Automatic dried tofu collecting device

An automatic collection and dried tofu technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve problems such as labor-intensive, difficult to cut evenly, time-consuming and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

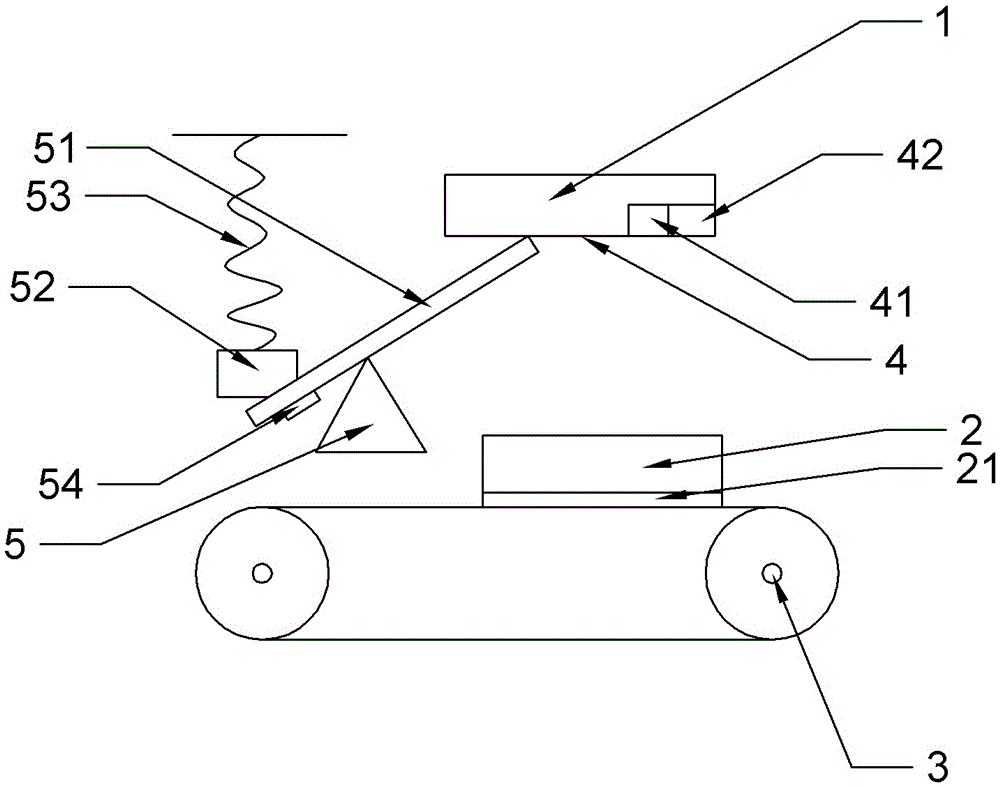

[0015] Such as figure 1 As shown, the dried tofu automatic collection device includes a collection box body 1, a storage box 2 and a transmission mechanism 3. The collection box body 1 is a box with walls around it without an upper cover. The bottom of the box is hinged with a movable flap 4. The collection box Body 1 is a wooden material. The storage box 2 is located directly below the collection box body 1, and the storage box 2 is placed on the transmission mechanism 3. The volume of the storage box 2 is the same as that of the collection box body 1, and the material is also the same as that of the collection box body 1. For cushioning, a rubber layer 21 is provided at the bottom of the housing box 2 . The transmission mechanism 3 is a belt transmission, including a driving wheel, a driven wheel and a belt. The belt transmission noise is small and the transmission is relatively stable. Wherein the area of the movable flap 4 is greater than the bottom area of the colle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com