High Efficiency Raymond Mill

A Raymond mill, high-efficiency technology, applied in the direction of grain processing, etc., can solve the problems of increasing the energy consumption of the Raymond mill system, blocking the surrounding air intake channels, and reducing the crushing efficiency, so as to achieve small resistance, reduce over-grinding, and improve The effect of crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

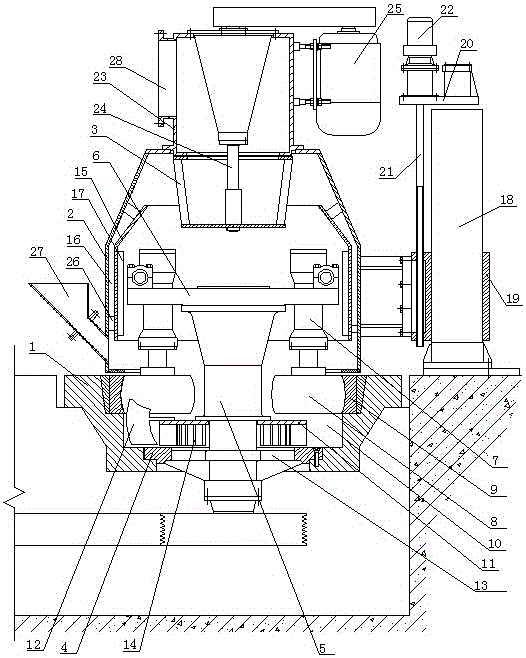

[0027] Such as figure 1 As shown, the high-efficiency Raymond pulverizer includes a base 1, which is fixed in the ground trough by anchor bolts, and the top surface of the base 1 is as horizontal as possible with the ground to facilitate installation and maintenance. An outer cylinder 2 is provided above the machine base 1. The outer cylinder 2 is connected to a supporting device. There is a set gap between the lower end of the outer cylinder 2 and the top surface of the machine base 1. The size of the gap is based on its air intake As far as it does not affect the work of the whole machine, try to use a small gap; the setting of the gap can block the noise from being transmitted from the base to the outer cylinder, so as to reduce the noise from the outer cylinder. The support device is a rotatable and liftable support device, including a pillar 18 provided on the outside of the outer cylinder 2, and the pillar 18 is connected with the outer cylinder 2 and can slide up and down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com