Preparation method for snake bone device of endoscope

An endoscope and snake bone technology, which is applied in the field of preparation of snake bone devices, can solve the problems of high scrap rate, high production cost, low production efficiency and the like, and achieve the effects of good assembly quality, low production cost and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

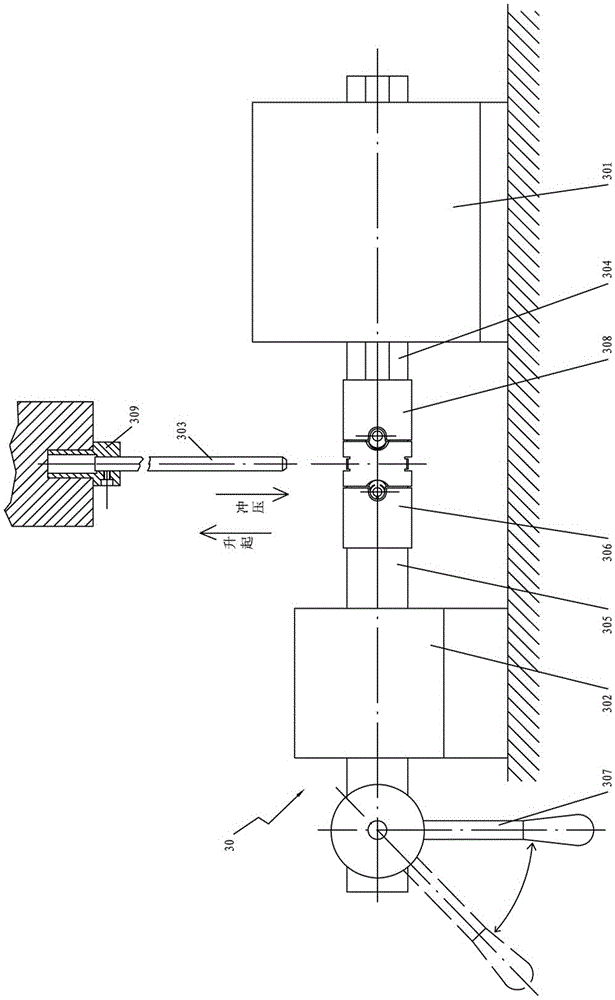

[0053] The present invention will be further described below in conjunction with the accompanying drawings and given embodiments, but is not limited thereto.

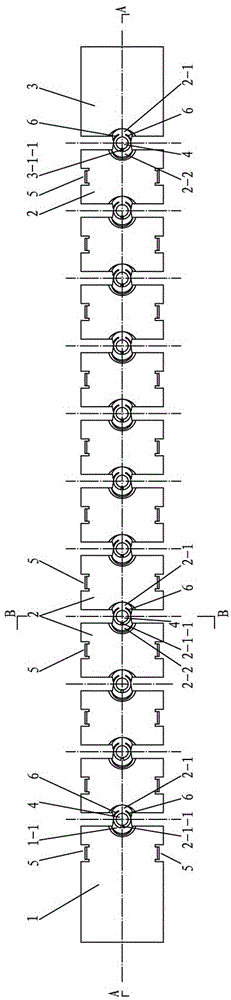

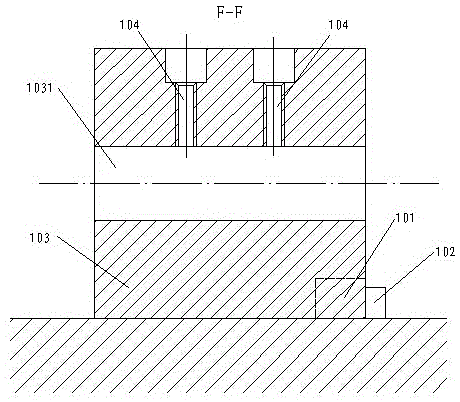

[0054] Such as Figure 1-13 Shown, a kind of snake bone device model of endoscope is the preparation method of BS type series, and described snake bone device comprises snake bone front segment ring 1, snake bone rear segment ring 3, 22 connecting pin shafts 4 and is connected in The specific preparation steps of the 10 snake bone middle segment rings 2 between the snake bone front segment ring 1 and the snake bone rear segment ring 3 are as follows:

[0055] 1. Material selection and preparation before processing:

[0056] a. The inner diameters of the anterior segment ring 1 of the snake bone, the middle segment ring 2 of the snake bone and the rear segment ring 3 of the snake bone are all 8.5 mm in outer diameter and 8 mm in inner diameter, and the stainless steel pipe is selected;

[0057] b. The connecting pin 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com