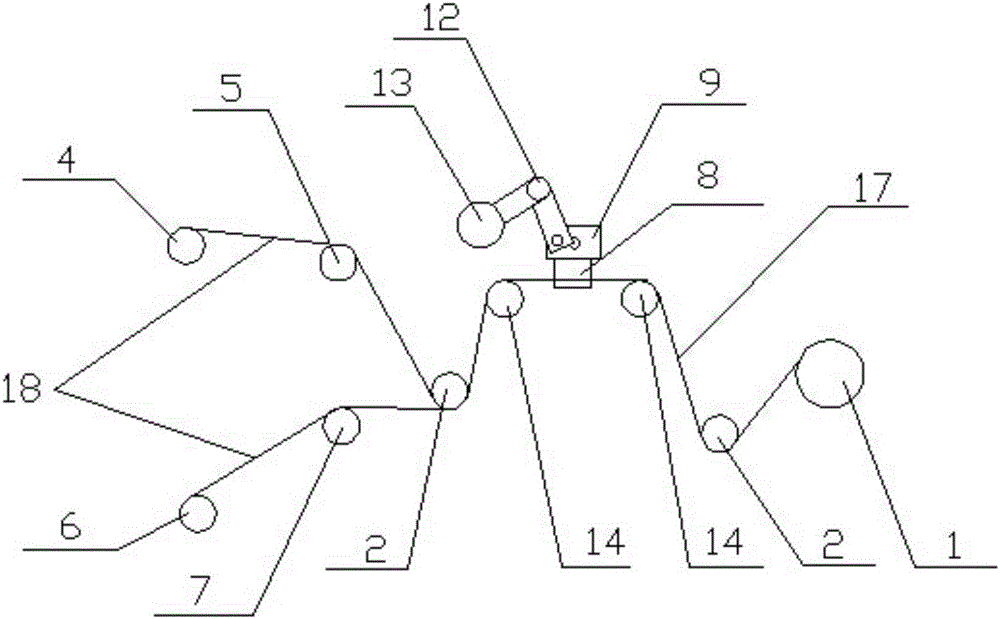

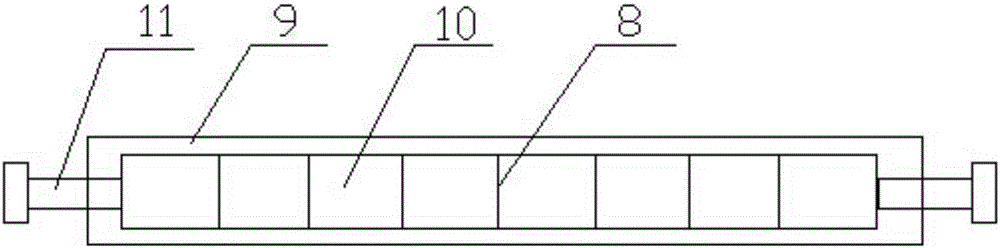

[0024] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0025] Such as Figure 1~6 As shown, the PTFE raw tape cutting machine for thread sealing includes a bracket, a motor, a reducer, an uncoiling device 1, a tension roller 2, a slitting device and a winding device, and the slitting device is located in the uncoiling device 1 and the winding device, the unwinding device 1, the tension roller 2, the cutting device and the winding device are all arranged on the bracket, the tension roller 2 is arranged on both sides of the cutting device, and the winding device includes a place for placing the winding drum 3 The upper winding device and the lower winding device, the raw material tape passing through the cutting device is wound from the upper winding device and the lower winding device respectively, the motor drives the winding device to rotate, and the reducer is connected between the motor and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com