Bored cast-in-place pile casing and using method thereof

A technology of bored cast-in-place piles and casings, which is applied to sheet pile walls, buildings, and foundation structure engineering, and can solve problems such as improper concrete pouring measures, difficulty in pulling out casings, and difficulty in ensuring the strength of pile top concrete. The effect of reducing the construction cost and avoiding the secondary transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

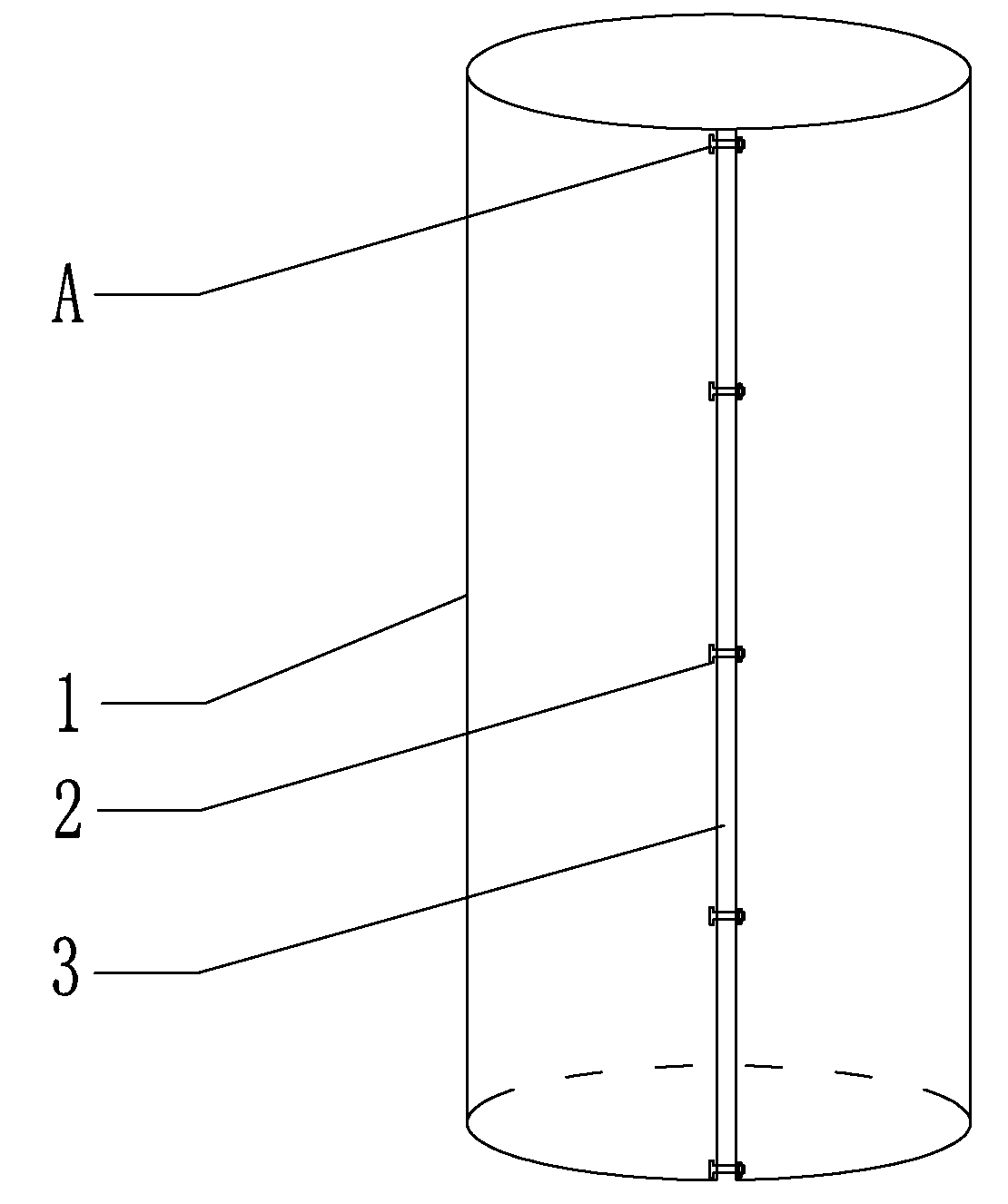

[0032] The bored pile casing of the present invention includes a cylindrical tubular casing, and a pair of lifting lugs, a cutting seam and several buckles are oppositely arranged on both sides of one end of the casing. see now figure 1 , figure 1 It is a schematic diagram of the casing structure of the embodiment of the present invention, figure 2 for figure 1 The detailed drawing of A. As shown in the figure, the casing (1) is rolled from a steel plate with a wall thickness of 8mm, and its inner diameter is 620mm, which is 100mm larger than the diameter of the pile body; the length of the casing is 1.3m;

[0033] The cutting seam (3) is arranged on the side wall of the casing, and is a full-length incision cut along the height direction through both ends of the casing, and the width of the cutting seam (3) is 5mm;

[0034] The several buckles (2) are respectively arranged at the upper and lower ends of the cutting seam (3), and are respectively arranged between the uppe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com