Long-acting self-lubricating big oil cylinder

A high-oil, long-term technology, applied in the direction of engine lubrication, engine components, mechanical equipment, etc., can solve the problems of wear and tear of parts, affecting product quality, polluting the working environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

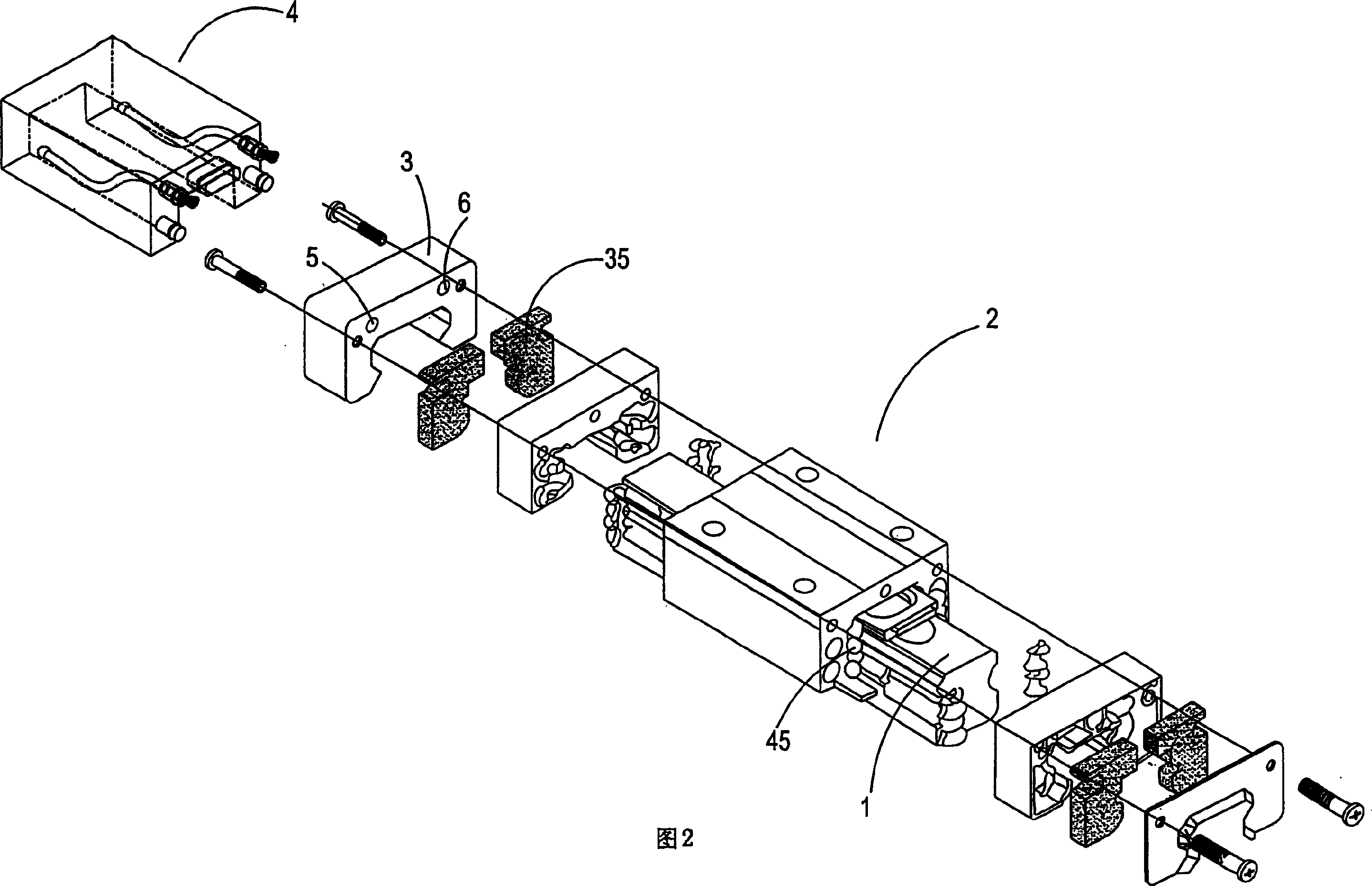

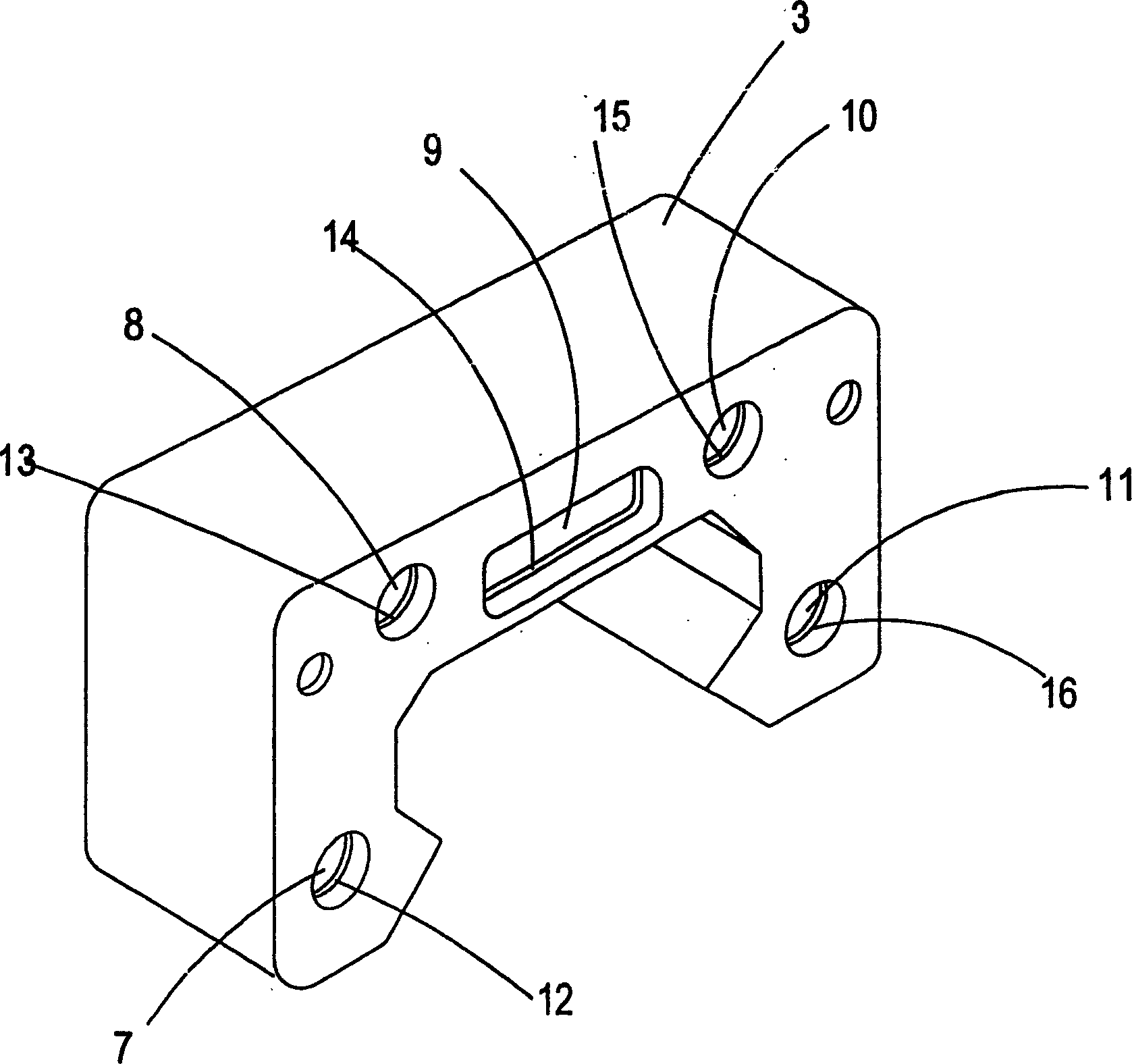

[0013] as attached figure 1 to the attached Figure 8 As shown, the present invention is composed of a slide rail 1, a sliding seat 2, a connecting seat 3 and an oil storage tank 4, wherein the oil storage tank 4 is mainly composed of positioning columns 24, 25, 26, 27, 28, oil cores 33, 34 and heavy balls 31, 32; a connecting seat 3 is provided on one side of the sliding seat 2, and several positioning holes 7, 8, 9, 10, 11 are arranged in the connecting seat 3, which can be used for protruding installation on one side of the oil storage tank 4. The positioning posts 24, 25, 26, 27, and 28 of the locating hole are embedded in it to achieve the effect of quick installation and replacement of the oil storage tank 4 during use; the inner edges of the positioning holes 7, 8, 9, 10, 11 and the positioning posts 24, 25, 26, 27, 28 are provided with grooves 12, 13, 14, 15, 16 and ribs 17, 18, 19, 20, 21 on the outer edges, respectively, through the grooves 12, 13, 14, 15 , 16 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com