Preparation method of 1-isopropyl-3-tert-butylthiourea

A technology of tert-butyl thiourea and isopropyl, applied in the field of preparation of pesticide intermediates, can solve the problems of affecting the reaction yield and efficiency, difficulty in three-waste treatment, easy generation of waste residues, etc., and achieves low cost, reduced risk, Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

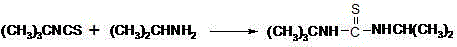

Image

Examples

Embodiment 1

[0018] Add 900kg of ammonium thiocyanate and 1000kg of water to the replacement kettle, stir to dissolve the ammonium thiocyanate; then add 1000kg of 85% tert-butanol, and stir for 20 minutes; slowly raise the temperature to 75°C, and then add 1443.4 industrial hydrochloric acid dropwise under reflux kg (mass concentration 29%), the dropping time is 2 hours, and after the dropping is completed, it is kept under reflux for 4 hours; then the temperature is lowered to 90°C, and it is left to stand for 30 minutes. The principle of different degrees of reduction is used to remove the water in layers, and the acidic waste water is sent to the waste water treatment tank. After washing again at 90°C, a light yellow transparent liquid is obtained; add 20kg of concentrated sulfuric acid to the light yellow transparent liquid, raise the temperature to 55°C, and keep it warm for 4 hours. , The insolubles were filtered off to obtain 1232.2 kg of 98.2% tert-butyl isothiocyanate, with a yield...

Embodiment 2

[0021] Add 900kg of ammonium thiocyanate and 450kg of water to the replacement kettle, stir to dissolve the ammonium thiocyanate; then add 1225kg of 85% tert-butanol and stir for 20 minutes; slowly raise the temperature to 75°C, and then add 1424kg of industrial hydrochloric acid dropwise under reflux (mass concentration 30%), the dropping time is 1 hour, and after the dropping is completed, it is kept under reflux for 2 hours; then the temperature is lowered to 90°C, and it is left to stand for 30 minutes. The specific gravity of various substances varies with the increase of temperature. The principle of level reduction is used to remove water in layers, and the acidic waste water is sent to the waste water treatment tank. After washing again at 90°C, a light yellow transparent liquid is obtained; add 6.1kg of concentrated sulfuric acid to the light yellow transparent liquid, heat up to 60°C, and keep warm for 6 hours. , The insolubles were filtered off to obtain 1238.4 kg of...

Embodiment 3

[0024] Add 900kg of ammonium thiocyanate and 1800kg of water to the replacement kettle, stir to dissolve the ammonium thiocyanate; then add 918.6kg of 85% tert-butanol, and stir for 20 minutes; slowly raise the temperature to 70°C, and then add industrial hydrochloric acid dropwise under reflux 2563kg (mass concentration 30%), the time of dropping is 3 hours, and after the dropping is completed, it is kept at reflux for 4 hours; then the temperature is lowered to 70°C, and it is left to stand for 30 minutes. The specific gravity of various substances increases with the temperature. The principle of different degrees of reduction is used to remove water in layers, and the acidic waste water is sent to the waste water treatment tank. After washing again at 90°C, a light yellow transparent liquid is obtained; add 6.1kg of concentrated sulfuric acid to the light yellow transparent liquid, heat up to 70°C, and keep warm for 3 After hours, the insoluble matter was filtered off to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com