3d printing assembly line

A 3D printing and assembly line technology, applied in processing and manufacturing, manufacturing auxiliary devices, processing data acquisition/processing, etc., can solve the problems of long time consumption, immature production mode, high manufacturing cost, etc., to extend the production cycle, reduce printing costs and Time and the effect of increasing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

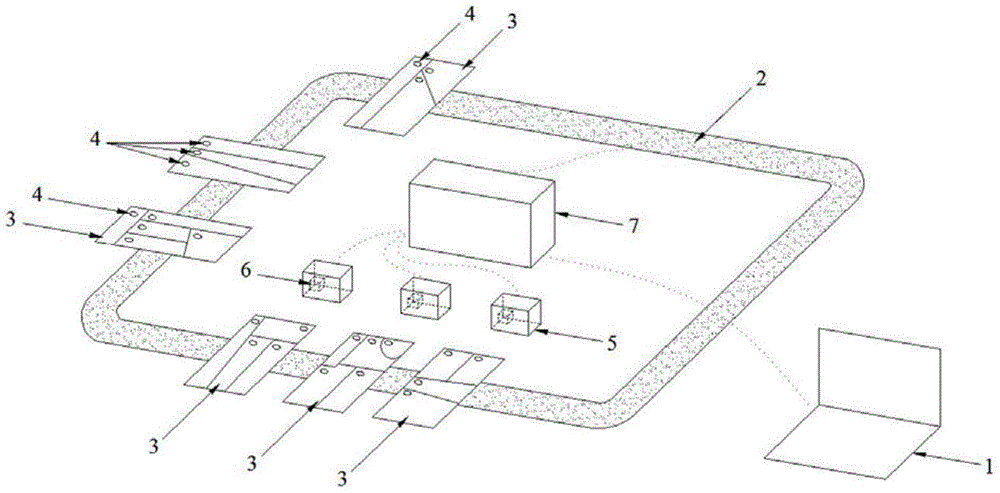

[0033] refer to figure 1 , the 3D printing assembly line of the present invention, which includes: a product delivery device 2 , a printer 5 , a control device 7 and a computer 1 .

[0034] The structure and function of each component are introduced in detail below.

[0035] 1. Product transfer device

[0036] The product transfer device 2 is used to transfer the products that have completed the printing task of one link to the next link for printing, which can ensure the orderly progress of the entire production process. In this embodiment, the guide rail of the product delivery device 2 is in the shape of a ring.

[0037] Several formwork platforms 3 are installed on the product transfer device 2, and an identification code 4 is pasted on each formwork platform 3. The identification code 4 includes the following information: the mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com