Designing and manufacturing method of powder injection molding piston ring

A technology of powder injection molding and manufacturing methods, which is applied in the fields of turbochargers, reciprocating machinery and general mechanical seals, and internal combustion engines. The effect of high selectivity and design freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in combination with specific implementations according to the accompanying drawings.

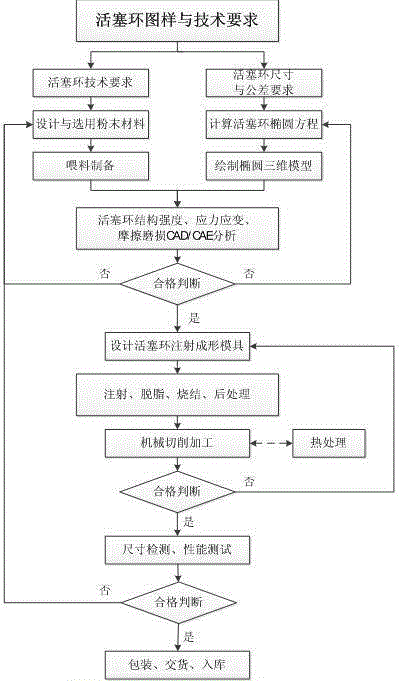

[0031] A method for designing and manufacturing an oval piston ring by powder injection molding, which comprises the following steps:

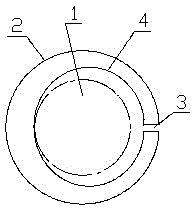

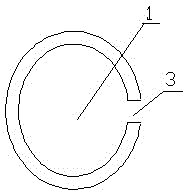

[0032] (1) Product design: According to the performance requirements of the three-dimensional oval piston ring product, design the three-dimensional ellipse equation, design the free opening gap size of the three-dimensional oval piston ring (such as 3, 3.5, 4, 4.5, 5mm), and design the injection molding mold;

[0033] (2) Computer-aided engineering analysis: conduct engineering analysis on structural strength, stress-strain, friction and wear of the designed three-dimensional elliptical piston ring product;

[0034] (3) Select or design materials: According to engineering anal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com