Preparation method for micro and nano PET fiber with large pore volumes

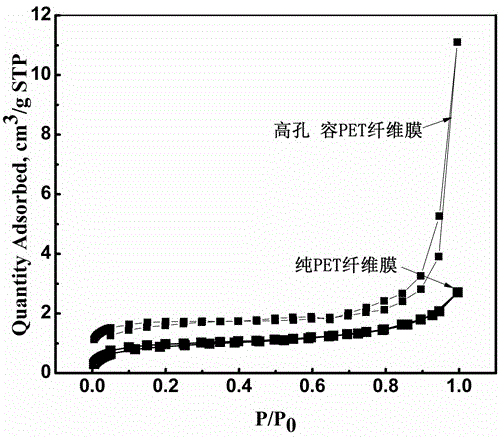

A micro-nano, porous carbon fiber technology, applied in fiber processing, textiles and papermaking, non-woven fabrics, etc., can solve the problems of application limitations, low strength of PET micro-nano fibers, limited porosity and specific surface area, etc. The method is simple and feasible , the effect of improving mechanical properties and spinning stability, and improving specific surface area and pore volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The preparation method of the high pore volume micronano PET fiber of the present embodiment is as follows:

[0017] First dry the PET slices and self-made porous carbon fiber (refer to patent CN104692381A for the method) in a vacuum oven, measure 20 mL of a mixed solvent of trifluoroacetic acid and methylene chloride with a volume ratio of 2:1 in an iodine bottle, and weigh the PET A mixed solution with a solution concentration of 12% was prepared from 3% by mass porous carbon fiber and PET. The composite fibers were prepared by electrostatic spinning on a magnetic stirrer at room temperature for 8 hours. The preparation conditions were as follows: the receiving distance was 16 cm, the spinning voltage was 20-25 kV, and the propulsion speed was 0.001 mm / s. The prepared composite fiber membrane was soaked in 10% NaOH solution for 10 min, rinsed with distilled water several times, and then dried in a vacuum oven at 100 °C for 24 h to obtain micro-nano PET fibers with hig...

Embodiment 2

[0020] The preparation method of the high pore volume micronano PET fiber of the present embodiment is as follows:

[0021] The PET slices and self-made porous carbon fibers were first dried in a vacuum oven. Measure 20 mL of a mixed solvent of trifluoroacetic acid and dichloromethane with a volume ratio of 3:1 in an iodine measuring bottle. Weigh the porous carbon fiber with 2% PET mass and PET to make a mixed solution with a solution concentration of 16%. The composite fibers were prepared by electrostatic spinning on a magnetic stirrer at room temperature for 8 hours. The preparation conditions were as follows: the receiving distance was 16 cm, the spinning voltage was 20-25 kV, and the propulsion speed was 0.001 mm / s. The prepared composite fiber membrane was soaked in a 5% NaOH solution for 15 min, rinsed with distilled water several times, and then dried in a vacuum oven at 100 °C for 24 h to obtain micro-nano PET fibers with high pore volume.

Embodiment 3

[0023] The preparation method of the high pore volume micronano PET fiber of the present embodiment is as follows:

[0024] The PET slices and self-made porous carbon fibers were first dried in a vacuum oven. Measure 20 mL of a mixed solvent of trifluoroacetic acid and dichloromethane with a volume ratio of 1:1 in an iodine measuring bottle. Weigh 1% of the PET mass of porous carbon fiber and PET to prepare a mixed solution with a solution concentration of 16%. The composite fibers were prepared by electrostatic spinning on a magnetic stirrer at room temperature for 8 hours. The preparation conditions were as follows: the receiving distance was 16 cm, the spinning voltage was 20-25 kV, and the propulsion speed was 0.001 mm / s. The prepared composite fiber membrane was soaked in 8% NaOH solution for 15 min, washed several times with distilled water, and then dried in a vacuum oven at 100 °C for 24 h to obtain micro-nano PET fibers with high pore volume.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com