A kind of reversible thermosensitive color-changing dye, preparation method and application thereof

A technology of temperature-sensitive discoloration and dyes, applied in applications, organic dyes, household appliances, etc., can solve the problems of high toxicity, low stability, and reduced toxicity of dyes, and achieve reduced toxicity, reduced biocompatibility, structural adjustment and The effect of enhanced design capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

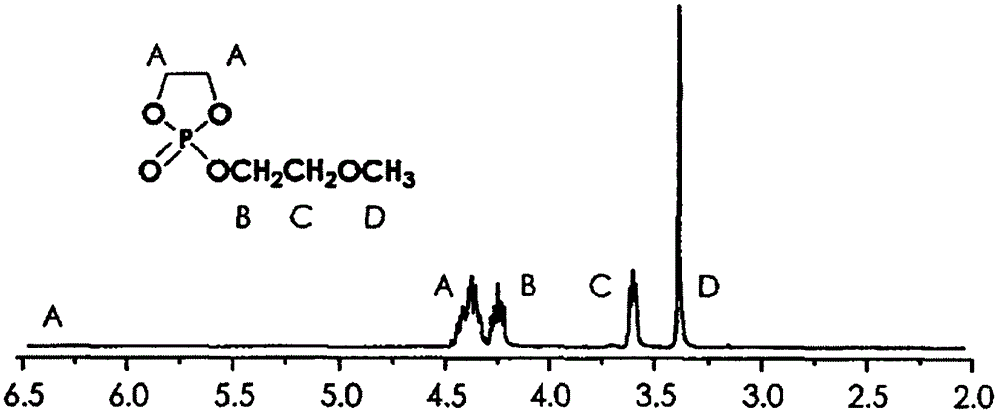

[0032] 1. Dissolve 2-methoxyethanol (7.67g, 100.8mmol) and equimolar amount of triethylamine (10.20g, 100.8mmol) in 100mL tetrahydrofuran, and cool to -5°C. Under stirring condition, 100 mL of 2-chloro-2-oxo-1,3,2-dioxaphospholane (14.36 g, 100.8 mmol) in tetrahydrofuran was slowly added dropwise thereto. After the dropwise addition, continue to react at -5°C for 12 hours, under N 2 Under the protection of the atmosphere, filter and remove the precipitate. The filtrate was concentrated and distilled under reduced pressure twice to give the product 2-methoxyethyl-2-oxo-1,3,2-dioxaphospholane as a colorless liquid.

[0033] See attached figure 1 , which is the NMR spectrum of the product 2-methoxyethyl-2-oxo-1,3,2-dioxaphospholane in this example, the chemical shift in the spectrum is consistent with the expected structure, confirming that The compound was successfully prepared.

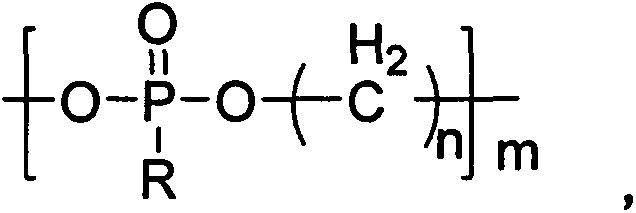

[0034] 2. Aluminum triisopropoxide (155mmol) was dissolved in 92mL of tetrahydrofuran, and the ...

Embodiment 2

[0037] 1. Dissolve 2-ethoxyethanol (9.07g, 100.8mmol) and equimolar amount of triethylamine (10.20g, 100.8mmol) in 100mL tetrahydrofuran, and cool to -5°C. Under stirring condition, 100 mL of 2-chloro-2-oxo-1,3,2-dioxaphospholane (14.36 g, 100.8 mmol) in tetrahydrofuran was slowly added dropwise thereto. After the dropwise addition, continue to react at -5°C for 12 hours, under N 2Under the protection of the atmosphere, filter and remove the precipitate. The filtrate was concentrated and distilled under reduced pressure twice to give the product 2-ethoxyethyl-2-oxo-1,3,2-dioxaphospholane as a colorless liquid.

[0038] 2. Aluminum triisopropoxide (155mmol) was dissolved in 92mL of tetrahydrofuran, and the 2-ethoxyethyl-2-oxo-1,3,2-dioxaphospholane (2.99 g, 13.1 mmol) was dissolved in tetrahydrofuran (22.51 g) solution, mixed, and reacted at 20°C. After 4 h of reaction, excess acetic acid was added to the solution to terminate the reaction. The reaction solution was concent...

Embodiment 3

[0041] 1. Dissolve 2-butoxyethanol (13.07g, 100.8mmol) and equimolar amount of triethylamine (10.20g, 100.8mmol) in 100mL tetrahydrofuran, and cool to -5°C. Under stirring conditions, 100 mL of 2-chloro-2-oxo-1,3,2-dioxaphospholane (14.36 g, 100.8 mmol) in tetrahydrofuran was slowly added dropwise thereto. After the dropwise addition, continue to react at -5°C for 12 hours, under N 2 Under the protection of the atmosphere, filter and remove the precipitate. The filtrate was concentrated and distilled under reduced pressure twice to give the product 2-butoxyethyl-2-oxo-1,3,2-dioxaphospholane as a colorless liquid.

[0042] 2. Dissolving aluminum triisopropoxide (155mmol) in 92mL tetrahydrofuran, the 2-butoxyethyl-2-oxo-1,3,2-dioxaphospholane (3.49 g, 13.1 mmol) was dissolved in tetrahydrofuran (22.51 g) solution, mixed, and reacted at 20°C. After 4 h of reaction, excess acetic acid was added to the solution to terminate the reaction. The reaction solution was concentrated, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com