Carboxymethylated ganoderma lucidum polysaccharide, synthesis and purification method and application thereof as tobacco humectant

A technology of carboxymethylated Ganoderma lucidum and a purification method, which is applied in the field of humectants to achieve obvious moisturizing effects, broad promotion and application prospects, and significant industrial application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

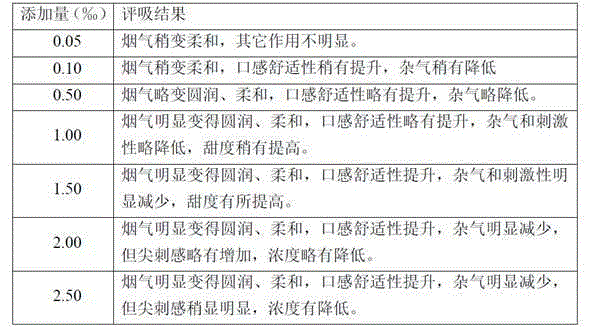

Image

Examples

Embodiment 1

[0022] A method for synthesizing and purifying carboxymethylated ganoderma lucidum polysaccharides, comprising the following steps: adding 14g NaOH and 120mL solvent (ionic liquid / water=1.2:1, mass ratio) to a three-necked flask, stirring at room temperature until the solution is clear, adding 10g The Ganoderma lucidum polysaccharide was vigorously stirred for 20 minutes until fully dissolved, then slowly added 16.8g of chloroacetic acid, stirred and reacted at 65°C for 3 hours, cooled to room temperature, adjusted to pH 7 with dilute acetic acid, precipitated with alcohol, filtered, and collected the precipitate.

[0023] The precipitate was dissolved with an appropriate amount of water, precipitated with 3 times the volume of 95% ethanol, and centrifuged at 4000r / m for 20min. The precipitate was collected again and dialyzed against running water using a dialysis bag. First dialyze with tap water for 24 hours, then dialyze with distilled water for 24 hours, and finally freeze...

Embodiment 2

[0026] A method for synthesizing and purifying carboxymethylated ganoderma lucidum polysaccharides, comprising the following steps: adding 16g NaOH and 120mL solvent (ionic liquid / water=1.2:1, mass ratio) to a three-necked flask, stirring at room temperature until the solution is clear, adding 10g Ganoderma lucidum polysaccharide was vigorously stirred for 30 minutes until fully dissolved, then slowly added 16.8g of chloroacetic acid, stirred and reacted at 75°C for 3 hours, cooled to room temperature, adjusted to pH 7 with dilute acetic acid, precipitated with alcohol, filtered, and collected the precipitate.

[0027] The precipitate was dissolved with an appropriate amount of water, precipitated with 3 times the volume of 95% ethanol, and centrifuged at 4000r / m for 20min. The precipitate was collected again and dialyzed against running water using a dialysis bag. First dialyze with tap water for 24 hours, then dialyze with distilled water for 24 hours, and finally freeze-dry...

Embodiment 3

[0030] A method for synthesizing and purifying carboxymethylated ganoderma lucidum polysaccharides, comprising the following steps: adding 18gNaOH and 120mL solvent (ionic liquid / water=1.2:1, mass ratio) into a three-necked flask, stirring at room temperature until the solution is clear, adding 10g Ganoderma lucidum polysaccharide was vigorously stirred for 20min until fully dissolved, then slowly added 16.8g chloroacetic acid, stirred and reacted at 85°C for 4h, cooled to room temperature, adjusted to pH 7 with dilute acetic acid, precipitated with alcohol, filtered, and collected the precipitate.

[0031] The precipitate was dissolved with an appropriate amount of water, precipitated with 3 times the volume of 95% ethanol, and centrifuged at 4000r / m for 20min. The precipitate was collected again and dialyzed against running water using a dialysis bag. First dialyze with tap water for 24 hours, then dialyze with distilled water for 24 hours, and finally freeze-dry to obtain l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com