A tubular valve needle needle bottle valve

A tube type and valve needle technology is applied in the field of tube type valve needle needle bottle valve structure, which can solve the problems of narrow application range, large occupation volume, troublesome use, etc. effect of detox

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

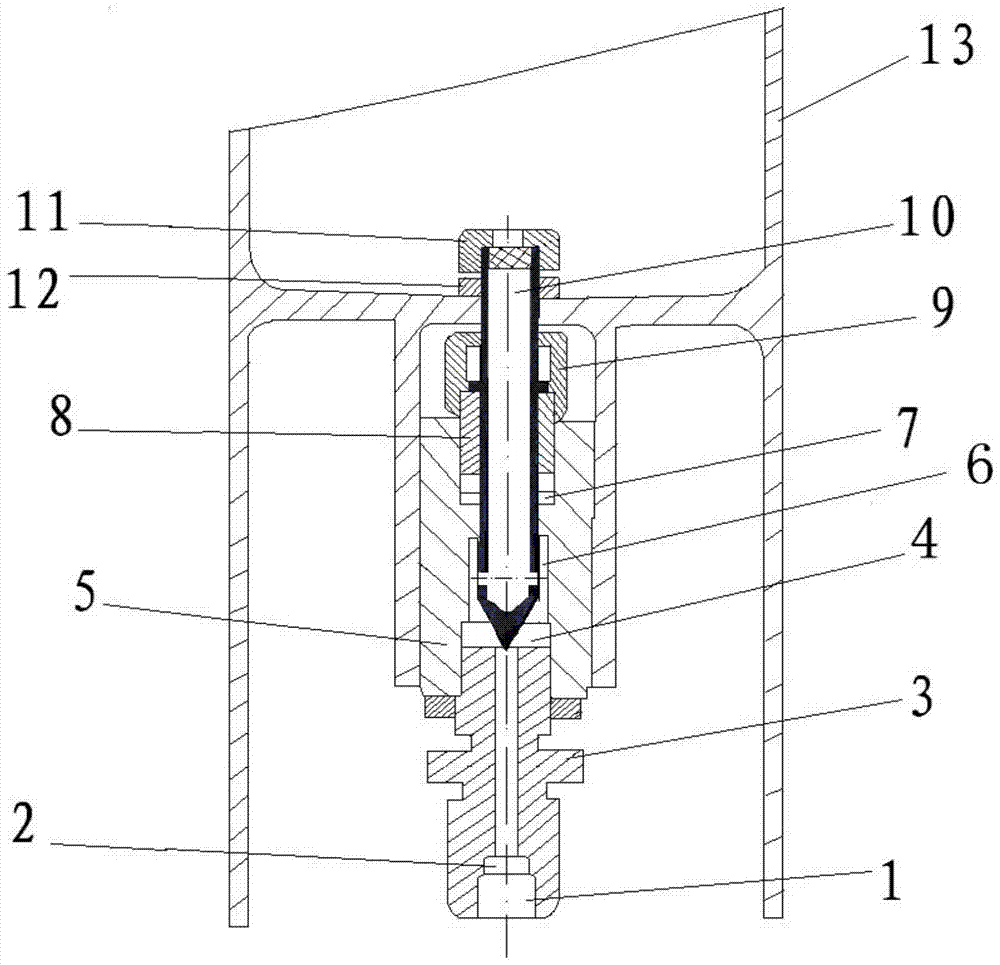

[0014] Such as figure 1 As shown in the embodiment of the present invention, a needle-shaped bottle valve with a tubular valve needle, the valve body 5 is equipped with a joint body 3 and a tubular valve needle 10; A ring groove 6 is formed; the inside of the joint body 3 is processed with an oxygen channel, and a top wire 1 is installed at the lower end of the oxygen channel, and a filter screen 2 is installed on the top of the top wire 1; the valve body 5 includes a tubular valve needle 10 , the upper end of the tubular valve needle 10 is screwed with a holed lock nut 11 and a damping block 12, the guide sleeve 8 is fixed in the middle of the tubular valve needle 10, and the upper part of the guide sleeve 8 is equipped with a compression nut 9, nylon The gasket 7 and the O-shaped sealing ring are set on the lower part of the tubular valve needle 10 , and the valve gasket 4 is installed on the lower end of the tubular valve needle 10 .

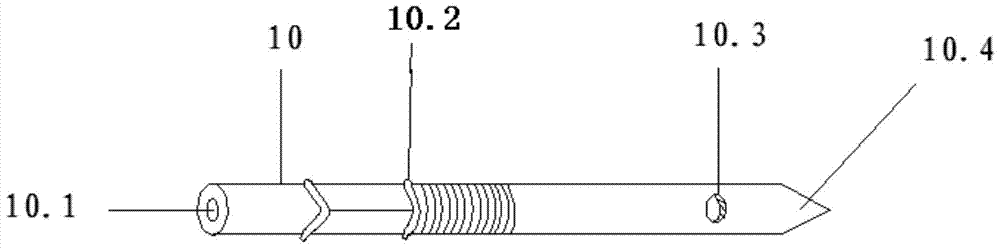

[0015] Such as figure 2 As shown, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com