Flexible bending die with wheel preventing deformation

A bending mold and anti-deformation technology, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of bending and deformation of condensation pipes, and achieve the effect of eliminating damping and avoiding hard points or bending and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

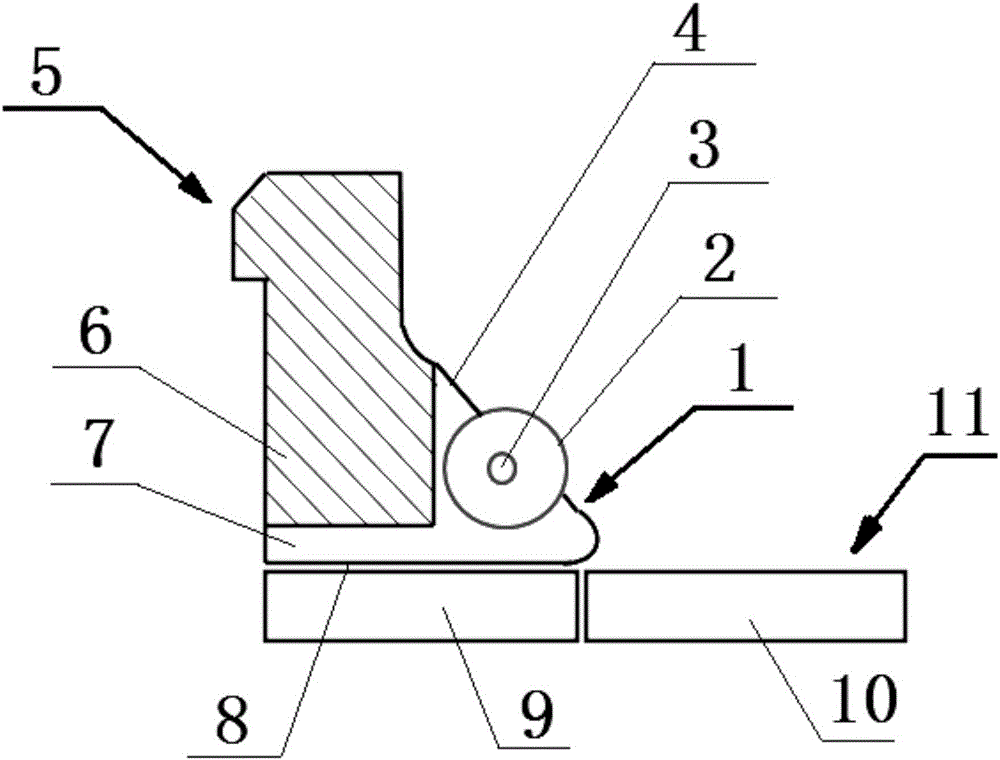

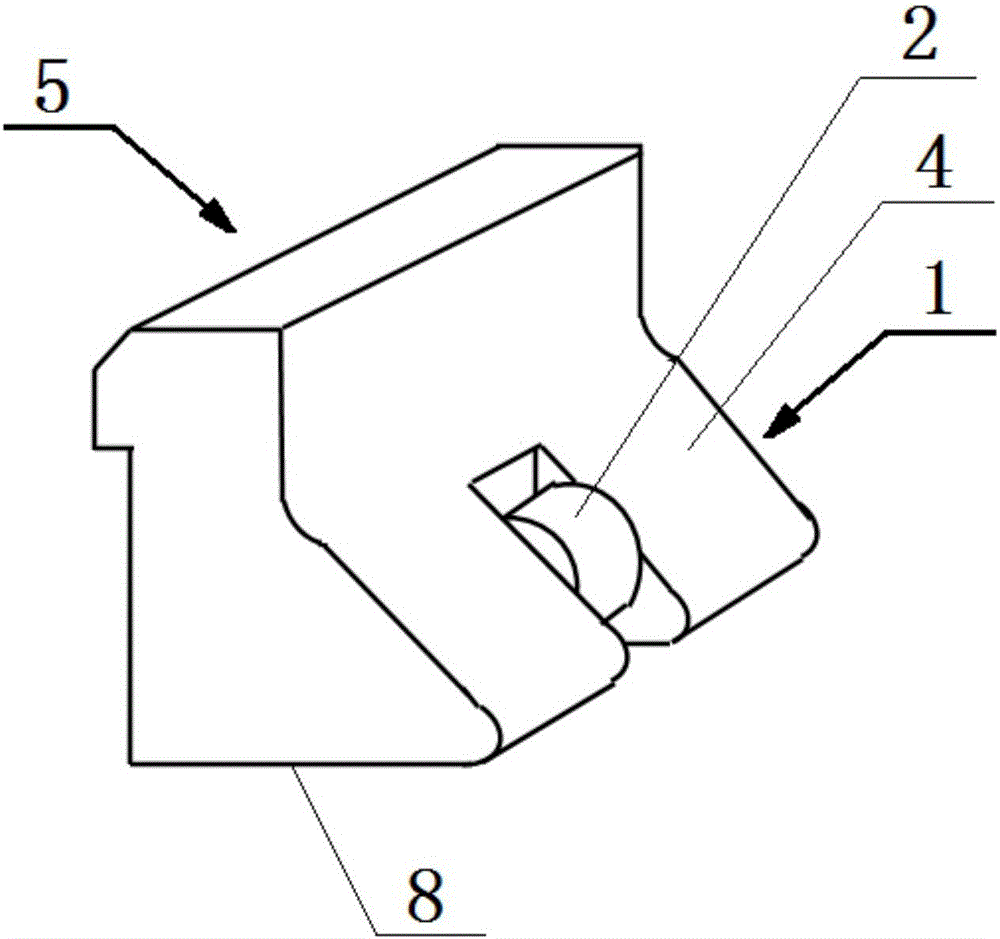

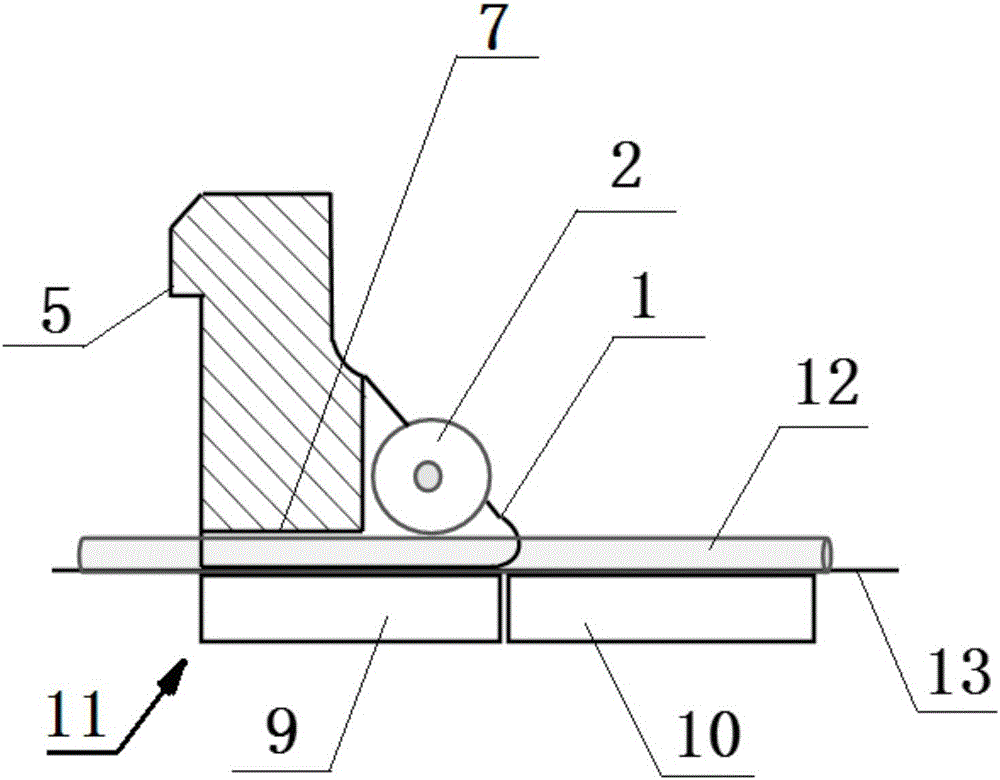

[0020] like Figure 1 to Figure 5 A rolling anti-deformation flexible bending die shown:

[0021] Including upper mold 5 and lower mold 11;

[0022] The lower mold 11 includes a lower mold base 9, and the front end of the lower mold base 9 is hinged with a rotating arm 10;

[0023] Described patrix 5 comprises the patrix 6 that is positioned at the top of patrix 9, and the center of the bottom of patrix 6 has a through groove 7 that runs through front and back, and the front end of patrix 6 that is positioned at both sides of pass groove 7 is respectively provided with A punch 1, a rotating shaft 3 is installed between the two punches 1, and a roller 2 is installed on the rotating shaft 3.

[0024] The punch 1 is wedge-shaped, including a bottom surface 8 in the shape of a horizontal plane, and an inclined surface 4 inclined to the bottom surface 8 .

[0025] The diameter of described roller 2 is 30 millimeters, long 10 millimeters;

[0026] The distance between the roller...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com