Method and device for recycling industrial waste containing nylon 66 triethylene glycol

A technology of industrial waste and triethylene glycol, applied in ether separation/purification, ether preparation, etc., can solve the problems of unreasonable and effective recycling of triethylene glycol industrial waste, environmental pollution, etc., and achieve simple structure, precise parameter control, and reasonable connection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

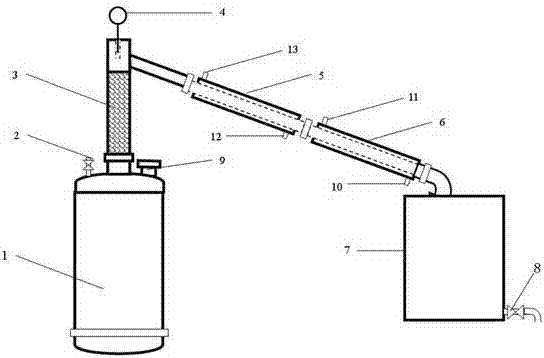

[0020] Embodiment 1: A kind of device that is used to reclaim industrial waste containing nylon 66 triethylene glycol, see figure 1 , the device comprises a still 1, a safety valve 2 is installed on one side of the top of the still 1, and a feed inlet 9 is arranged on the other side, the top of the still 1 is a fractionating column 3, and an air outlet is arranged on the side of the upper part of the fractionating column 3, A thermometer 4 is inserted at the gas outlet, and the still temperature is detected in time by the thermometer. Connect the first cooler 5 and the second cooler 6 successively through the gas pipeline at the gas outlet, the angle between the first cooler 5 and the second cooler 6 and the fractionation column is 75°, the inner pipe of the first cooler 5 and the The inner pipes of the second cooler 6 are connected with flanges. The water outlet pipe on the upper part of the second cooler 6 is connected with the water inlet pipe on the lower part of the firs...

Embodiment 2

[0025] Embodiment 2: a kind of recycling method that contains nylon 66 triethylene glycol industrial waste, this method is implemented with the device described in embodiment 1, is specifically: at first, waste pretreatment: use electricity to contain 20%~30% of the triethylene glycol industrial waste swollen into a paste of nylon 66 is heated to 70°C, heat-preserved and settled for 2 hours, and heavy impurities such as sand are removed. Waste plastic bags, sawdust and other light impurities, the waste after precipitation and filtration, all impurities in the waste except water and swollen nylon 66 have been removed;

[0026] Then evaporate the water: Put the pretreated waste into an atmospheric distillation kettle to heat and evaporate, the evaporation temperature is 100°C, and the water will be discharged from the outlet of the second cooler in a vapor state. Castor oil can be added to the proportion of castor oil, which can reduce the viscosity of the waste, reduce the surf...

Embodiment 3

[0029]Embodiment 3: a kind of recycling method that contains nylon 66 triethylene glycol industrial waste, this method is implemented with the device described in embodiment 1, is specifically: at first, waste pretreatment: use electricity to contain 20%~30% of the triethylene glycol industrial waste swollen into a paste of nylon 66 is heated to 60°C, heat-preserved and settled for 1.8 hours, and heavy impurities such as sand are removed. Waste plastic bags, sawdust and other light impurities, the waste after precipitation and filtration, all impurities in the waste except water and swollen nylon 66 have been removed;

[0030] Then evaporate the water: put the pretreated waste into an atmospheric still to heat and evaporate, the evaporation temperature is 100°C, and the water will be discharged from the outlet of the second cooler in a vapor state. After evaporation, add 0.4% to the waste The ratio of adding kale seed oil.

[0031] Then start the cooling device: continue heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com