Magnet powders, bonded magnets, and electric motors

A technology of bonding magnets and motors, applied in the field of magnet powder, to achieve high coercive force and reduce the deterioration of magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

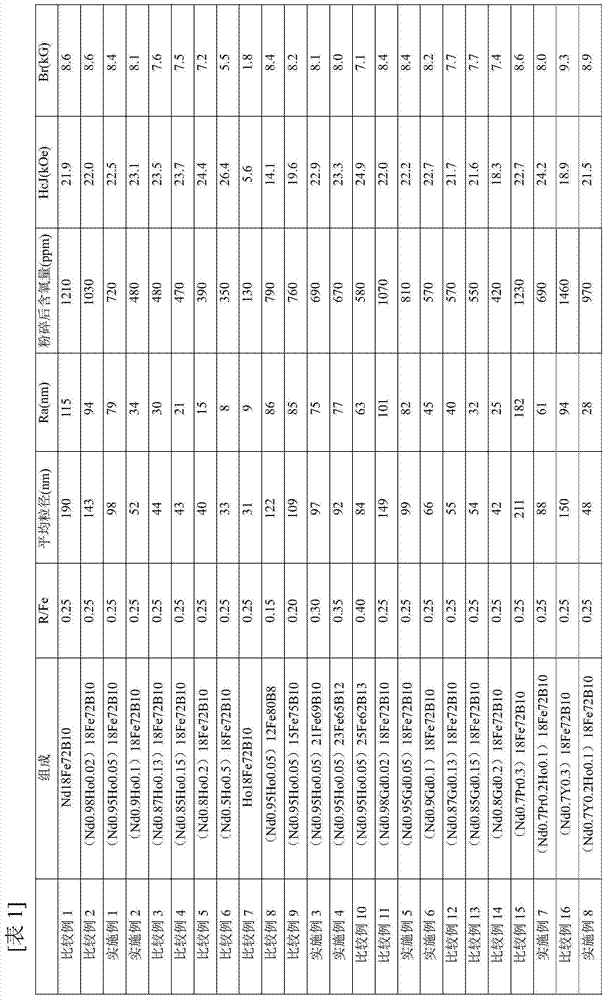

[0044] A quenched ribbon was produced in the same manner as in Comparative Example 1, except that R in the raw material composition was set to R1=Nd and R2=Ho, and R2 / (R1+R2)=0.05 in atomic ratio. Then, the average primary particle diameter and the deviation Ra were obtained from the results of FE-SEM in the same manner as in Comparative Example 1. After pulverizing the quenched ribbon, the oxygen content was measured in the same manner as in Comparative Example 1, and HcJ and Br were obtained from the VSM measurement results. The results are shown in Table 1.

Embodiment 2

[0046] A quenched ribbon was produced in the same manner as in Comparative Example 1, except that R in the raw material composition was set to R1=Nd and R2=Ho, and R2 / (R1+R2)=0.1 in atomic ratio. Then, the average primary particle diameter and the deviation Ra were obtained from the results of FE-SEM in the same manner as in Comparative Example 1. After pulverizing the quenched ribbon, the oxygen content was measured in the same manner as in Comparative Example 1, and HcJ and Br were obtained from the VSM measurement results. The results are shown in Table 1.

Embodiment 3

[0062] A quenched ribbon was produced in the same manner as in Example 1 except that the raw material composition was set to 21at%R-69at%Fe-10at%B. Then, the average primary particle diameter and the deviation Ra were obtained from the results of FE-SEM in the same manner as in Comparative Example 1. After pulverizing the quenched ribbon, the oxygen content was measured in the same manner as in Comparative Example 1, and HcJ and Br were obtained from the VSM measurement results. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen content | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com