Method for operating hydraulic brake equipment

A technology of hydraulic braking and equipment, applied in the direction of brakes, brake transmission devices, braking action starting devices, etc., can solve problems such as noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

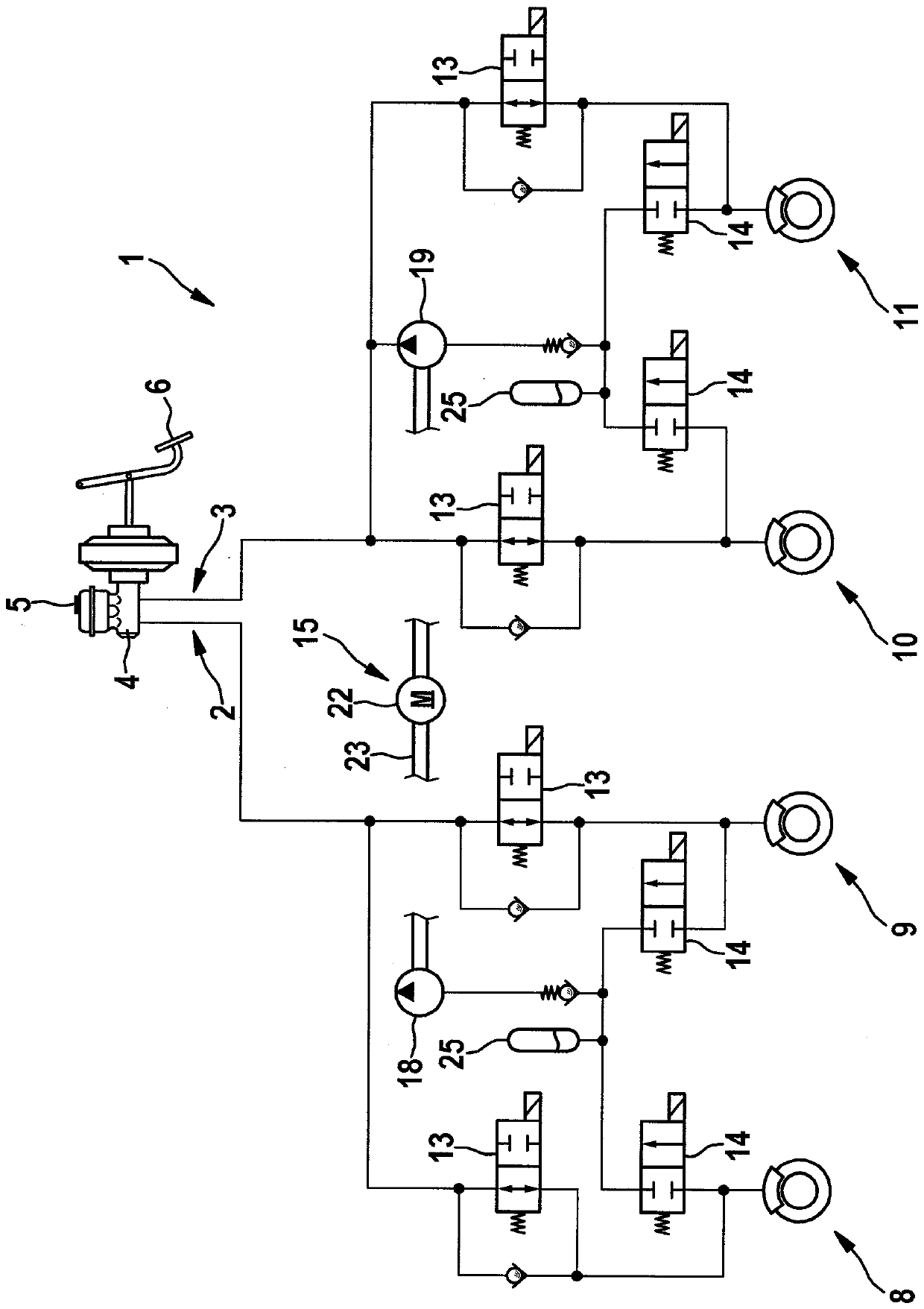

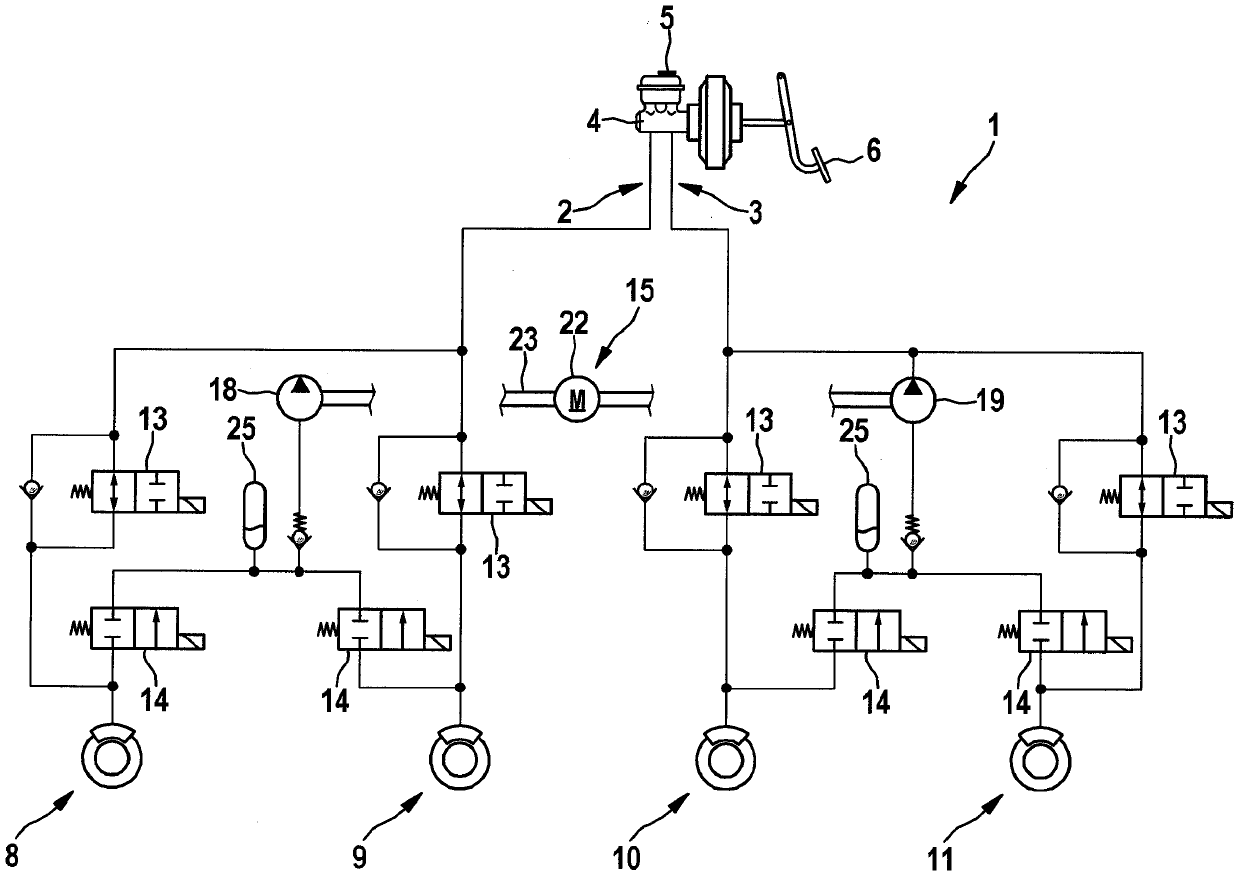

[0018] in accordance with figure 1 The hydraulic brake system shown in the hydraulic circuit diagram in the brake system 1 has a first brake circuit 2 and a second brake circuit 3 for each of the two wheel brake units 8, 9, 10, 11 Supply hydraulic brake fluid. The brake circuit assignment is, for example, diagonal, so that each brake circuit 2 , 3 is provided with a wheel brake unit on a front wheel and a rear wheel.

[0019] The two brake circuits 2 , 3 are connected to a common master brake cylinder 4 , which is supplied with brake fluid via a brake fluid reservoir 5 . Master brake cylinder 4 is actuated by the driver via brake pedal 6 , the pedal travel applied by the driver can be measured by a pedal travel sensor.

[0020] In each brake circuit 2, 3 there is an inlet valve 13 which is open without current (normally open) and is assigned a non-return valve which can be connected from the wheel brake unit in the direction of the master brake cylinder Upstream.

[0021] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com