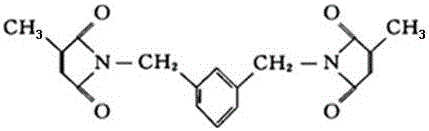

Granulation method and granulation system of 1,3-bis(citraconimidemethyl)benzene

A technology of citraconimide methylation and granulation, applied in the direction of granulating raw materials, chemical instruments and methods, organic chemistry, etc., can solve the problems of short granulation time, long extrusion granulation time, and poor appearance It can reduce the workload, speed up the granulation speed, and achieve the effect of good market prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

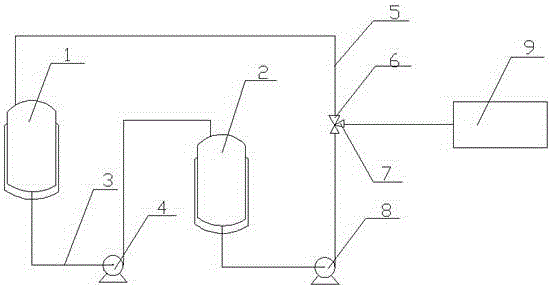

[0041] use figure 1The continuous granulation system shown is for continuous granulation of 1,3-bis(citraconimidemethyl)benzene. The continuous granulation system includes kettle 1 and kettle 2, and the bottom of kettle 1 and kettle 2 are equipped with outlet Material valve, the bottom of kettle 1 is connected with the upper part of kettle 2 through the feeding pipe, and pump 1 is installed on the feeding pipe, and pump 1 sends the material from kettle 1 to kettle 2; the bottom of kettle 2 is connected with the upper part of kettle 1 through the return pipe The return pipe is provided with a return valve and a granulation valve. The granulation valve is connected with the granulator so that the material flowing out of the kettle 2 enters the granulator for granulation. The return valve controls the flow of the material back into the kettle 1. There is also a pump 2 on the return pipe, and the pump 2 sends the material flowing out of the kettle 2 back to the kettle 1 through th...

Embodiment 2

[0049] Using the same continuous granulation system as in Example 1, 1,3-bis(citraconimidemethyl)benzene is continuously granulated, and the continuous granulation method is as follows:

[0050] (1) The powdery material of 1,3-bis(citraconimidemethyl)benzene is sent to Kettle 1 by a continuous conveying device, and Kettle 1 is heated to a temperature of 80°C and kept at a constant temperature for 1 hour.

[0051] (2) Open the discharge valve at the bottom of kettle 1, pump the material to kettle 2 through pump 1, close the granulation valve, fully open the return valve, and return the material in kettle 2 to kettle 1 through the return pipe through pump 2;

[0052] (3) According to the step (2), the materials are continuously circulated in the kettle 1 and the kettle 2. The kettle 2 adopts a water bath. Continue to circulate between kettle 1 and kettle 2 to keep kettle 2 at 43°C, and at the same time, close the return valve so that the materials flowing into kettle 2 can stay ...

Embodiment 3

[0056] Using the same continuous granulation system as in Example 1, 1,3-bis(citraconimidemethyl)benzene is continuously granulated, and the continuous granulation method is as follows:

[0057] (1) The powdery material of 1,3-bis(citraconimidemethyl)benzene is sent to Kettle 1 by a continuous conveying device, and Kettle 1 is heated to a temperature of 80°C and kept at a constant temperature for 1 hour.

[0058] (2) Open the discharge valve at the bottom of kettle 1, pump the material to kettle 2 through pump 1, close the granulation valve, fully open the return valve, and return the material in kettle 2 to kettle 1 through the return pipe through pump 2;

[0059] (3) According to the step (2), the materials are continuously circulated in the kettle 1 and the kettle 2. The kettle 2 adopts a water bath. Part of the material continues to circulate between the kettle 1 and the kettle 2 to keep the kettle 2 at 45°C. At the same time, the return valve is closed so that the materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com