Slotting device for inner wall of spun yarn ring spinning bobbin

A technology of ring spinning and tube inner wall, applied in metal processing and other directions, can solve the problems of high cost, complicated installation, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

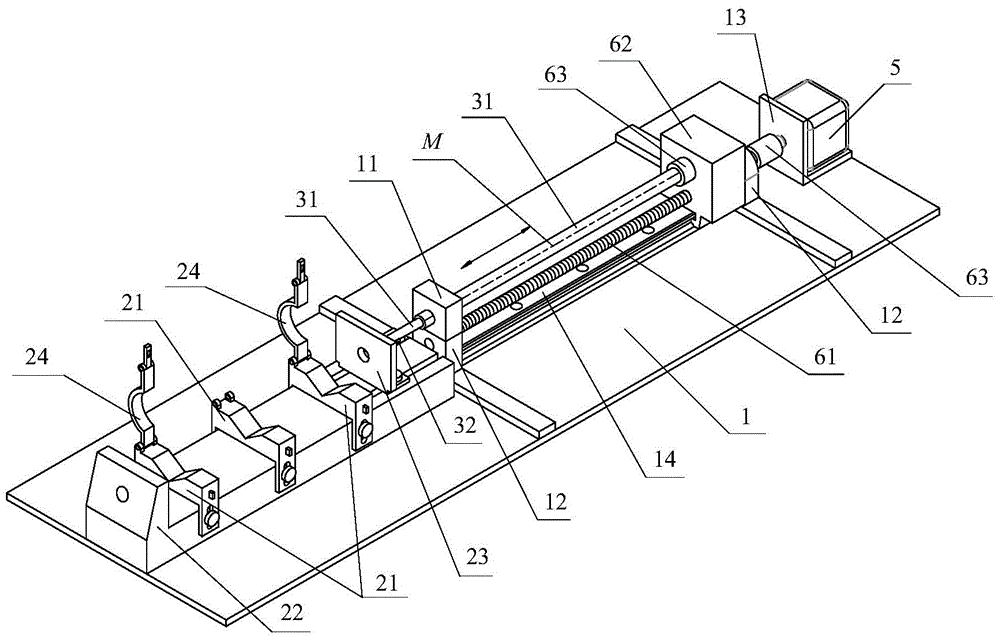

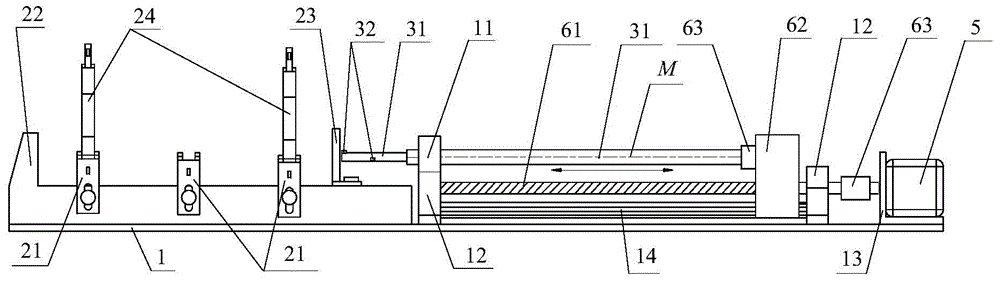

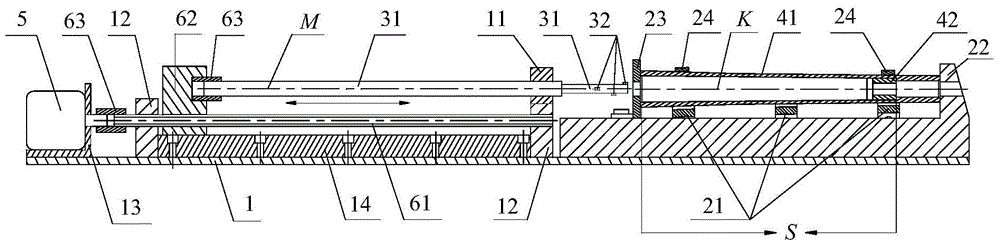

[0038] The specific structure, working principle and working process of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0039] An embodiment of the device for slotting the inner wall of the spun yarn ring spinning tube designed by the present invention, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 and Figure 11 As shown, it includes a base 1, bobbin positioning assembly, cutter bar 31, motor 5, transmission mechanism and at least one cutter 32; the base 1 is provided with a chute 11; the cutter 32 is fixed on the cutter bar 31 , the knife 32 protrudes outward from the knife bar 31; the knife bar 31 is slidably embedded in the chute 11, the center line of the knife bar 31 is set as a straight line M, and the straight line M is consistent with the sliding direction of the knife bar; the bobbin The positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com