Flexible capsule wave energy power generation device

A power generation device and capsule technology, applied in wind power generation, ocean power generation, engines, etc., can solve the problems of low efficiency of energy absorption, few stages of capacity conversion, low water level amplitude, etc., and achieve strong structural stability and long-term operation Reliable, absorption-boosting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, and the described specific embodiments are only for explaining the present invention, and are not intended to limit the present invention.

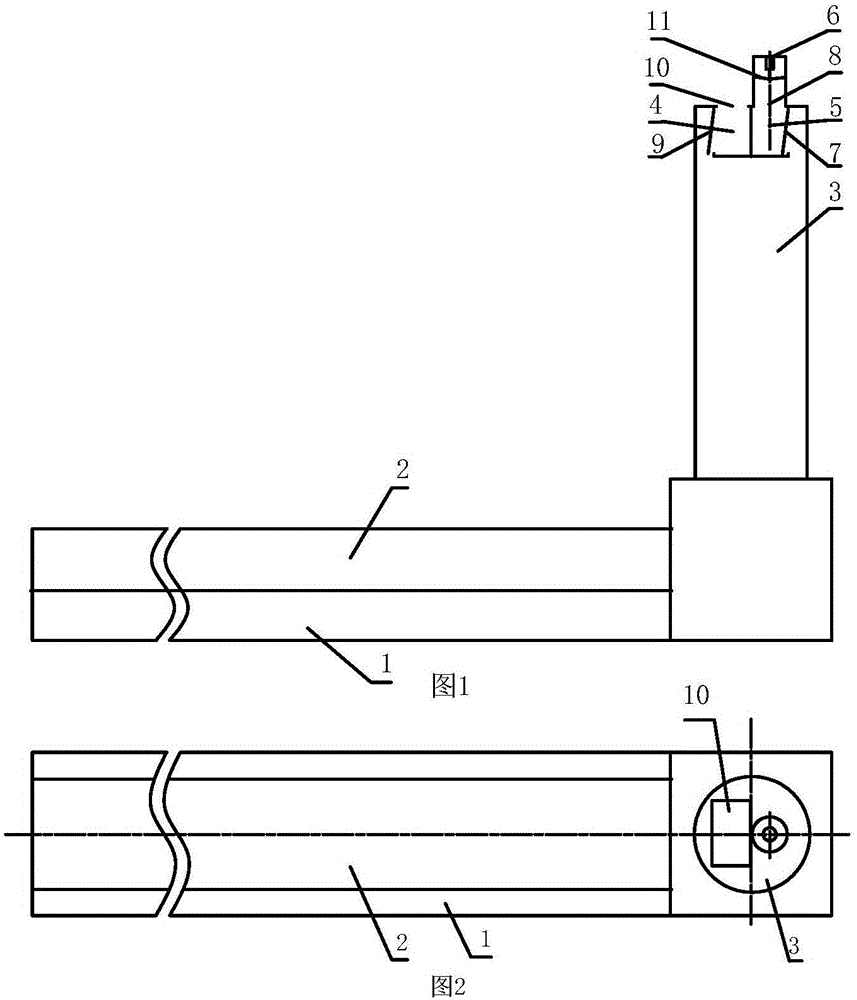

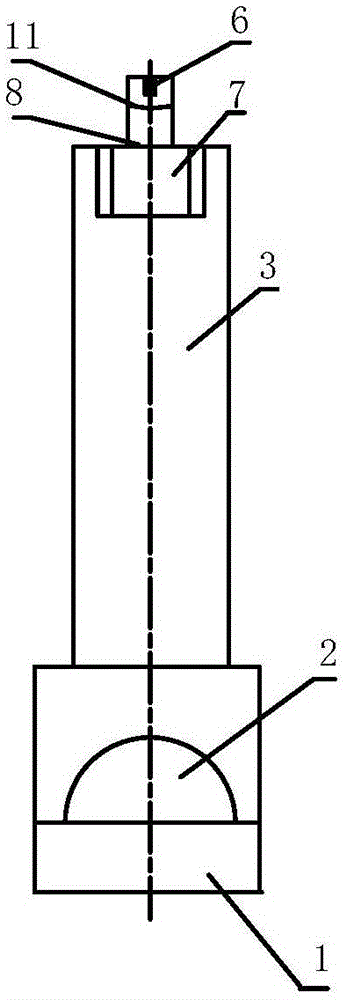

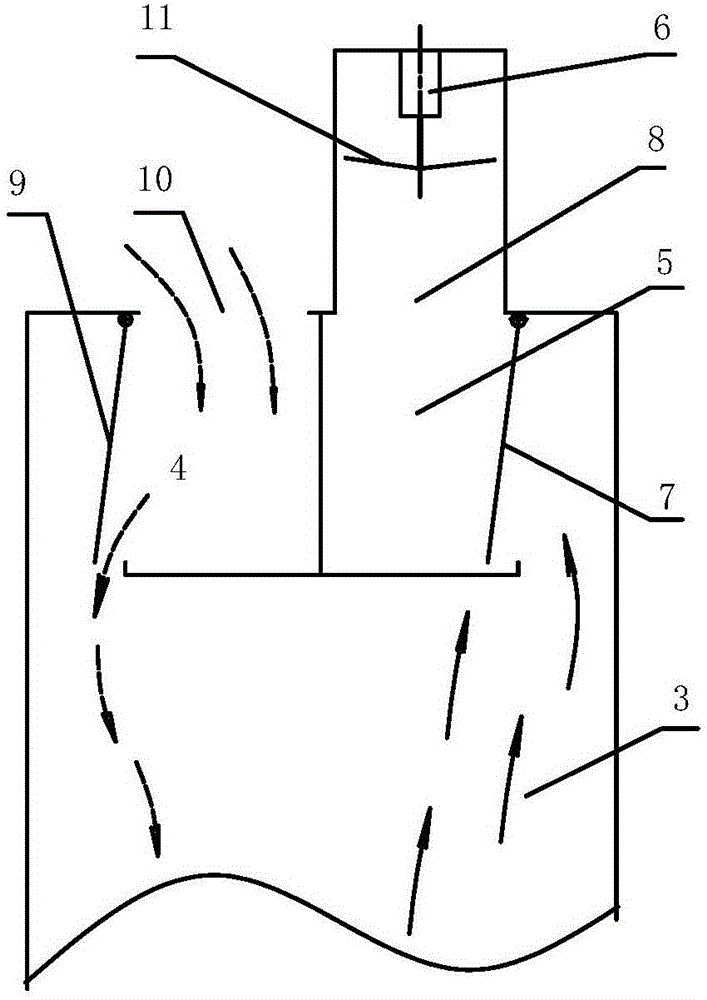

[0026] Such as figure 1 , figure 2 As shown in the figure above, a flexible capsule wave energy power generation device of the present invention includes a base bed 1 fixed on the water bottom, and is characterized in that a silicone tube 2 with a flexible structure is fixed on the base bed 1, and the silicone tube 2 One end is sealed, the other end of the silicone tube 2 is connected with a vertical pipe 3 for transferring water, the top of the vertical pipe 3 is provided with an air intake chamber 4 and an exhaust chamber 5; the air intake chamber 4 is provided with an air intake chamber port 10, an air intake valve 9 is provided between the air intake chamber 4 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com