Free state simulating clamping method for bowl-shaped thin-wall ring-shaped part

A ring-shaped part and thin-walled technology, which is applied in the field of imitating free state clamping of bowl-shaped thin-walled ring parts, can solve problems such as clamping deformation and positioning, achieve the effect of eliminating installation tightening deformation and improving processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Describe the present invention below in conjunction with specific embodiment:

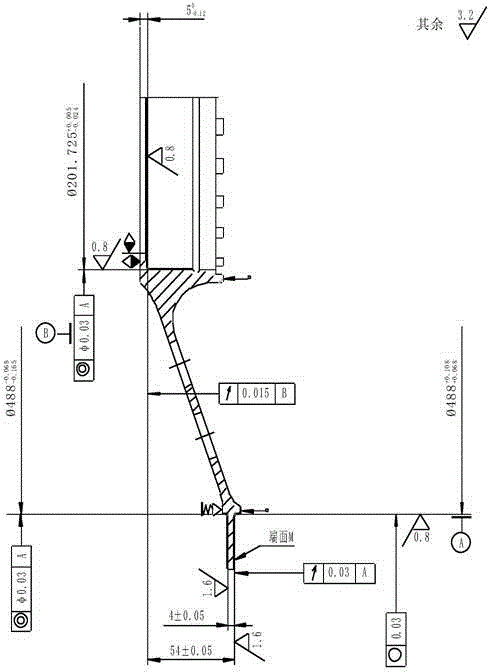

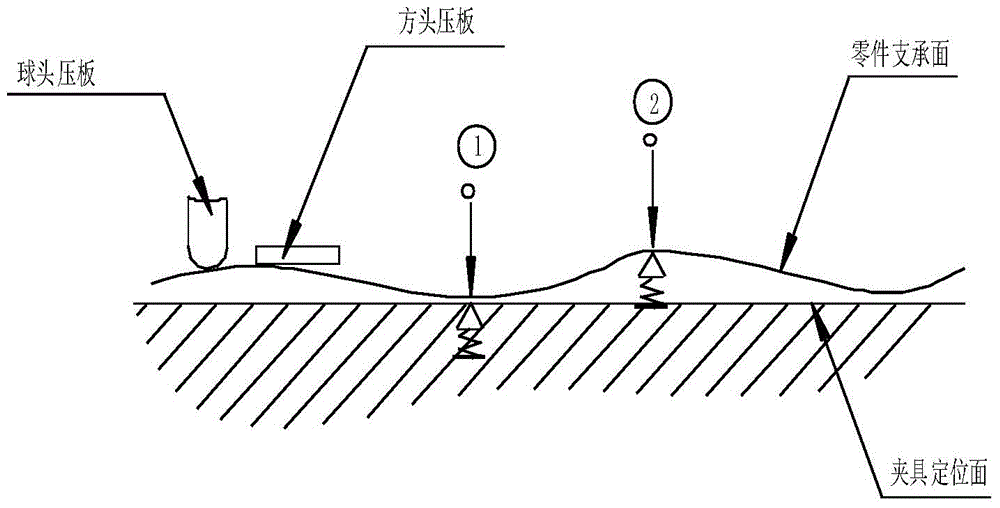

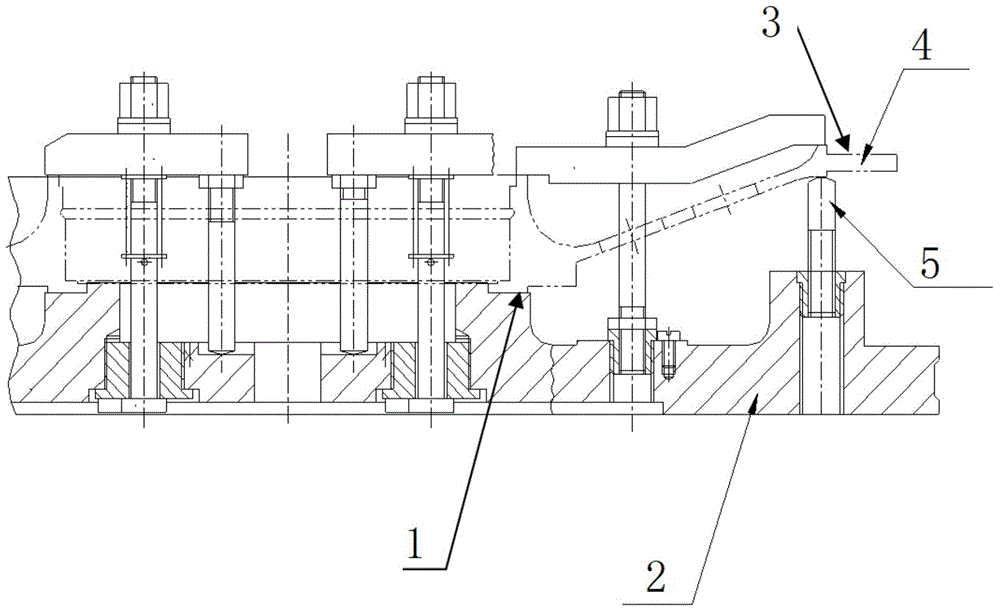

[0022] Such as figure 1 As shown, the bowl-shaped part has a long and thin bowl wall, the inner circle and the adjacent end surface, the outer circle and the adjacent end surface, all have high dimensional accuracy requirements, and at the same time, there is a high degree of precision between the inner shape and the outer shape. The position degree relationship is required, and it is required to be detected in a free state. Due to the high dimensional accuracy of the parts and the poor repeatability of the secondary clamping of thin-walled parts, it is determined that the inner shape of the part must be clamped once and processed at the same time, and the parts must not be deformed during clamping and processing. However, it needs to be pressed during the processing of parts, and there will be deformation when there is a pressing force, especially for thin-walled parts with relatively weak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com