Single nanometer pile face preparation method of crystalline silicon solar cell

A nano-suede and solar cell technology, which is applied in the field of solar cells, can solve the problems such as the uselessness of nano-suede, and achieve the effects of simple and easy preparation method, reduction of catalytic metal consumption, and improvement of production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

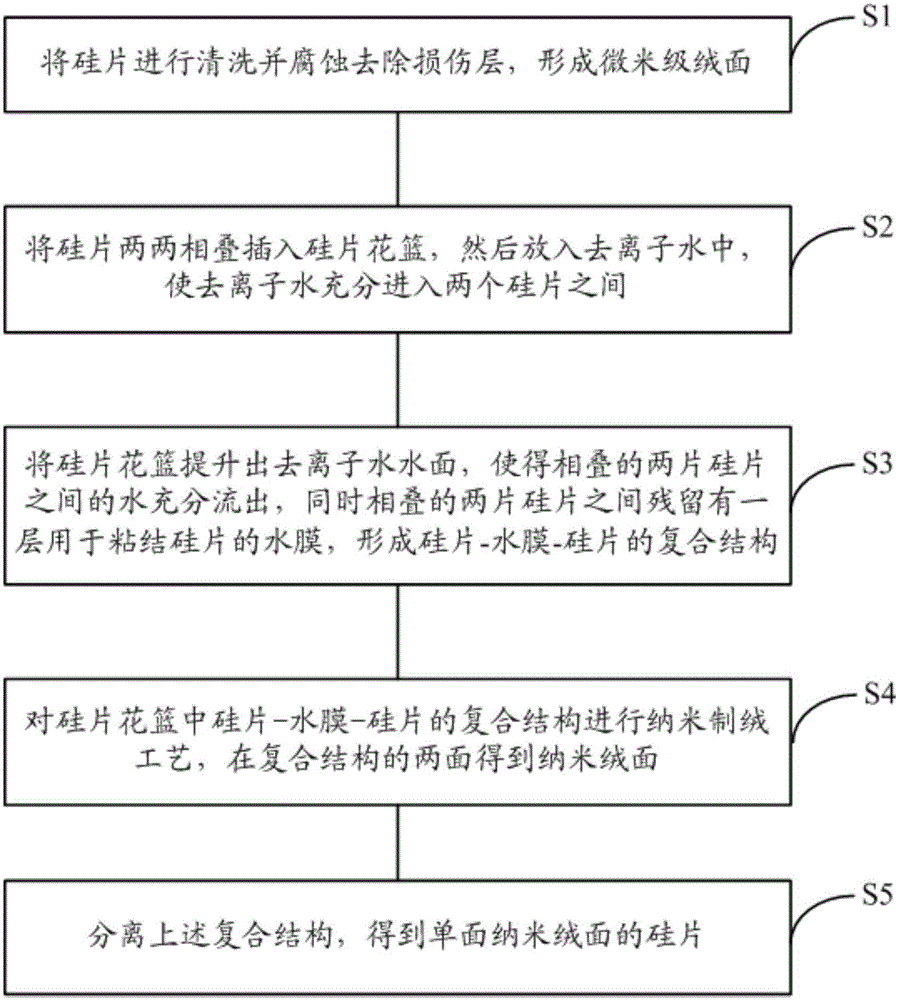

[0058] ginseng figure 1 As shown, the invention discloses a method for preparing a single-sided nano-velvet surface of a crystalline silicon solar cell, comprising the following steps:

[0059] S1. The silicon wafer is cleaned and etched to remove the damaged layer to form a micron-sized suede. The silicon chip in the present invention is a monocrystalline silicon silicon chip or a polycrystalline silicon silicon chip;

[0060] S2. Insert the silicon wafers into the wafer flower basket in two stacks, then put them into the deionized water, and move the silicon wafer flower basket up and down in the deionized water for 1 to 2 minutes, so that the deionized water can fully enter between the two silicon wafers;

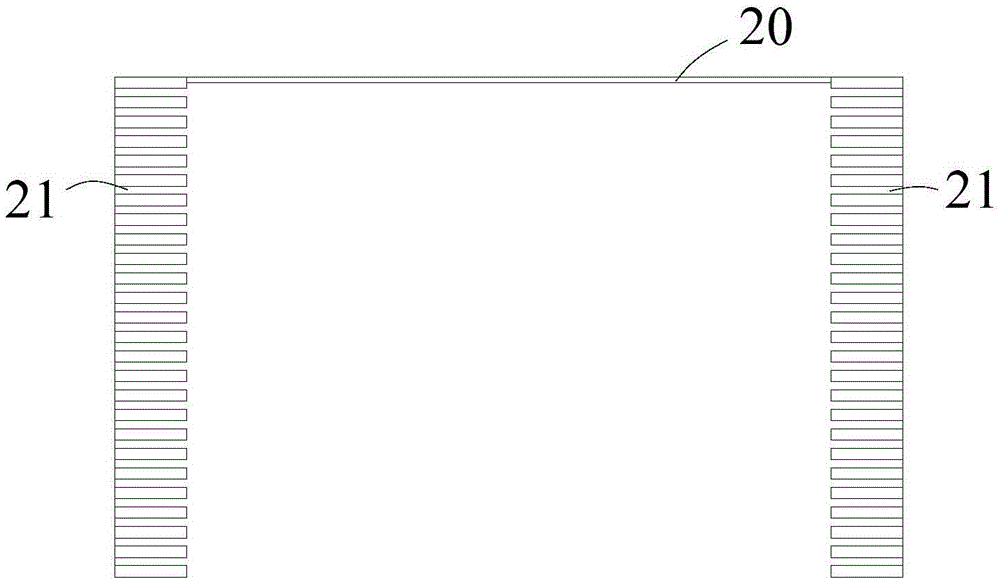

[0061] Schematic diagram of the structure of the silicon wafer flower basket 20 figure 2 As shown, it is exactly the same as the existing silicon flower basket, and the two side walls of the silicon flower basket are correspondingly provided with several slots 21. Pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com