A method for manufacturing a large-scale heat-treated aluminum alloy flat ingot

A manufacturing method and aluminum alloy technology, which is applied in the field of manufacturing aluminum alloy flat ingots, can solve the problems of inability to roll out wide and thick plates with excellent performance, and low casting yield, so as to reduce casting stress, improve welding performance, and refine grain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

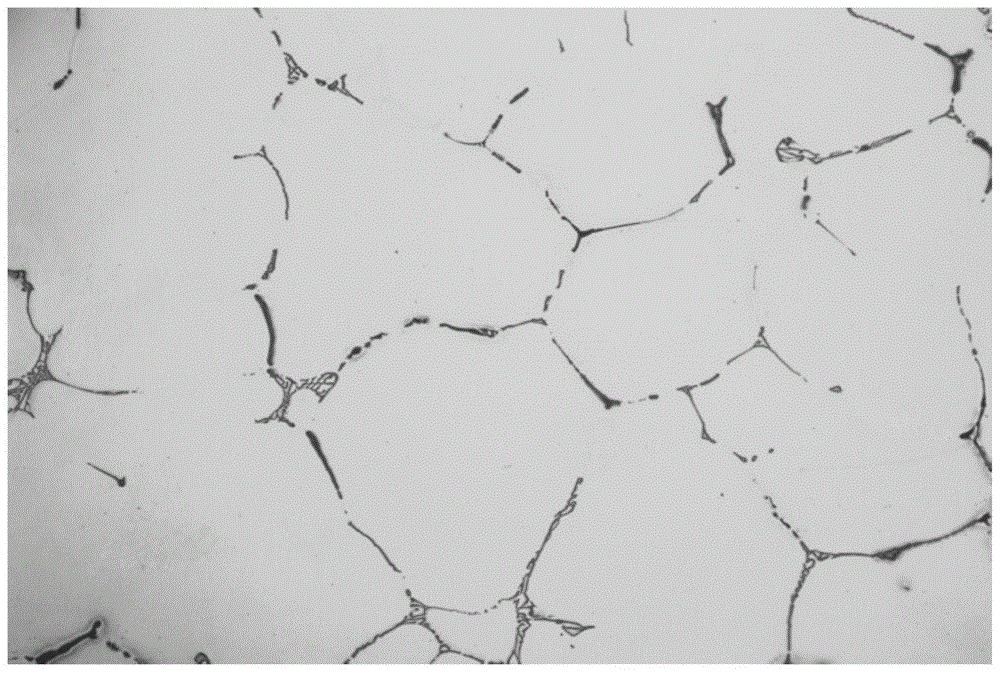

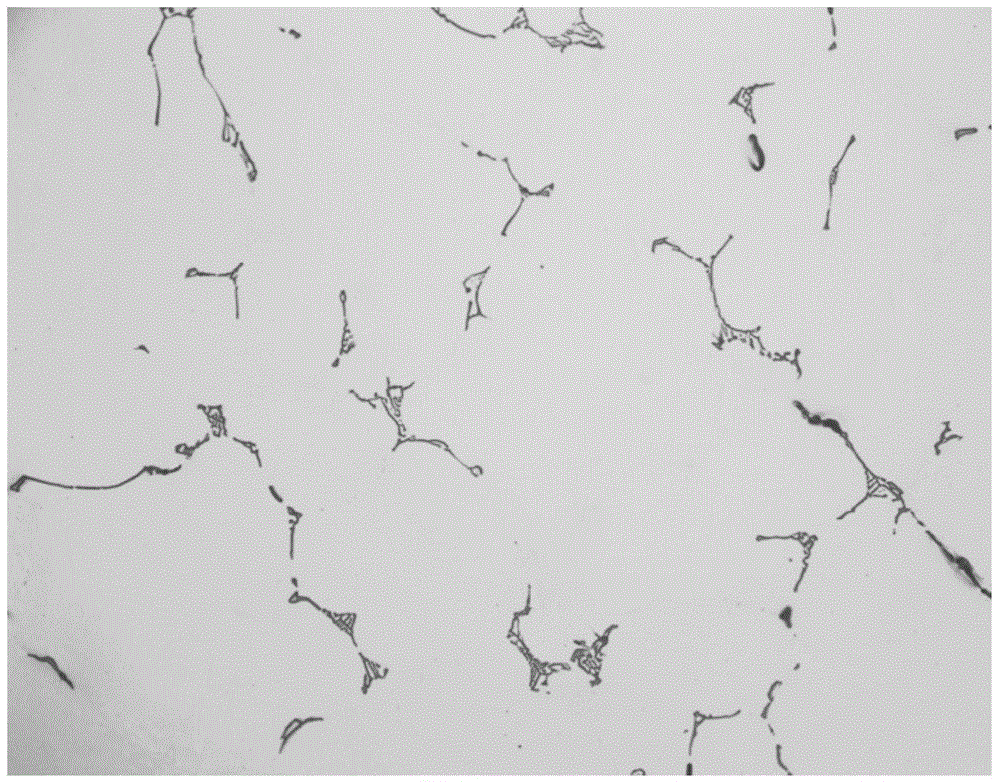

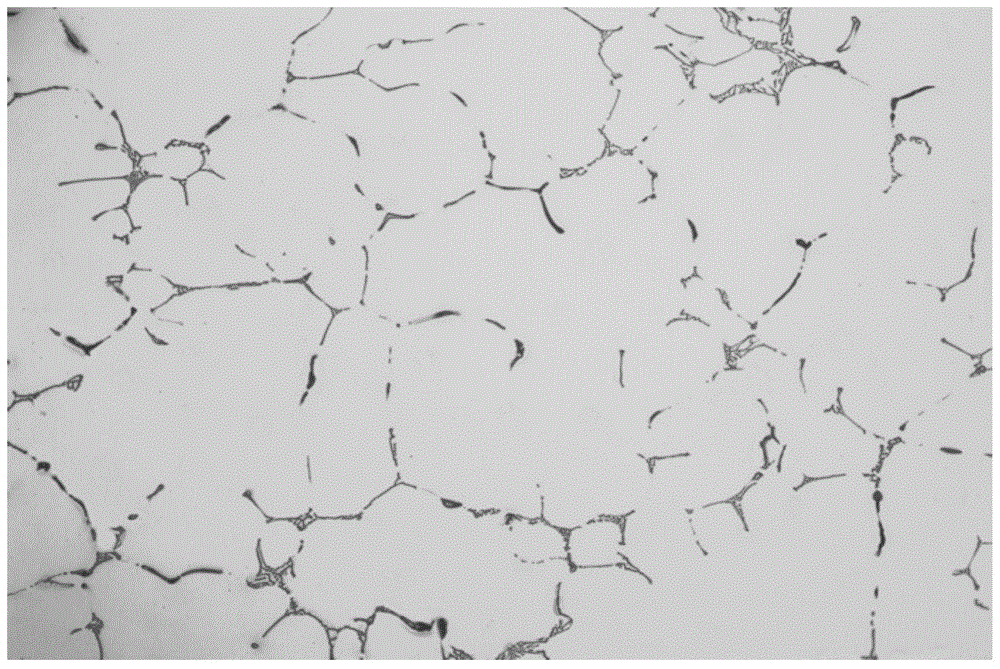

Image

Examples

specific Embodiment approach 1

[0024] Specific implementation mode 1: This implementation mode is a method for manufacturing a large-scale heat-treated aluminum alloy slab that can be strengthened, which is completed according to the following steps:

[0025] 1. Weighing materials: Si: 0.5%~0.7%, Cu: 0.15%~0.25%, Mg: 0.9%~1.1%, Cr: 0.1%~0.25%, and the balance Al according to the mass percentage of each element, weighed respectively Pure aluminum ingots, Al-Si master alloys, Al-Cu master alloys, Cr additives and pure Mg ingots;

[0026] 2. Smelting: Add the pure aluminum ingot, Al-Si master alloy, Al-Cu master alloy, Cr additive and pure Mg ingot weighed in step 1 into the natural gas furnace in sequence, and then heat the furnace at a temperature of 720°C to 760°C Melting until the pure aluminum ingot, Al-Si master alloy, Al-Cu master alloy, Cr additive and pure Mg ingot are all melted, and then under the conditions of temperature 720℃~760℃ and stirring speed 1m / s~1.5m / s Stir and smelt for 5 minutes to 10 ...

specific Embodiment approach 2

[0041]Embodiment 2: The difference between this embodiment and Embodiment 1 is that the mass fraction of Al in the pure aluminum ingot described in step 1 is greater than 99.98%. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0042] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the mass fraction of Al in the Al-Si master alloy described in step 1 is 80%, and the mass fraction of Si is 20%. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com