Self-cleaning filter and washing machine

A self-cleaning filter and filter technology, which is applied to other washing machines, fixed filter elements, filter separation, etc., can solve the problems of automatic cleaning, filter debris accumulation, filter failure, etc., and is suitable for popularization and use , cheap price, scientific design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

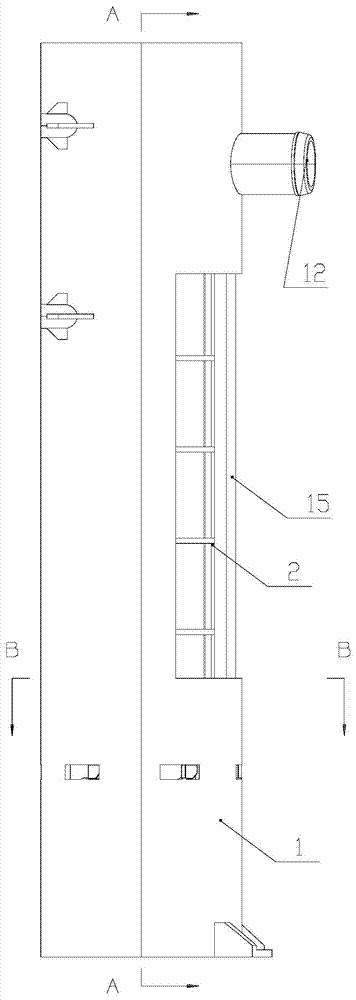

[0038] like Figures 1 to 6 As shown, in this embodiment, the filter is composed of a cylindrical shell 1, and the bottom of the shell 1 is sleeved with a base 5, so that an independent and airtight accommodation space is formed inside the shell 1, which can be opened from the bottom Opens detachably. In this embodiment, the housing 1 can also be a columnar structure with a cross-section of any geometric shape such as square, quadrilateral, ellipse, and combinations thereof.

[0039]The outer periphery of the base 5 is provided with at least one buckle 51 that protrudes outwards and is on the same level, and the housing 1 is provided with a mounting hole that matches the buckle, so that the buckle 51 and the mounting hole form a buckle connection, so that the base 5 and the housing 1 are fixed to each other through the snap connection. At least one sealing ring 52 is provided on the contact surface between the base 5 and the housing 1 to ensure the tightness of the inner spa...

Embodiment 2

[0042] like Figures 1 to 6 As shown, at least one cleaning particle 3 is provided in the first part surrounded by the inner side of the filter screen 4, and the cleaning particle 3 can move in the first part with the water flow flowing into the housing from the water inlet 11 to clean the filter screen. 4. Wash the dirt and impurities attached to the filter to achieve the purpose of self-cleaning of the filter.

[0043] In this embodiment, during the working process of the filter, water flows into the first part of the filter from the water inlet at the lower part of the housing, and the water flows through the filter screen to attach the dirt in the water to the filter screen to achieve the purpose of filtering the water flow; The final water flow enters the second part and flows out of the filter through the water outlet provided on the upper part of the housing; at the same time, the cleaning particles in the first part move with the water flow in the first part. During th...

Embodiment 3

[0046] like Image 6 As shown, the lower part of the base 5 is provided with an "L"-shaped water inlet pipeline 55, one end of which extends horizontally to form the water inlet 11, and the horizontal extension end protrudes from the outer periphery of the base 5 to facilitate the connection between the water inlet and the water inlet. The external connecting pipeline is connected; the other end is vertically extended, and the vertically extended end extends to the top surface of the base 5 to communicate with the first part inside the housing 1; preferably, the "L" shaped The vertical extension end of the water pipeline 55 is arranged along the axis of the housing 1 .

[0047] In this embodiment, the skeleton 2 is composed of an annular tube 21 at the bottom, at least two vertical beams 22 that extend upward from the circular tube 21 and are arranged symmetrically with respect to the axis of the housing, and a bottom-down beam connected to the upper part of each vertical beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com