Mould with mechanical buckles

A machine and mold technology, applied in the field of molds with mechanical buckles, can solve problems such as product sticking, nylon shutter wear, mold scrapping, etc., to reduce the number of mold repairs, prevent product sticking, and improve quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

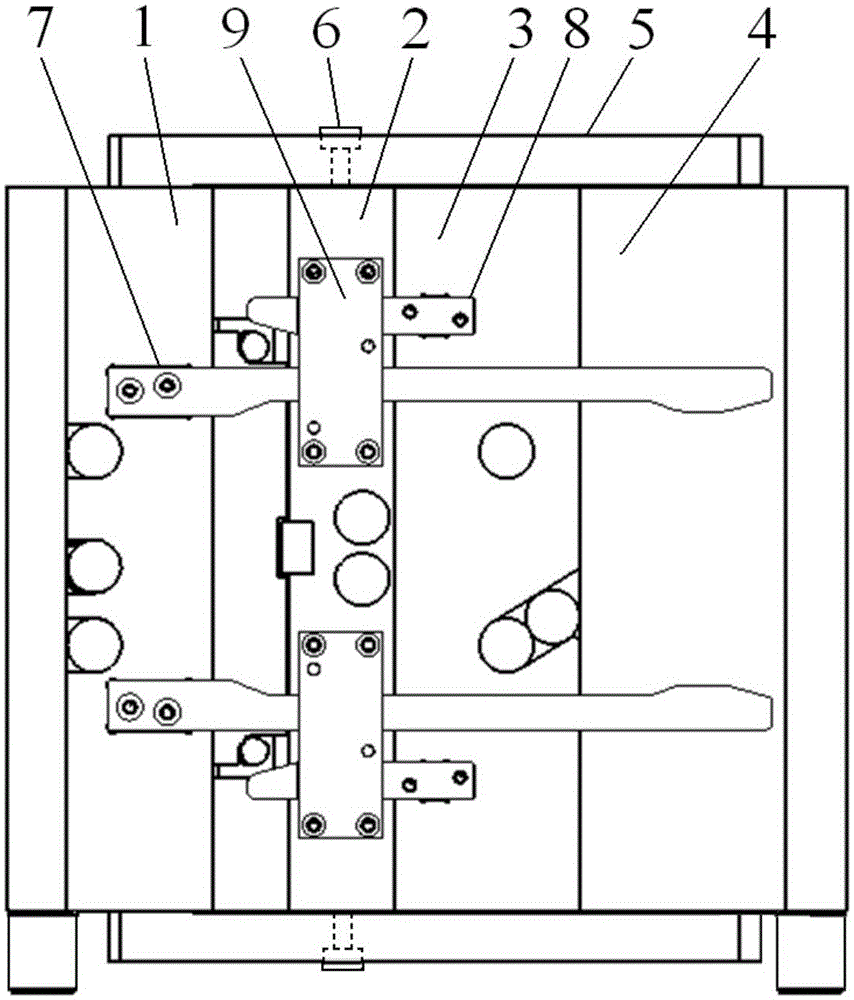

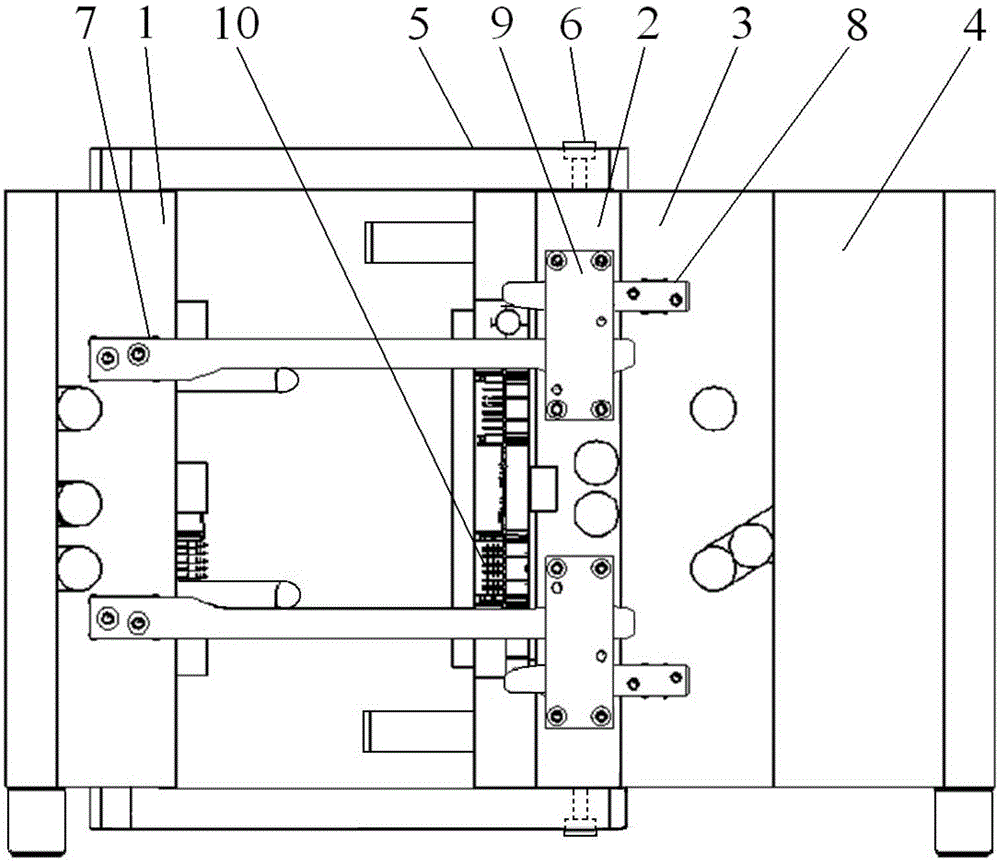

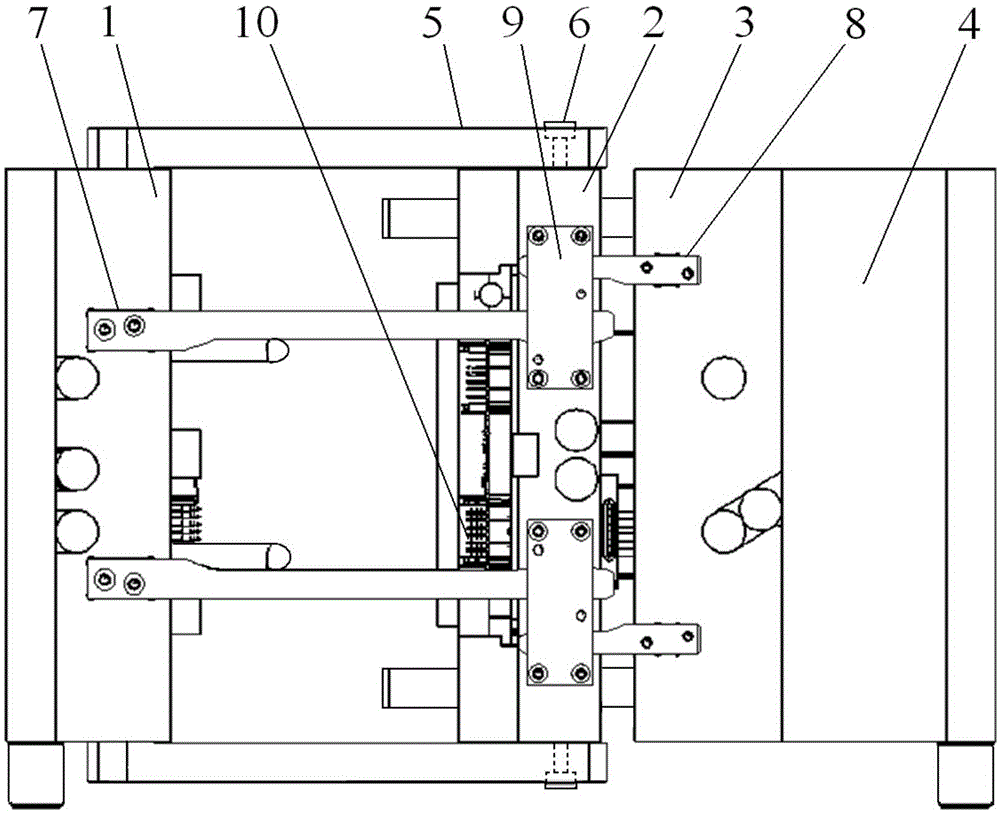

[0013] Such as figure 1 , figure 2 and image 3 As shown, a mold with a mechanical buckle is composed of a front mold 1, an A plate 2, a B plate 3 and a rear mold 4 from left to right; the upper and lower sides of the front mold 1 are respectively fixed with pull rods 5; The upper and lower sides of the A bar 2 are each provided with a guide post 6; the pull rod 5 is sleeved on the guide post 6 and the pull bar 5 can move left and right under the guidance of the guide post 6; the front mold 1 A long mechanical buckle 7 is fixed on the top; a short mechanical buckle 8 is fixed on the B board; a mechanical buckle 9 for the long mechanical buckle 7 and the short mechanical buckle 8 is fixed on the A board.

[0014] The working principle of the mold with mechanical buckle of this embodiment: when opening the mold, the front mold 1 moves to the left with the pull rod 5; Move to the left, because the short mechanical buckle 8 and the mechanical buckle 9 are used together, so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com