Internal electricity generation system for gas pipeline and automatic control method

A technology for power generation systems and gas pipelines, applied in pipeline systems, collectors, electric vehicles, etc., can solve problems such as reducing the service life of pipelines, inability to install and use monitoring systems, and complicated installations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

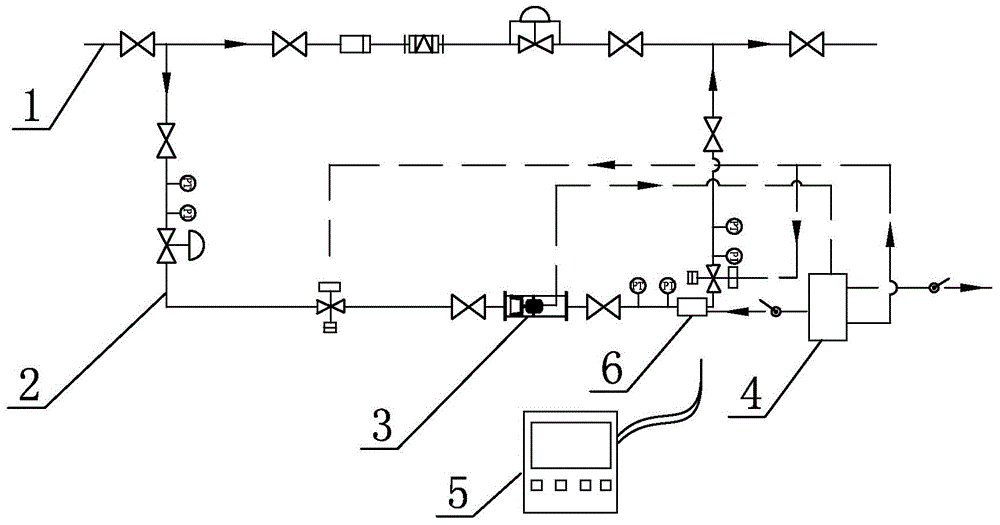

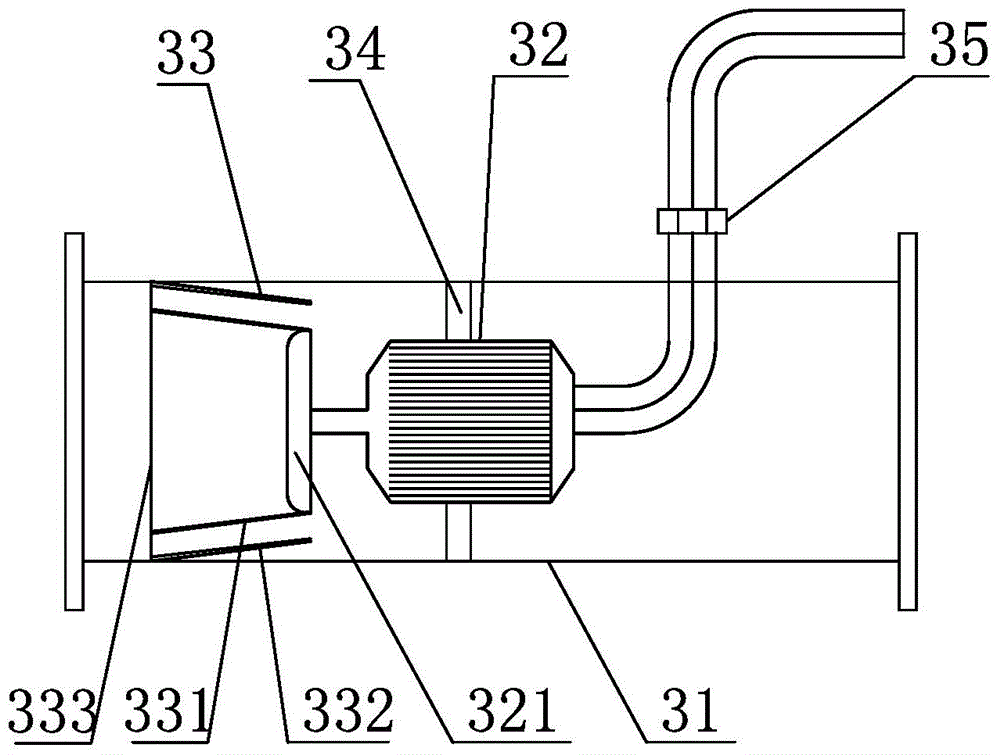

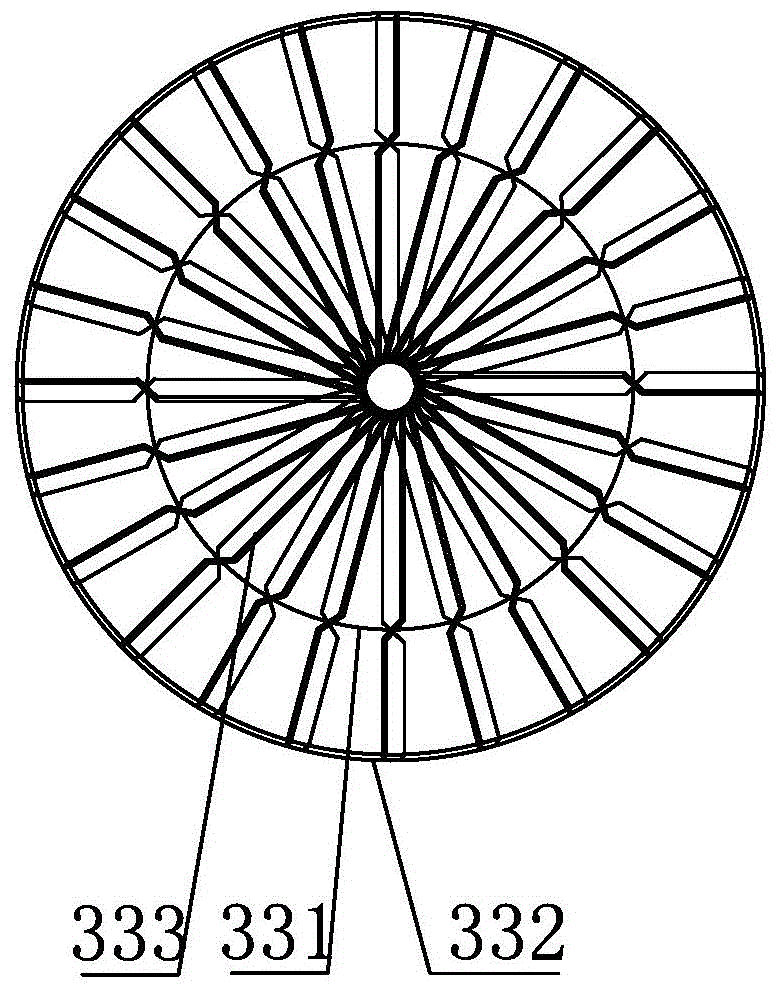

[0023] Such as Figure 1-2 As shown, the gas pipeline built-in power generation system in this embodiment uses the kinetic energy and pressure energy of the natural gas flowing in the main gas pipeline 1 to generate electricity, and provides electric energy to valves, instruments, monitoring, technical defense, etc. in remote areas or areas without power grids. The facility is used, specifically, the power generation system is located on the branch pipeline 2, the branch pipeline 2 is connected in parallel with the main gas pipeline 1, and the power generation device 3 is detachably installed on the branch pipeline 2, and the power generation device 3 includes a tubular casing 31 1. The generator 32 fixed in the casing 31 and the shroud 33 positioned at the power input end of the generator 32, the two ends of the section tubular casing 31 have connecting flanges, and the section tubular casing 31 is detachably installed on the On the branch pipeline 2, the generator 32 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com