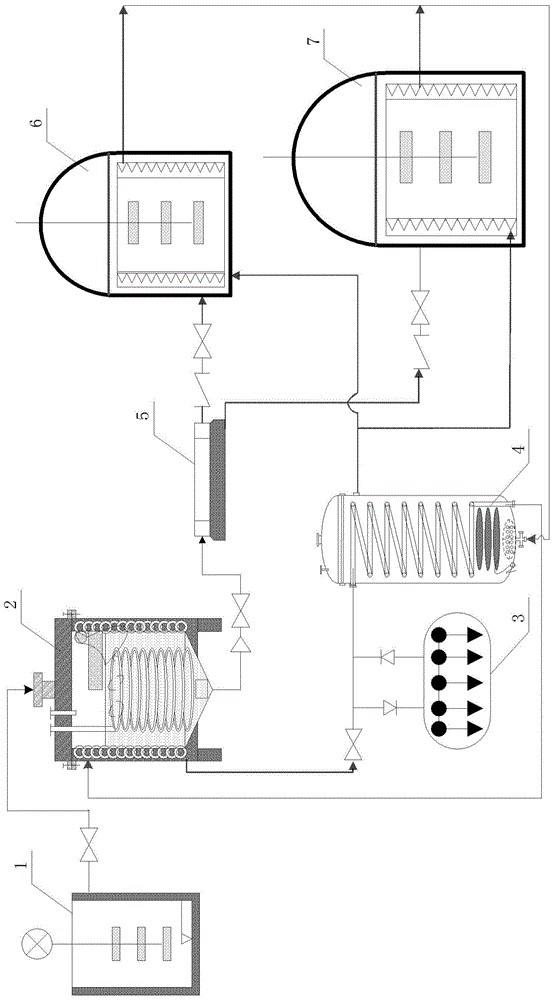

Kitchen waste phase separation production device and production method

A kitchen waste and phase separation technology, which is applied in the field of solid waste recycling, can solve the problems of easy acidification collapse of anaerobic system and difficulty in long-term stable operation, so as to improve the service life of equipment, save excessive water loss of materials, The effect of equipment maintenance cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0058] A specific example is as follows:

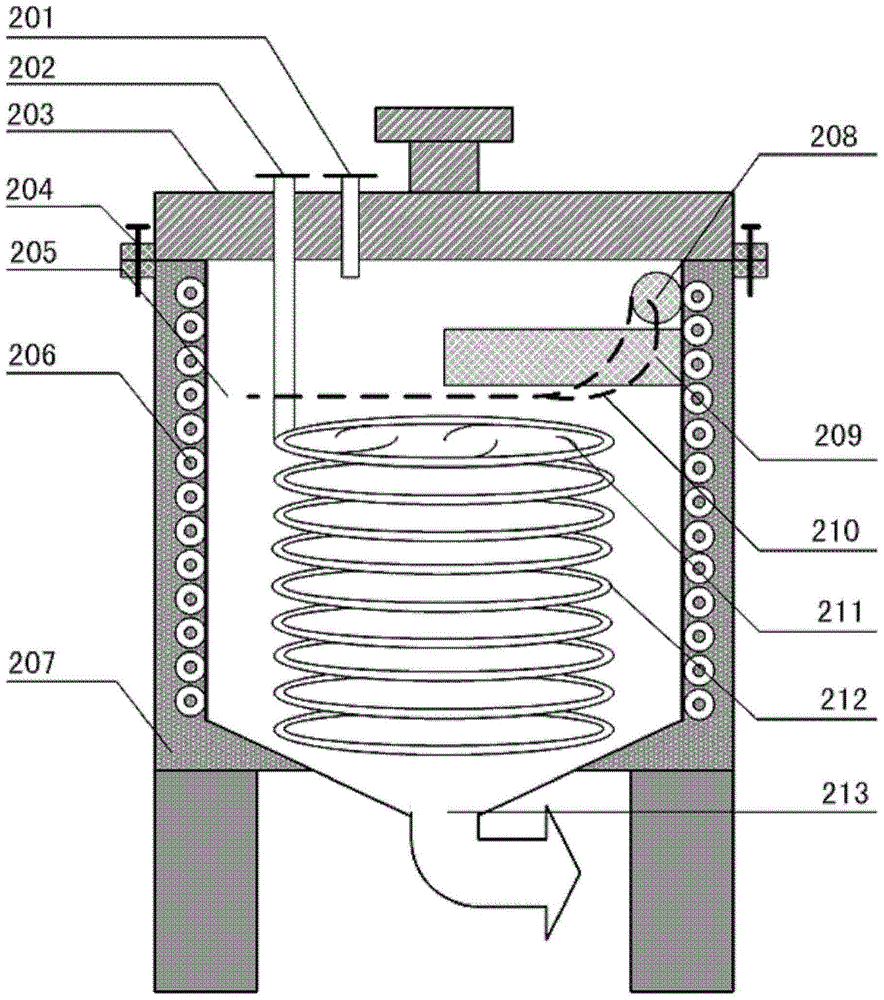

[0059] The kitchen waste from the canteen is first manually sorted to remove large refractory materials such as chopsticks, bones, and plastic bags, and then broken into pieces before entering the blending pool 1. It is prepared from tap water or anaerobic fermentation tank reflux biogas slurry, adding 50% water, and the pH value is between 6 and 8. The feed liquid is pumped into the 10L steam spin wet heat pretreatment tank 2 through the slurry pump for pretreatment. The pretreatment temperature is 150°C and the heating time is 30 minutes. The pump outlet is equipped with an in-situ pressure gauge and a check valve is installed behind the pump.

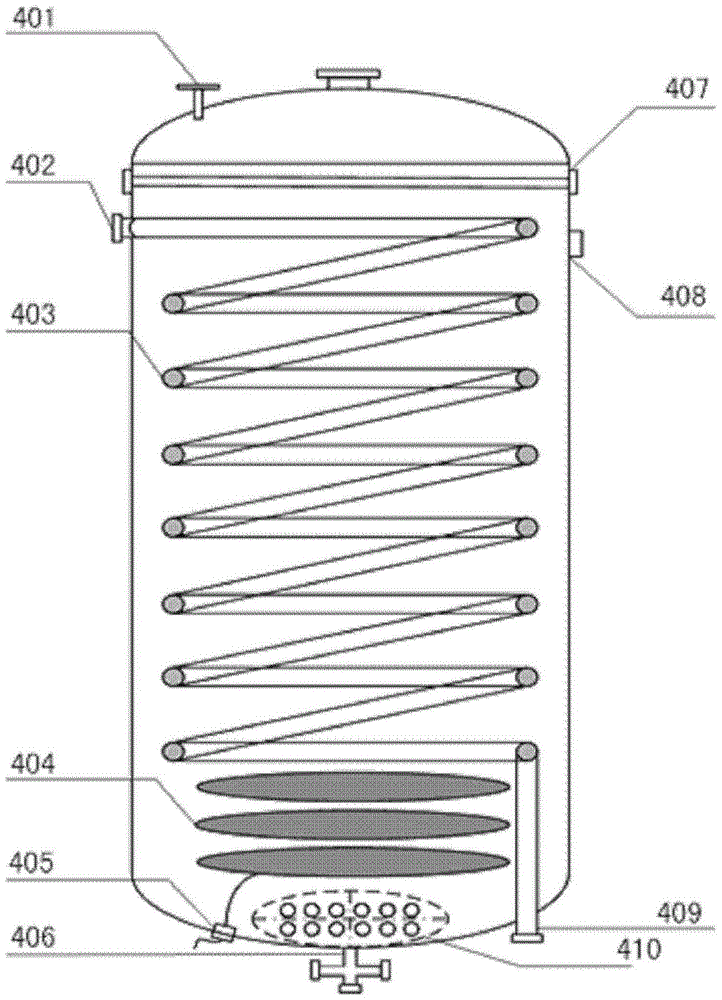

[0060] At the same time as the damp heat pretreatment is completed, the automatic degreasing machine and cooling system are started to recover the grease, and the excess heat enters the heat accumulator 3, and the heat is stored and released through the three-item heat exchange self-insulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com