A saline-alkali soil improver and its special microcapsule organic acid slow-release preparation

A technology of slow-release preparations and organic acids, applied in organic fertilizers, soil conditioning materials, applications, etc., can solve problems such as aggravation of salt damage, impact on crop yield, soil return to salt, etc., to reduce soil back to alkali, improve improvement effect, The effect of increasing crop yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

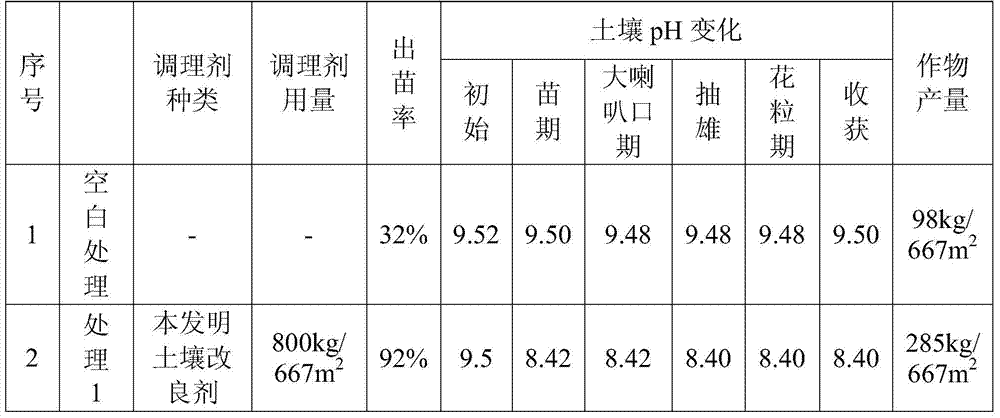

Embodiment 1

[0043] Embodiment 1, preparation slow-release acetic acid, the organic acid preparation of malic acid and saline-alkali soil conditioner

[0044] One, prepare the organic acid preparation of slow-release acetic acid, malic acid

[0045] Prepare the organic acid sustained-release preparation according to the following steps:

[0046] (1) In a 400mL reactor, first add 100 parts of water, 10 parts of acetic acid, 15 parts of malic acid, 15 parts of acrylic acid, 15 parts of acrylamide, and 5 parts of emulsifier SPAN-80 in a weight ratio of 100 parts. Stir to obtain an aqueous phase.

[0047] (2) Add 150 parts of cyclohexane to the aqueous phase obtained in step (1), and shear and stir at 4000 rpm for 30 min to obtain an oil-water mixed phase.

[0048] (3) Under the protection of nitrogen, in the oil-water mixed phase obtained in step (2), add 0.5 parts of initiator azobisisobutyronitrile, raise the temperature at 60 degrees Celsius to slowly initiate the polymerization reaction...

Embodiment 2

[0059] Embodiment 2, the organic acid preparation of slow-release citric acid, salicylic acid and saline-alkali soil conditioner prepared

[0060] One, prepare the organic acid preparation of slow-release citric acid, salicylic acid

[0061] Prepare the organic acid sustained-release preparation according to the following steps:

[0062] (1) In a 400mL reactor, add 100 parts of water by weight, 10 parts of citric acid, 15 parts of salicylic acid, 15 parts of ammonium acrylate, 15 parts of acrylamide, and 5 parts of emulsifier Tween-60 , and uniformly stirred to obtain an aqueous phase.

[0063] (2) Add 150 parts of white oil to the water phase obtained in step (1), and shear and stir at 10,000 rpm for 20 minutes to obtain an oil-water mixed phase.

[0064] (3) Under nitrogen protection, in the oil-water mixed phase that step (2) obtains, add 1 part of initiator ammonium persulfate, raise the temperature at 60 degrees Celsius and slowly initiate polymerization, 1000rpm stirri...

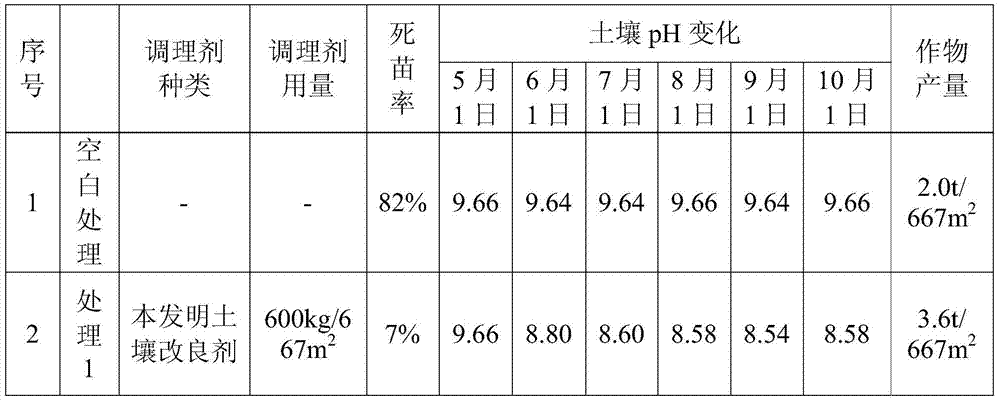

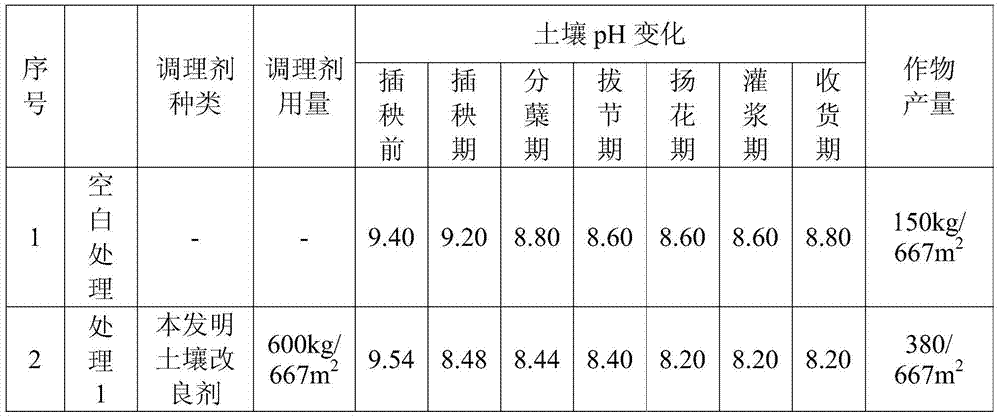

Embodiment 3

[0075] Embodiment 3, preparation slow-release oxalic acid, the organic acid preparation of citric acid and saline-alkali soil conditioner

[0076] One, prepare the organic acid preparation of slow-release oxalic acid, citric acid

[0077] Prepare the organic acid sustained-release preparation according to the following steps:

[0078] (1) In a 400ml reactor, first add 100 parts of water by weight, 10 parts of oxalic acid, 15 parts of citric acid, 15 parts of methacrylic acid, 15 parts of acrylamide, and 3 parts of emulsifier Tween-60 , 2 parts of Nongru 100, stirred evenly to obtain the water phase.

[0079] (2) Add 150 parts of white oil to the water phase obtained in step (1), and shear and stir at 10,000 rpm for 20 minutes to obtain an oil-water mixed phase.

[0080] (3) Under the protection of nitrogen, add 1 part of initiator ammonium persulfate to the oil-water mixed phase obtained in step (2), raise the temperature to 60 degrees Celsius to slowly initiate the polymeri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com