Mistake proofing crimping production method of display panel, structure of display panel, and display panel

A technology of a display panel and a production method, applied in static indicators, nonlinear optics, instruments, etc., can solve problems such as single overlapping alignment, FPC scrap, eye fatigue, etc., and achieve process improvement with low input cost, simple method, The effect of saving judgment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0024] The present invention is achieved in this way, a production method for error-proof crimping of a display panel, the method comprising the following steps:

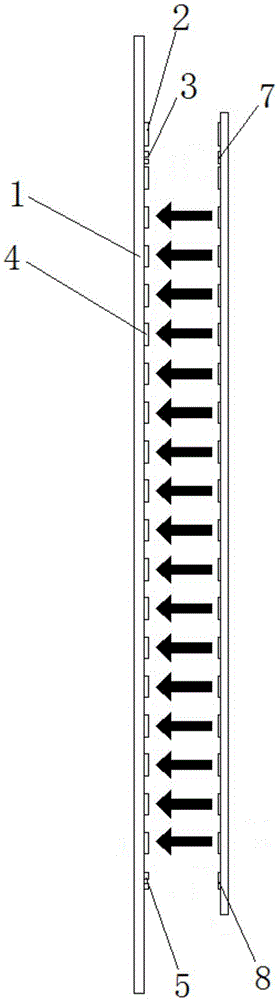

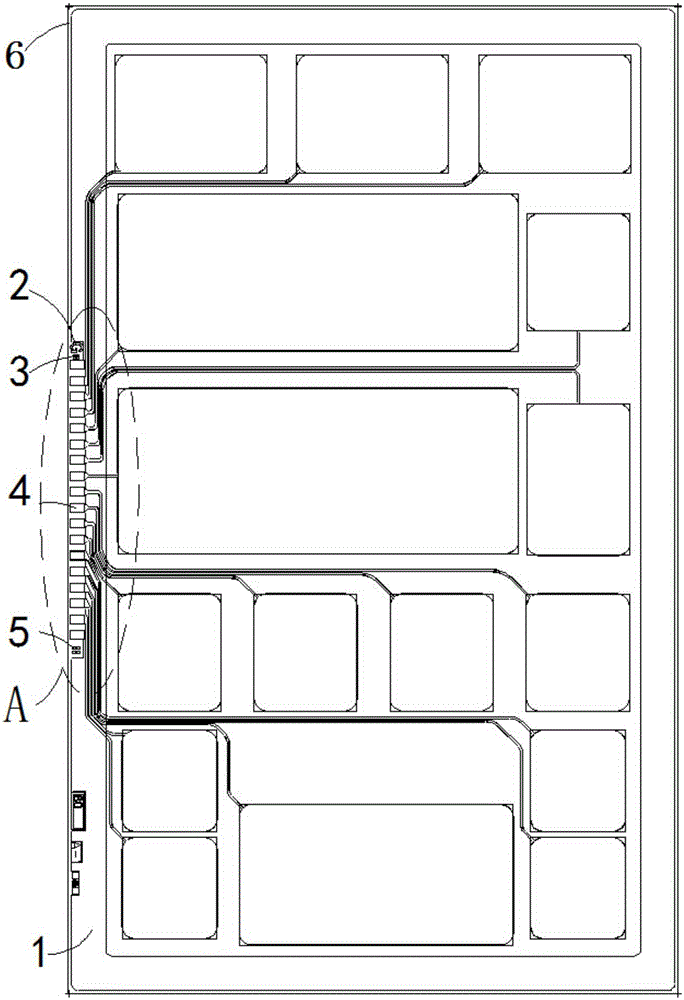

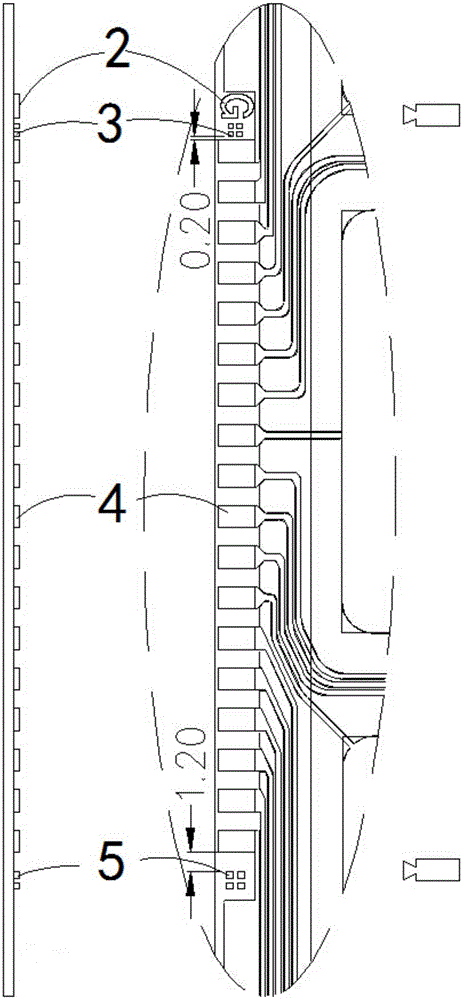

[0025] (1) Set the ITO glass anti-error mark: set the first alignment anti-error mark and the second alignment anti-error mark on the surface of the ITO glass with the PIN bit, the first alignment anti-error mark and the second alignment anti-error mark The error marks are respectively located on both sides of the PIN bit, and are arranged asymmetrically with respect to the PIN bit; the asymmetric arrangement means that the size, position and spacing of the first pair of error prevention marks and the second pair of error prevention marks are different, Instead of the original overlapping alignment, it is easier to judge; this makes the alignment crimping position unique, and also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com