Black surface treatment method for electrolytic copper foil

An electrolytic copper foil and surface treatment technology, which is applied in metal material coating process, superimposed layer plating, coating and other directions, can solve the problem that the peel strength, heat resistance and oxidation resistance of electrolytic copper foil products cannot fully meet the actual requirements. Production needs and other issues, to achieve good prospects and application value, good environmental protection characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

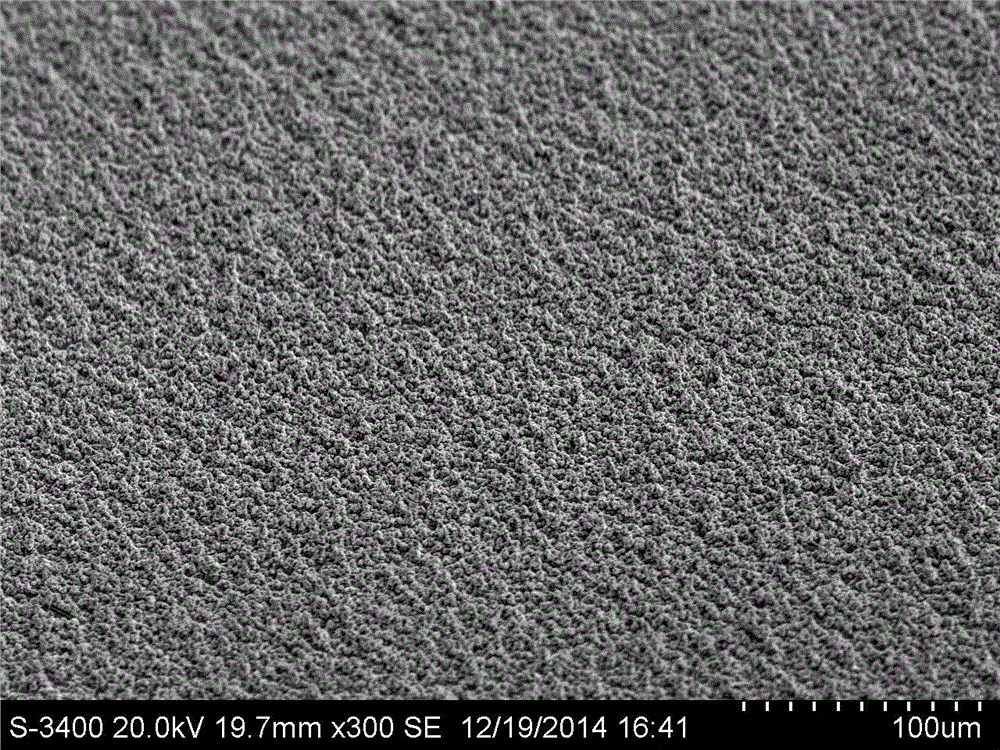

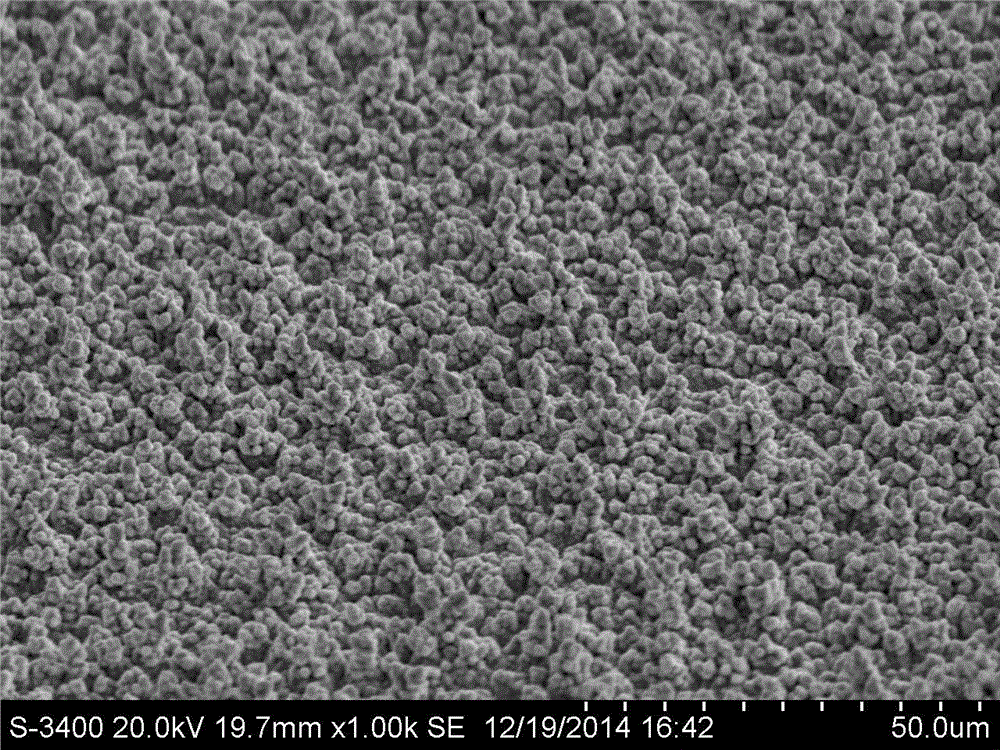

Image

Examples

Embodiment 1

[0030] The method for treating the black surface of the electrolytic copper foil used in this embodiment includes the following steps.

[0031] (1) Raw material treatment, the electrolytic copper foil with a thickness of 12 microns produced by Lingbao Huaxin Copper Foil Co., Ltd. after two roughening and curing treatments was used in this example;

[0032] Specifically, the process conditions of the first roughening and the second roughening are: Cu 2+ Concentration 25g / L, H 2 SO 4 Concentration 43g / L, temperature 25℃, current density 1400A / m 2 ;

[0033] The process conditions of the first curing and the second curing are: Cu 2+ Concentration 37gL, H 2 SO 4 Concentration 45g / L, temperature 30°C, current density 1700A / m 2 .

[0034] (2) Electrodeposition of Ni-Zn binary alloy,

[0035] Preparation of electroplating Ni—Zn binary alloy solution: Potassium pyrophosphate (K 4 P 2 o 7 ), nickel sulfate, zinc sulfate, additive A, additive B, and complexing agent are diss...

Embodiment 2

[0049] The method for treating the black surface of the electrolytic copper foil used in this embodiment includes the following steps.

[0050] (1) Raw material treatment, the raw materials are the same as in Example 1, all of which are electrolytic copper foils with a thickness of 12 microns produced by Lingbao Huaxin Copper Foil Co., Ltd. after two roughening and curing treatments;

[0051] (2) Preparation of electroplating Ni—Zn binary alloy solution, potassium pyrophosphate (K 4 P 2 o 7 ), nickel sulfate, zinc sulfate, additive A, additive B, complexing agent and other substances are dissolved separately and mixed evenly;

[0052] Described additive A is the ammonium chloride that can release ammonium root after dissolving;

[0053] Described additive B adopts Zn, Ag, and its mass ratio is 2:7;

[0054] The complexing agent adopts complexing agent R;

[0055] The concentration levels of each material are as follows:

[0056] K 4 P 2 o 7 , 180g / L; Ni 2+ , 10g / L; Z...

Embodiment 3

[0064] The method for treating the black surface of the electrolytic copper foil used in this embodiment includes the following steps.

[0065] (1) Raw material treatment, the raw materials are the same as in Example 1, which are electrolytic copper foils with a thickness of 12 microns produced by Lingbao Huaxin Copper Foil Co., Ltd. after twice roughening and curing.

[0066] (2) Electrodeposition of Ni-Zn binary alloy,

[0067] Electroplating Ni—Zn binary alloy solution: Potassium pyrophosphate (K 4 P 2 o 7 ), nickel sulfate, zinc sulfate, additive A, additive B, complexing agent and other substances are dissolved separately and mixed evenly;

[0068] The additive A is a mixture of sodium sulfite capable of releasing sulfite after dissolving and sodium chloride releasing chloride ions after dissolving, wherein the mass ratio of sodium sulfite to sodium chloride is 2:1;

[0069] Described additive B adopts Zn, Co, and its mass ratio is 3:2;

[0070] Complexing agent adop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com